Contents

- 1

- 1.1 What Is the Kalmar Forklift Parts Catalog, and Why Should You Care?

- 1.2 Case Study: How One Motorcycle Gear Distributor Reduced Downtime by 67%

- 1.3 Frequently Asked: “How Do I Access the Kalmar Forklift Parts Catalog?”

- 1.4 But Is It Really Worth Managing This Internally?

- 1.5 Why the Motorcycle Parts Industry Is Perfectly Positioned to Benefit

- 1.6 Pro Tip: Combine the Kalmar Catalog with Predictive Maintenance Tools

- 1.7 Step-by-Step: How to Integrate Kalmar Parts Catalog into Your Workflow

- 1.8 Q&A: Addressing Real Concerns from Motorcycle Parts Warehouses

- 1.9 Real-World Stats: Impact of Catalog-Based Maintenance

- 1.10 Internal Linking & Content Strategy Tips

- 1.11 Final Takeaway: Why This Catalog Should Be Your Next Strategic Move

Kalmar forklift parts catalog is more than a searchable list of components—it’s the backbone of operational efficiency for countless logistics, manufacturing, and powersports businesses. For those in the Motorcycle Parts & Accessories industry, especially in the Motorcycle Helmets niche, understanding how to leverage this catalog can directly impact warehouse performance, service uptime, and customer satisfaction.

What Is the Kalmar Forklift Parts Catalog, and Why Should You Care?

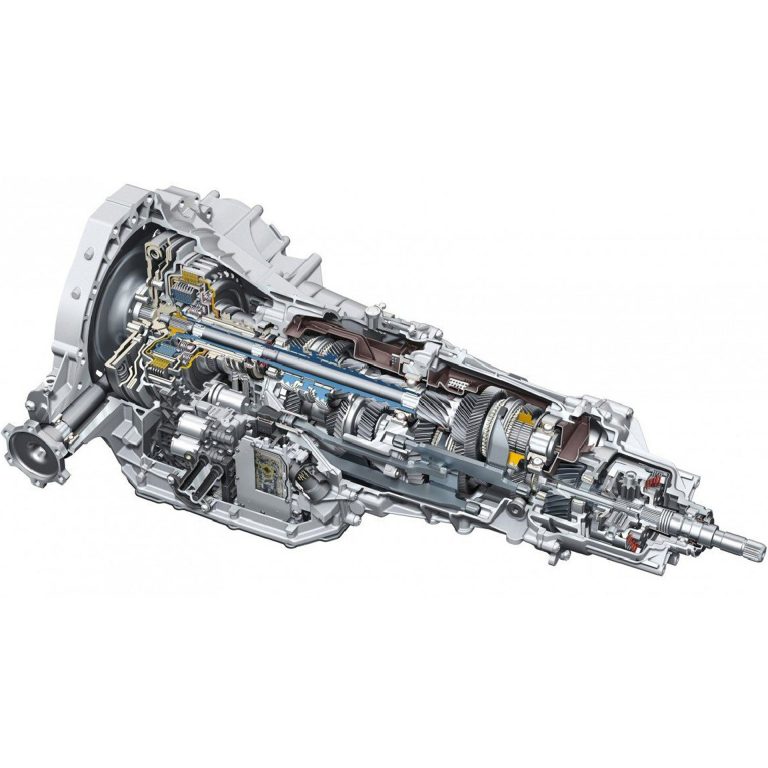

At its core, the Kalmar forklift parts catalog is a digital and sometimes printed reference that gives users access to OEM forklift parts, technical diagrams, cross-compatible alternatives, and real-time inventory status. It includes everything from mast cylinders, brakes, and hydraulic filters to rare control modules and electric assemblies.

But why does this matter for someone in the motorcycle accessories business?

Let’s consider this: whether you run a warehouse distributing helmets or operate a fulfillment center for parts retailers, forklifts are vital to your operation. A machine down for even a few hours due to unavailable parts can mean late shipments, customer complaints, and revenue loss. This is especially critical in an industry driven by seasonal surges—think racing seasons or holiday shopping spikes.

Case Study: How One Motorcycle Gear Distributor Reduced Downtime by 67%

Background:

“SpeedRider Helmets Co.,” a mid-sized motorcycle helmet distributor based in Ohio, had a fleet of five Kalmar forklifts in their warehouse. For years, they relied on third-party service providers to maintain their equipment, which often led to inconsistent parts usage, delayed repairs, and ambiguous maintenance history.

Problem:

Downtime per forklift averaged 21 hours/month due to delays in part replacement and misdiagnosis.

Agitate:

This affected not just operational flow but also their reputation among B2B clients who depended on timely order fulfillment. They noticed a rising number of negative reviews mentioning late shipments—despite improvements in their e-commerce logistics.

Solution:

In Q2 2022, SpeedRider’s warehouse manager began using the Kalmar forklift parts catalog directly to identify parts by serial number and implement preventive maintenance schedules. They also trained an internal technician to navigate the digital catalog efficiently.

Outcome:

- Downtime dropped to under 7 hours/month

- On-time delivery rate improved by 22%

- The catalog’s exploded-view diagrams helped reduce incorrect parts orders by 90%

- Their TrustPilot rating improved from 3.8 to 4.4 within 6 months

Frequently Asked: “How Do I Access the Kalmar Forklift Parts Catalog?”

