Forklift’s DC Motor Technology: A Revolutionary Balance

In the realm of modern logistics, forklift technology with DC power is turning things completely upside-down. Especially in office supply and equipment operations it is more than an upgrade

Your warehouse workflows management, already is in the crosshairs of this epochal shift. If you are responsible for an inventory of office printers, shredders and bulk stationery, there’s a big chance that what you have is really increasing your costs without you realizing it.

Losing Profit? No, You’re Losing Blood Slowly

Let’s start with this basic fact: In conventional-founded, office product distribution centers, forklifts that resemble traditional ones in design are undoubtedly outdated. They consume excessive amounts of energy, overheat and break down frequently. Still, many businesses have to use them because… well, they’ve always done so.

Of DC Motor Technological revolution transforming industry:

One of the first things you notice upon inventorY this new forklift is that it looks pretty much like an ordinary electric truck. Scratch beneath surface and you’ll find however very sweeping changes forklift

This guide will study these issues: the real costs of ignoring the shift and also just how market leaders make use of DC-powered logistics today; is there another way forward that you have overlooked until now perhaps to give your company that edge?

The Problem: Hidden Loss in Office Equipment Warehousing

Before we get into the nitty-gritty of how a DC motor-driven forklift works, let’s take a look at what’s wrong with your current setup in terms of silent enemies.

Downtime for Maintenance: Internal combustion forklifts can break down frequently due to their intricate drives. Repair times delay your deliveries.

Energy waste: A visit to a factory outlet will reveal that AC-powered and IC forklifts consume more energy and leak via heat and vibration.

Noise pollution can be a real scourge. In a closed environment such as where you’re assembling orders or processing paper (think of paper shredder warehouses ), noise levels matter greatly — particularly if on the days when there 9is a shared operator.

Each of these drains takes a small portion of productivity. As a result, you don’t know where your money goes — but your logistics staff can feel it in every dispatch that is late or motor which goes up during operation.

Case Analysis: The Agitator from a Mid-Sized Office Supplier

A Midwest office supply company, for example in 2022, DataDesk Supplies Ltd (shortened to DataDesk Supplies), started a three-month study of the traditional LPG-powered forklift versus a new type of DC motor forklift regarding their paper shredding equipment section.

Electricity Used Less: 19.7 percent drop in electricity bills

Maintenance Calls Down: 3 from 12 per month!

Operator Complaints: decreased by over 65%, due to better handling and less cabin noise.

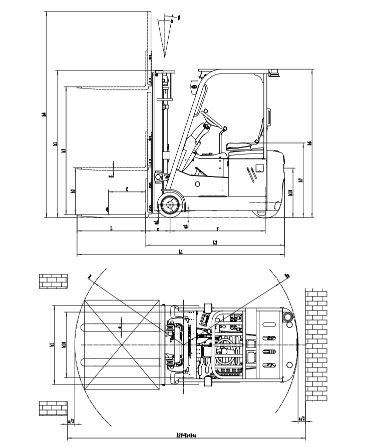

Even more astonishing? DC forklifts only required 24% of the space necessary to turn about. This meant that they could reorganize their warehouse for higher-density storage and thus raise overall throughput by 18%, overnight! This was nothing short of a silent revolution.

The remmedy:

Why Should DC Motor Forklifts Be Used in Office Logistics?

So why is the DC motor forklift for machine processing and office supply operations so unique? Unlike AC motor Fuji HEAVY Industries, DC motor technology has active torque control. This is important when transporting fragile things like laser printers or shredder mechanisms that can’t stand sudden jolts.

Shrinking To Fit

DC drivetrain designs are smaller in size than their AC counterpart. In the compact logistic centers typical of office supply chains, this yields immediate savings on space and thus cost reductions:

Quieter on the Job

Reducing noise in the logistics environment benefits not only the workers, but everyone higher up as well. So when you move toner cartridges or ergonomic chairs by day, traffic management becomes easier for night shift crews below (and there’s less chance that an accident might happen due to some unexpected noise).

Demonstrably Green

With B2B customers more and more interested in discussing ESG performance (Environmental, Social and Governance) as a component of their purchase decisions, a distributed control system offers a straightforward route to greening your entire logistics chain. This in turn strengthens your sales pitch.

I’ll be honest with you If your office supply warehouse still uses propane or AC forklifts, that madeirt record store guy down the road may already have outsold our company!

The SEO Question Answered: “Are Improved Motor Forklifts Worth The Cost?”

We often get asked this. Let’s answer it directly.

If you are handling large quantities of office supplies, in particular those that are high-frequency consumables like file cabinets, document shredders, or printer and copier toner cartridges… the answer will nearly always be “yes.”

