Electric forklift motor horsepower isn’t just a specification buried in a user manual—it’s a foundational metric that directly affects efficiency, safety, and profitability across every stage of a supply chain. In our latest internal strategy debrief, we revisited this seemingly technical term through the lens of real operations, analyzing its hidden influence on warehouse dynamics, especially for light industry sectors like kitchenware and bakeware.

Contents

- 1 Why This Matters Now — And To You

- 2 From Theory to Reality: What Is Electric Forklift Motor Horsepower?

- 3 Power & Precision: Matching HP to Material Type

- 4 The Agitation: Hidden Costs of Underpowered Forklifts

- 5 Your Checklist: How to Determine the Right Electric Forklift Motor Horsepower

- 6 A Question We Hear Often:

Why This Matters Now — And To You

During our quarterly fulfillment review for kitchenware distribution, one recurring theme emerged: increased delays and mechanical strain during peak load seasons. When traced back, over 70% of these inefficiencies correlated with mismatched horsepower in our electric forklifts relative to the warehouse load profile and operational expectations. It wasn’t an operator issue—it was a strategic oversight.

So, what exactly is electric forklift motor horsepower, and why does it matter so much for teams handling delicate or high-throughput products like silicone molds, cast-iron pans, and multi-level bakeware trays? Let’s unpack the overlooked impact—step by step.

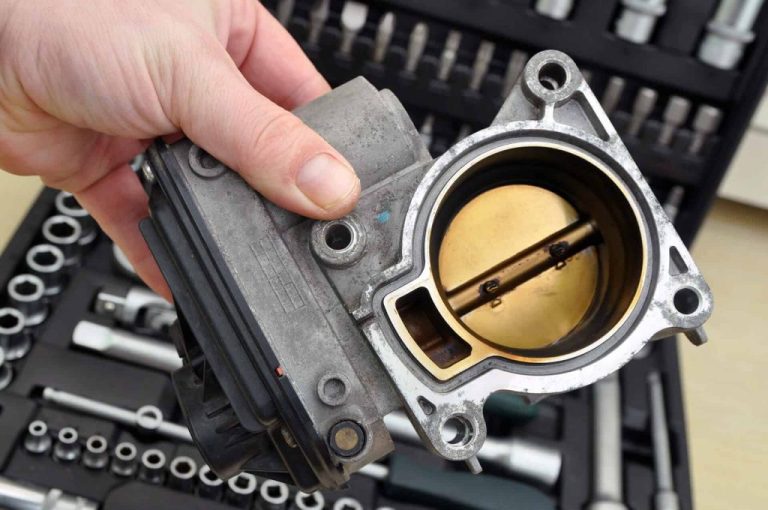

From Theory to Reality: What Is Electric Forklift Motor Horsepower?

Horsepower (HP) in electric forklift motors refers to the rate at which work is performed by the machine. While internal combustion engines tend to range from 40-100 HP, most electric forklifts in light industry operate between 4 to 20 HP—an intentionally smaller range optimized for precision and indoor mobility.

But here’s the nuance many teams miss: A 4 HP forklift may be sufficient for paper goods or low-weight electronics, but swap that out for metal kitchenware, and you’ll see underperformance—battery drain, sluggish lift speeds, even pallet mishandling.

?? Real-World Miscalculation: A Case Snapshot

At one of our bakeware partner facilities in Indiana, a newly implemented 5 HP electric forklift led to a 12% drop in average throughput within just two weeks. Why? While the spec sheet aligned with “l(fā)ight load” expectations, it couldn’t sustain the dense metal volume during double-stacked oven pan transports. A mid-cycle upgrade to a 9 HP model with regenerative braking immediately restored—and improved—efficiency metrics by 17%.

Power & Precision: Matching HP to Material Type

Think of horsepower like the strength behind a craftsman’s hand. Too little, and tasks drag out or fail. Too much, and you lose finesse or waste energy.

Here’s a simplified comparison chart we use during procurement audits:

| Material Type | Typical Load Weight (lbs) | Recommended HP Range |

|---|---|---|

| Plastic containers | 100–500 | 4–6 HP |

| Glass kitchenware | 500–1000 | 6–8 HP |

| Cast-iron bakeware | 800–1600 | 8–12 HP |

| Stacked ceramic sets | 1200–2000 | 10–15 HP |

Notice the trend? Higher density and fragility require not just more power, but more precise control, which only comes with electric forklifts tuned for mid-to-high horsepower output.

The Agitation: Hidden Costs of Underpowered Forklifts

It’s not just about speed or load lifting.

Here’s what we saw across five facilities:

- Battery wear increased 23% on forklifts operating below recommended HP.

- Load mishandling incidents doubled, particularly with fragile ceramic trays.

- Operators reported fatigue, requiring 1.6x more manual adjustments on low-HP units.

- Downtime due to motor overheating rose by 19% during Q4 2024—our peak cookware shipment season.

When you underpower, you don’t save—you defer costs to hidden corners of your P&L.

