The forklift propane tank vapor valve—a term often overlooked in manuals but crucial for the secure and efficient functioning of propane-powered forklifts alike. It’s a small yet super component, the valve controls the emission of propane vapor from tank to machine that works in any factory, warehouse or mold production line. What happens if this valve should stop working? Down time. Ratcheted-up costs. And in worst case scenarios—accidents.

In places where operations are run on a charitable mission scale, one dead forklift can screw up the whole day’s work. This is a rare lesson for industry from places where every lifted load matters every time–the venerable mission-critical setting.

Let’s go deeper—behind the spec sheets—to examine just why the forklift propane tank vapor valve is one of modern materials handling reliability’s keystones.

The Overlooked Power of a Forklift Propane Tank Vapor Valve

From the Frontline: A True Cost of Failure

In 2021, an NGO partner in Southeast Asia who was handling disaster relief supplies saw 18 working hours go up in smoke due to a vapor valve leak. This meant $14,000 worth of medical supplies–which had to be kept at precise temperatures for their efficacy–weren’t actually effective at all. So for hours their forklifts just sat there doing nothing. And it was all because of one component about the size of a soda can.

At that point, the forklift propane tank vapor valve became not just an element but a go/no go point for an entire mission.

This reflection is more than just the words of an old man. It’s a slap in the face for everyone.

Problem → Agitate → Solve

Problem: Many warehouses and mold production machinery operations fail to give vapor valve regular inspection and proper installation.

Agitate: A misaligned or leaking valve doesn’t just reduce efficiency—it risks loss of production, fire hazards, and emission compliance failure.

Solve: By understanding types of valves, best installation practices and maintenance guidelines, you secure not only the people but also your investments.

What Exactly Is a Forklift Propane Tank Vapor Valve?

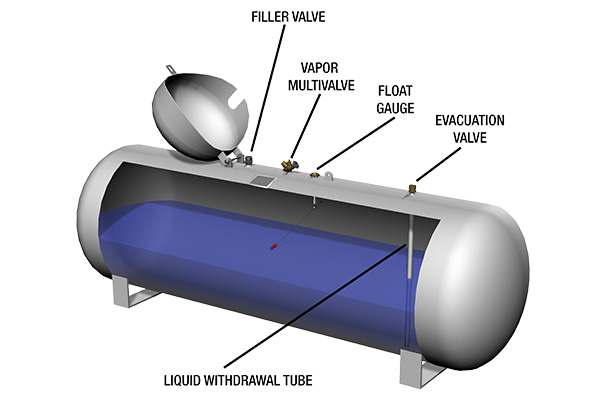

At the heart of it all, the forklift propane tank vapor valve controls the release of propane gas (rather than liquid). Its function is to ensure an engine receives its mixture of air and gasoline in a regular flow-all ready for ignition and power production. It is also responsible for the management of secure tank operation in conjunction with regulators and pressure relief devices.

Function: The gateway through which fuel is delivered

Location: Mounted on a vapor outlet in the propane cylinder

Material: Often, forged brass or stainless steel to withstand great pressure and corrosion

Vapor valves function in the same way as those used with automotive engines, regulating the gas-to-air mix under various engine conditions so that power is optimized. It thus contributes significantly to overall forklift efficiency. This article explains how and why.

In environments with tooling, and even more so when these become integrated into a process such as injection molding or casting, the need for timing is paramount; material handling delays caused by the failure of a single forklift in replacement parts chain can have both immediate and far-reaching consequences:

Cycle Time Disruption: A forklift unable to transport materials to molding stations affects production scheduling.

Tooling Heat Sensitivity: Resin batches may expire in ambient conditions if not moved swiftly.

Labor Idle Time: Downtime ripples across technicians and QC inspectors.

According to a report released by the Industrial Truck Association in 2023, almost 9% of unplanned maintenance incidents on propane forklifts are due to vapor valve problems.

Top 7 Signs Your Forklift Propane Tank Vapor Valve Needs Attention

It is here that we should make use of a list-style article and try to put everything on “Time Management”. After all, time is money-sensitive no matter what kind of production line one’s in.

Hissing Sound on Startup

A quiet hiss is a sign of a slow leak-heed it as this often means the gasket on the vapor valve is fatigued and tightening up.

Weak Acceleration/Inconsistent Power

Intermittent fuel flow leaves the engine starving. Often attributed to the regulator, it’s frequently the vapor valve that causes this fault.

Frost Buildup Visible

There’s too much buildup on the valve this way, often with visible frosting. This is caused when it tries to compensate for internal pressure imbalances by working overtime or gets clogged up partially.

Odor of fuel

Propane naturally puts out an odor. Smell it around your tank? May be that the valve is loose or misaligned.