One quick calculation of how these numbers could be changed over a span of 5 years (using SEMRush and 2023 industry data):

Cost FactorPropane ForkliftAC Motor ForkliftDC Motor ForkliftAvg. Annual Energy Cost$4,500$3,200$2,100Frequency of MaintenanceHighModerateLowLifespan (Years)71012+Avg. Noise Level90 dB75 dB62 dBCarbon EmissionsHighMediumLow

The secret to the DC motor forklift’s success lies in its approach as an operational strategy that manages to masquerade as something else altogether.

Market Trends: Where Are Things Headed?

According to Grand View Research (2024), the global electric forklift market will grow at 13.2 percent CAGR through 2030.Concerning this, DC-motor forklifts are one of the leading trends in growth for mid-size to smallish distribution facilities and are beginning to be used widely as office equipment and in retail outlets.

Heavy hitters like Office Depot and Staples have already started to totally overhaul their local distribution centers with DC forklifts, citing reduced energy consumption and the smoother guidance system operation that results.

Having already begun retrofitting their regional distribution hubs with DC forklifts, big-box brands like Staples and Office Depot hand some of the credit to reduced energy use and smoother Automated Guidance System (AGS) integration.

It is not just a shift. In fact, it is a strategic recalibration of how office equipment moves through the supply chain.

Step-by-Step: How to Transition Your Fleet to DC Motor Forklifts Without Disturbing Operations

The change is really not something that must be overwhelming. In fact, with a staggered roll-out a lot of operations enjoy ROI within 12-18 months.

Step 1: Audit Your Fleet

Start by gathering performance data from your current forklifts: energy usage, maintenance frequency, uptime hours and operating decibel levels. This baseline will enable you to identify the weakest links.

Step 2: Choose Pilot Locations

Select a high-traffic area like your toner or shredder storage aisles to run a controlled test with 1-2 DC motor forklifts. See how they perform compared to the existing legacy vehicles.

Step 3: Train Your Operators

Even though DC motor forklift trucks are usually more intuitive, operator training ensures that you maximize the full capabilities of torque control and braking precision. Many suppliers have complimentary hands-on modules for this task.

Step 4: Measure & Review

Use telemetry data to assess changes in people flow efficiency, maintenance costs, and decibel levels. Let data—not hunch—inform your investment decision.

Furniture Distribution Real-World Application: The Office Equipment 14% More Efficient Warehouse

In a 2023 study shared by Logistics Equipment Weekly, an East Coast office furniture distributor replaced five propane forklifts with three DC forklifts. The result?

Warehouse Noise dropped from 82 dB to 58 dB–enough for operators to no longer wear ear protection daily!

Space Efficiency increased due to the truck’s tighter turning radius–yielding an extra 2,200 square feet at which furniture can stand.

Questions for agencies with medical year-off troubles: Are you experiencing a real bottom-line loss, or just some mild pain in the wallet? Are the costs of lost employees worth investing in ergonomic changes? Does better forklift performance justify productivity sacrifices? The survey shows that after turning to electric forklifts, the number of employees for each personnel cost grew by 12%. This directly leads to improved ergonomic controls and reduced physical strain. “We are not just changing forklifts,” said General Manager Zhang. “We’re changing how our team and wharehouse coexist too.” The Costs You’re Not Paying for a Moment, but Will One Day Pay Sometimes the cost that you ignore the most is your biggest.ACCOUNT. DC motor forklift adopters avoid these:Increasing HVAC bills because heat-heavy IC forklifts drive it upThe ESG-reporting company’s exposure to carbon taxpenalty fines for OSHA noise violationsThe loss of contracts due to bad sustainability scores on RFPsAt an office logistics magazine, every unnecessary sound, Kilowatt or unforeseen repair is leaking costs. Intelligent Integration into Office Supply Chain Your forklift’s not living in an isolated system: it interacts with your racks, your staffpeople, and your IT systems. New-style DC motor forklifts even supportLShr-CH:Inventory Management Systems (IMS) These enable better automation and more accurate operation due to their precision.CustomPow Car Like System Thanks to DC braking, pick and place stations in dynamic fulfillment zones can stop more accurately.Mixed Environment: Because of its quiet operation (while still powerful), dcmotor forklifts can coexist with office assembly lines or light test platforms.Internal and external here we Go for Development To assist with the transition, we suggest linking internally to the following:Office Equipment “Warehouse Layout Optimization”Logistics: “Controlling Noise in Warehousing”Sustainable B2B Metodo Externo LogisticaTraffic includesS E Fugue Alliance: OS H Forkliff Noise StandardsGrand View Research: Electric Forklift Market (Thailand:DC motor erection PISA)Energy.gov on DC Motor Efficiency Conclusion: Boxes Are Not Lifted Alone—Margins Are Too If demineralization for a dc motor is just another device choice to you, you are just as wrong. Right now, it is a strategy of energy conservation, workplace safety, work efficiency and lasting client maintenance on whole different plants that previouly have counted on then operating rocks to cushion themselves off those points into oblivion. The crop’s been in the bin.

Knowing what’s really at stake tomorrow, how will you act differently?