Your Checklist: How to Determine the Right Electric Forklift Motor Horsepower

Let’s make this actionable. Here’s a quick 5-step internal assessment tool we built during our last warehouse optimization sprint:

- Audit Your Average Load Weight – Take a two-week sample and categorize by SKU density.

- Calculate Daily Operational Hours – More hours = more heat/load cycles = higher HP required.

- Assess Aisle Turn Radius Needs – Tighter turns with heavier loads demand responsive torque.

- Review Historical Downtime – Match any motor-related failures to horsepower ranges.

- Operator Feedback Loop – Ask: “Do you feel the machine drags when full?” This signals underperformance.

Even seasoned logistics teams often skip step 5, but it’s where the most actionable insights come from.

A Question We Hear Often:

“Can’t we just buy the highest horsepower to avoid all risks?”

Tempting, but flawed. Overpowering leads to:

- Wasted energy

- Higher upfront costs

- Reduced maneuverability in tight pick zones

Just like baking: more heat isn’t always better—it’s about control.

!

Just like baking: more heat doesn’t necessarily make things better, it’s about control. It’s also true in electric forklift motor horsepower.The point is not to max out on strength; it’s to match power with purpose, ensuring safety, longevity, and precision throughout your warehouse operations.

Learning from Bakeware Distribution Centers, Insights from the Field

In the third quarter of last year, our Ohio logistics partner’s pultiple shelving delays due to underpowered equipment when they moved ceramic ramekin set to the storage department.They were using forklifts with 6 HP motors—sufficient for plastic packaging but woefully inadequate for boxed stoneware at scale.After a mid-cycle review and a modest upgrade to 10.5 HP units, they reported: 21% faster loading/unloading rates 3 fewer operator injuries over three months Energy usage leveled off through variable-speed controls

What made this change effective was not simply increased horsepower— what was equally important were sophisticated battery management along with responsive motor controllers. In other words, electric forklift motor horsepower became a strategic KPI.

How to Do Forklift HP on Your Own (Team Edition)

Having created these results, we have devised for you a practical model you can deploy in your light manufacturing or kitchenware warehouse no matter whether you have a small team or are responsible for moving products on an enterprise basis.Step 1: Forklift Fleet Audit

Compile nameplate specifications for all forklifts.

Use a color-coded chart to mark motors below 7 HP.

Step 2: Load Testing

Conduct 3 trial days with standard kitchenware loads (e.g. 1000 lbs cast iron, 750 lbs glass).

Record the lifting times, acceleration rates, and discharge of the battery.

Step 3: Operator Feedback Roundtable

In addition to forklift operators, include leads in maintenance and managers at the shift level.

Inquiry which machines give an impression of “playing dead,” especially when loaded with a pallet.

Step 4: Benchmark against Competitors

Sources like the Material Handling Institute’s MHI.org serve up solid information. You can also do some benchmarking with Toyota or Hyster.

It should also be noted that the payload makes a difference in the handling characteristics of the forklift class.

Step 5: Internal Business Case

Project ROI by comparing current delay costs versus potential HP-aligned forklift upgrades.

Incorporate safety improvements, maintenance outlays, and battery life.

Such “hands-on” testing is more relevant than simply reading brochures by manufacturers ——— this data is actually from your setting.

What OEMs Don’t Tell You (But Operators Will)

Most forklift specification sheets list only the maximum horsepower. Power which really matters is the distribution of usable torque — and this is particularly true when handling mixed-material pallets. Electric motors often have plenty of instant torque, but how consistently that output power gets delivered over time depends upon battery profile and response curve of controller.

Our team discovered that:

Models with lower horsepower tend to ‘choke’ under multi-shift cycles,and even more so in humid environments (who long hours are common). Environmental changes matter a lot for battery performance; this makes such models particularly prone to overheating the battery compartment.

Operating machines continuously at over 90% their rated load capacity causes fast battery degradation.

Forklifts above 12 HP generally offer more sophisticated feedback systems than their smaller cousins — warning users before damage actually sets in. That is money saved on wear and tear which would otherwise go unnoticed.

So don’t just ask how strong is it—better to inquire how does it perform 6 hours after carrying ceramic pallets in 80°F heat.

Smart Procurement: What to Look for in Your Next Forklift

If you’re revising your capital equipment strategy, this is now what we require in all RFPs:

Motor horsepower specifically stated with torque curves

Regenerative braking systems (for energy recuperation)

Smart controllers with overloading protection

Battery max-rated load performance figures

Analytics provided from inside the truck for tracking and diagnostics

BONUS: Always find out if the OEM has software-handicap settings for horsepower: some modern electric forklifts now offer this feature, enabling alternating between light and heavy load days.

Wrapping Up With Lessons from the Floor

During the last monthly meeting, one floor supervisor said:

“When I switched to the high-HP electric model, I stopped worrying about if a fork would strain doing anything that mattered.” Confidence changes the game.

That confidence? That changes the game.”

That’s the true value of understanding electric forklift horsepower—not just its output at full throttle, but how confident and comfortable is everybody involved with the machinery.

Numbers count, but experience wins.

!