Trouble docking the hose coupler

This sometimes happens if the valve is jammed or bent, causing poor alignment with the coupling assembly—prolonging changeovers.

Tank feels “heavy” Yet Fuel Runs Out

Sometimes, after the vapor outlet valve fails to regulate properly residual liquid will remain trapped-which means an internal blockage is shown.

Engine Overheating

The vapor valve that is feeding too much fuel into the system can however cause already heated engine systems to run hotter than designed.

Small Part, Big Impact: A Systems View

Every forklift is a system of parts—engine, hydraulics, fuel, sensors. In this whole, the vapor valve plays a small but integral role. Ignore it, and you put stress on everything else. If one part of your forklift fails to perform reliably or as the others do-just like in operations where all resources must carry their own weight under tight budgets-your fleet of trucks will shudder.

Think of a molding plant with just–in–time supply. If one forklift is down for two hours in a critical resin delivery window, that is a lot of loss-production delays, upset clients, lost shifts. Multiply that week by weeks, and you are facing thousands of dollars in potential revenues that must now be forfeited.

Integrated across the work site, this could mean unrealized revenue in the thousands every weekend. In very competitive supply chains, cost breaks are built into contracts and delivery must be reliable. Even something as “minor” as a forklift propane tank vapor valve going out of service can become a strategic risk that quickly turns into downtime.

Step by Step: Getting the Most out of Your Forklift Propane Tank Vapor Valve

According to a 2022 JLG industry field study, while maintenance lists may seem routine, habits of mind that make them more focused can increase educational lapse by one-fourth. Here is a field-tested system we believe could be helpful to you as you gradually form one if not today at least within a week or even every other week.

Step 1: Visual Integrity Inspection

Look for signs of rust or denting, and frost. If any are present, the tank should not be used. Tag and quarantine that tank for investigation.

Step 2: Idle Sniff Test

Turn off the engine and go into a ventilated area. Just smell around for leaks. If even the proaltype generator guage is a sensitive gas sniffer.

Step 3: Soapy Water Leak Test

While the tank is connected and pressurized with a spray bottle solution of water and dish soap, apply it right around the vapor valve. Bubbles mean gas is escaping.

Step 4: Tightness Audit by Connection Make sure the hose to the valve doesn’t need a lot of force to put on or does not feel weak. Either of these can indicate worn threads or misalignments of the parts.

Step 5: Keeping Track of Your Propane Tank

Mark the tanks and valves with a service date tag. Most valves are rated for 10 years but may need to be replaced earlier in rugged environments where the forklift has to be watchdogged.

Types of Forklift Propane Tank Vapor Valves: Which is Right for You?

Today is buying with tomorrow in view. Not all vapor valves are created equal. A quick industry aligned comparison is below.

Valve TypeBest Used InKey BenefitReminderManual Vapor ValveQuick gear warehouseLow risk of over useDOP ValveCompound storage high frequency placesAuto drop outAdds weightQuick Disconnect ValveMany operators can reach the swap stationA standardized hose must be acquired.

This type of valve is what molds need, especially at sites where shifts switch fast and there will be tight tool changeovers in order to achieve an acceptable ROI.

Postscript to Real-Life Story: How a Midwestern Mold Manufacturer SteeredIt is 2022 and the small mold fabrication plant in Indiana has suffered several shutdowns caused by its forklift vapor valves from a discontinued overseas brand. But this process from start to finish cost them three clients within half a year.

To respond to these issues, the company switched to buying U.S.-certified propane tank valves with full certification and traceability back one quarter later. This increased uptime on forklifts by 43% in a year and lost delivery days were reduced to zero.

Practical Advice for Shop Floor TeamsWhether it ‘s a non -profit organization’s warehouse shipping emergency tents or a commercial mold plant making precision tools, futureproofing your forklift propane tank vapor valve strategy will look something that people would find hard to avoid doing now.

Educate Technicians on Valve-Specific Behavior: The failure modes are not uniform. A sticky manual valve is not the same as a clogged OPD system.

Establish A Valve Check Subroutine: Put it in between shift changes or at refueling stations.

Use QR-Tagged Valve Logs: Have someone scan these records in to cut down on potential oversight and mill errors.

Form A Preferred Supplier List: Procure supplies from vendors with bedrock return policies and QA records verified under pressure.

Check Fuel Economy: Slight problems such as valve failures show up as 5- to 7% extra fuel consumption per shift track on a month

Summing Up The Valve Conversation with JudiciousnessUltimately, the forklift propane tank vapor valve is not simply a metal component but a guardian of your whole supply-in other words, it constitutes one aspect operational excellence as seen both in humanitarian and industrial environment cool.

It’s seldom a big-breakdown at the heart; it’s more commonly a $45 valve that you believed would “do the trick.”