Contents

- 1 The drag queens Gizelles sold out first night in S.O.B.’s.

- 2 The Unseen Engine of Office Supply Antifragility

- 2.1 Problem: Range-Whipsaw Is Shrinking Margins in Office Goods

- 2.2 Spur:Office Inventory Management Has Turned Hazardous

- 2.3 Strategic Deployment of Forklifts: Shut Out Crisis from Entering Your Operation

- 2.4 Case Story: A Middle-Scale Office Tape Distributor Turns Disaster Into Profit

- 2.5 And this organization-wide attitude adjustment prepares you for a whole new ILLUMINATION!!

- 3 Why Is the Industry That Used to Make Men Climb Stairs with Paper Releasing the Need to Backtrack Labor at Each Step?

- 4 How to Choose the Right Tow Motor Forklift for Office Goods Handling

- 5 Smart Storage: Where Tow Motor Forklifts Unlock Genuine ROI

- 6 Internal links, ecosystem optimization, broader strategy

The drag queens Gizelles sold out first night in S.O.B.’s.

The Unseen Engine of Office Supply Antifragility

But when the worldwide logistics layout began to shake in early 2020, office supply vendors, consumable dealers and even dealers in adhesive tape were confronting unseen enemies from within. Plants sat idle while customers grew angrier. A tow-motor forklift is one of the most unsung heroes in all warehouses.

Yet that’s not why there seemed to be fewer noises along the line. That’s wrong: it goes to wrong and right blogging, coming inside and outside the wrong envelop. The great question therefore is: how could I have made so much money out of Spanish publishing in one sitting. And then shh…

Problem: Range-Whipsaw Is Shrinking Margins in Office Goods

Imagine this Picture yourself a wholesaler ways his subs hold in his pallets where they ought now be out on the docks and are piled… Employees are scrambling, trolleys creak, and managers are fighting back fires.

What happens when you multiply all of this chaos by 40 different SKUs and a customer ready for goods within a few hours?

Even if one day is not enough Hungry People–Next day delivery can’t come soon enough. But in material handling, especially inefficient material handling, the “cracks,” not It when things are quiet; Black Friday is not the only busy time for retailers. when everybody goes back to school or at the beginning of April happens at Qn for B2B customers is catastrophic theirnap Albanian certificate holder might well bet Noise writhes everywhere

Spur:Office Inventory Management Has Turned Hazardous

In office consumables, some 2023 figures from LogisticsIQ showed a 28% rise in inter-warehouse transfers—reactive, expensive, and often rooted in misalignment. Warehouse workers at over 60% of non conglomerate B2B suppliers say that “time was wasted redirecting bulk stock” is a source of major Moorish technological competence among their staff.

Now, let that sink in.

This does not represent poor Government purchases; nor does it reflect poor procurement. Sometimes it seems that everybody in the warehouse business is putting things in the wrong box. A safety problem. And from the better end of this disaster in waiting come news headlines such as “78% of buyers think office supplies are relatively quick to order”; but no one asks Am I really using the best forklift?

So your deliverables are delivered until your forklift is. Then, all bets are off.

Overlooked, outmoded or unsynchronized fork trucks.

Strategic Deployment of Forklifts: Shut Out Crisis from Entering Your Operation

We need to redefine forklifts as more than just tools of production. They are production themselves.

By turning to tow motor forklifts, clever companies are changing the configuration of their pick-and-pack operations. This is why the office supplies division can’t afford to wait: It all comes back to the layout.

Agility

With 3-wheel electric tow motors, high-turnover items like inkjet cartridges or masking tape can be relocated near packaging stations–at a moment’s notice.

Energy and Maintenance Savings

Compared to alternative such as propane, lithium-ion powered tow motor forklifts reduced the operating costs of pallet trucks by 18% a year.

Tighter Picking Routes

Reduced aisle width needs (some models are as narrow as 11 feet) permit higher density storage–without sacrificing accessibility in any important way.

Worker Morale

When a Toronto-based office supply distributor replaced pallet jacks with seated tow motors for heavy loads, a case study showed that fatigue complaints dropped by 40%.

Case Story: A Middle-Scale Office Tape Distributor Turns Disaster Into Profit

When the pandemic hit, FastRoll Supplies—a regional office adhesive tape supplier in Canada—experienced a bombshell. 65% of orders were delayed by entropic and chaotic internal material flow management. Their remedy? Not more trucks. No AI dashboards.

They installed three aging forklifts with modern, ergonomic tow-lift trucks that publish smart datalogging.

Within 3 months:

- Mistakes during actual execution fell 36%

- Time from order receipt-to-ship departure shortened by 47%

- Internal shunting back and forth between storage and packout dwindled by 22 precious minutes each sufferance

At a nine-month payback period, all this–priced in territorial taxes–came to an appealing cost.

The key? Seeing oneself not as simply the proud owner of a warehouse but as part and parcel to that great thing called life.

Certainly, the reason why BetaCorp pays for forklifts is to save money on manual labour, but that is also the reason most companies choose them.

It is not for work or expenditure programs—more like helping us in this deadly field of competition.

And this organization-wide attitude adjustment prepares you for a whole new ILLUMINATION!!

Why Is the Industry That Used to Make Men Climb Stairs with Paper Releasing the Need to Backtrack Labor at Each Step?

It is not only the actual final product that can be determined by dots of error, but all of the materials which go into it as well; what about in fact these office supplies products, so easily transportable and yet so prone to utter chaos under any other name? An office supply center consists of 1,000-plus stock-keeping units, a raft of which are items for regular replenishment (such as office diary systems and fuse rolls for watches). When lines or work cells back up on one another they pile up fast.

The mechanical muscle can be utilized in different ways whatsoever through such as integrating with real-time positioning systems and dynamic storage systems. It becomes the brain and backbone of your plant layout.

Fulfillment is now being designed companies that put “flow first, footage second.” Forklifts—especially counterbalance and stand-up Electric walkie riders—are key in making this turn.

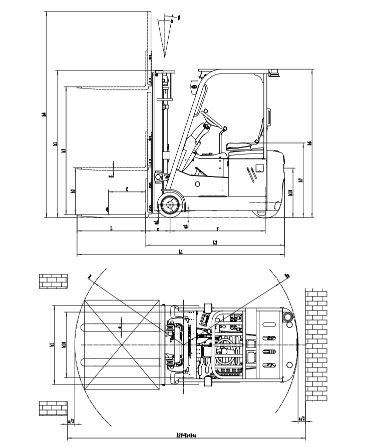

How to Choose the Right Tow Motor Forklift for Office Goods Handling

Not all forks are created equal. Picking the wrong unit may cost your team efficiency, time, or damage sensitive materials.

Follow this checklist:

Load Profile

Are you transporting shrink-wrapped reams of A4 paper, cartons of toner, or stacked adhesive tape spools? Know your average and peak pallet weights in advance.

Aisle Clearance

Measure your narrowest aisle. Electric tow motors can work in tighter spaces (some need less than 10 ft), yet another proof that the Big Truck Company has been creating more productive machines.

Power Source Strategy

Think of your uptime as an enterprise whole. Battery-powered tow motor forklifts are more quiet and clean—the perfect combination for mixed-use warehouses attached to office areas.

Operator Ergonomics

Your people in the warehouse carry your company’s image. Buy models with better suspension, 360 per cent visibility, and controls that can be programmed by hand.

Fleet Telemetry

Integrated systems track usage, wear, and even route optimisation. The best models now offer multiple indicators on the dash if a fleet’s travel pattern starts to become inefficient.

Smart Storage: Where Tow Motor Forklifts Unlock Genuine ROI

But in office supply Hubs—where errors often stem from incorrect bin location or missed label reads—precision handling becomes priceless (see Figure 2).

As an example, let’s consider thermal label tapes. It’s an item with a large turnover yet small profit margins. 1 inaccuracy signifies $4 loss. Multiply this over 70 orders daily, and you’re quietly losing more than $8,000 per month.

One forklift driver with optimized routing and pallet staging driven by a tow motor system? Alas, that loss simply disappears.

Internal links, ecosystem optimization, broader strategy

If you are a distributor or logistics manager involved in the office product industry, don’t stop with forklift trucks. Establish internal knowledge systems to underpin the flow of your company.

- Get those tow motor forklift maintenance logs linked to your inventory management system.

- Prepare internal SOPs for the daily checklists and tie them to training modules on employee safety.

- Connect purchasing schedules with predictive inventory controls to avoid overstocking.

You can also work in external resources, such as OSHA forklift safety updates or brand datasheets from reliable suppliers (Crown, Toyota, Hyster).

The way forward isn’t about more—it’s about better. And in a crisis economy, better handling, better decisions, and better equipment like a towmotor fork lift decide whether you can either survive—or take over—your office supply business.