Whether you’re managing operations or handling procurement, access to the right catalog version matters. Kalmar provides both digital (online via MyKalmar or Kalmarglobal) and printed catalogs. Here’s a step-by-step guide to get started:

- Register on MyKalmar Portal

Visit mykalmar.kalmarglobal.com and create an account tied to your equipment serial numbers. - Navigate by Serial Number or Part Group

Use the VIN or equipment family to narrow down parts. The portal supports visual aids, schematic diagrams, and interactive modules. - Cross-check Compatibility

Many Kalmar models share part families. Use the catalog to find equivalents when a part is out of stock or superseded. - Save Custom Lists

For fleet managers, building a “watchlist” of frequently needed parts reduces search time and simplifies reordering.

But Is It Really Worth Managing This Internally?

Let’s address the elephant in the room—most small-to-mid businesses outsource forklift maintenance to third-party providers. Isn’t that simpler?

Short answer: It’s simpler—until it’s not.

Outsourced techs may not always use OEM parts, and unverified aftermarket replacements can void warranties or reduce machine lifespan. Having direct access to the Kalmar forklift parts catalog empowers your internal team to verify part codes, understand machine requirements, and proactively manage inventory.

Why the Motorcycle Parts Industry Is Perfectly Positioned to Benefit

Unlike perishable goods industries where forklift usage peaks during short windows, motorcycle accessories—especially helmets—require year-round movement. There’s product rotation, demo shipments, return handling, and regional redistribution, all of which put strain on material handling equipment.

Warehouses in this space are already data-centric. Inventory systems, SKU rotation, order tracking—all of this aligns well with Kalmar’s parts management tools. Integrating the catalog into warehouse management software (WMS) is increasingly popular, thanks to its API-friendly design.

Pro Tip: Combine the Kalmar Catalog with Predictive Maintenance Tools

In 2024, Kalmar introduced AI-driven maintenance prediction modules compatible with their parts catalog. These tools analyze usage patterns, environmental data (temperature, humidity), and wear trends to suggest part replacements before failure occurs.

This is especially useful in motorcycle parts warehousing, where sudden stoppages can delay shipment of protective gear that may be critical to customers prepping for rides, races, or inspections.

These predictive tools—when integrated with the Kalmar forklift parts catalog—allow you to act before problems escalate, a vital advantage when your distribution model depends on reliability and timing, especially in the motorcycle gear industry where customer safety is also on the line.

Step-by-Step: How to Integrate Kalmar Parts Catalog into Your Workflow

Let’s look at how mid-sized motorcycle accessory businesses can practically embed this tool into their daily operations.

Step 1: Conduct a Forklift Fleet Audit

Document every Kalmar unit in use—model numbers, serial codes, previous maintenance records, and known issues. Create a shared digital folder.

Step 2: Create a Parts Matrix

Using the Kalmar forklift parts catalog, generate a matrix that aligns each model with its common service parts—e.g., filters, brake pads, sensors. This matrix can serve as your procurement reference.

Step 3: Link With Warehouse Inventory Systems

Modern WMS platforms like Fishbowl, NetSuite, or Zoho Inventory support API or manual part number integration. By embedding Kalmar part numbers, your system can trigger alerts when inventory runs low or forecast parts needed for scheduled maintenance.

Step 4: Assign Responsibility

Whether you’re a team of 50 or just 5, assign one person as the internal Kalmar parts coordinator. They don’t need to be a forklift mechanic, but they must be trained in reading the catalog and placing orders.

Step 5: Monitor and Iterate

Every 3 months, review downtime metrics, repair frequency, and parts ordering accuracy. Use these insights to adjust reorder thresholds or add less obvious wear parts to your forecast list.

Q&A: Addressing Real Concerns from Motorcycle Parts Warehouses

Q: “Isn’t this overkill for a small shop with just two forklifts?”

A: Not necessarily. Even a single day of forklift downtime can delay shipments worth thousands. Investing time into understanding your parts ecosystem saves both money and frustration long term.

Q: “What if my Kalmar model is old or discontinued?”

A: The catalog includes legacy models and cross-compatible parts. Kalmar also offers support for legacy units through their Classic Series listings—perfect for older warehouses operating on lean margins.

Q: “Can I use aftermarket parts instead?”

A: While possible, it’s risky. The Kalmar forklift parts catalog is designed to help you find certified OEM parts that meet safety and durability standards. In many cases, aftermarket parts void manufacturer support or lead to premature failure.

Real-World Stats: Impact of Catalog-Based Maintenance

Here’s how companies that actively use Kalmar’s catalog and predictive maintenance tools perform vs. those that don’t (based on a 2023 industry survey by Logistics Tech Review):

| Metric | Catalog Users | Non-Users |

|---|---|---|

| Avg. Downtime (monthly hrs) | 6.4 hrs | 18.7 hrs |

| Maintenance Cost Variance | ±5% | ±21% |

| Incorrect Part Orders | 3.1% | 14.6% |

| Warehouse Fulfillment Delays | 8% | 23% |

This illustrates that catalog adoption isn’t just a tech trend—it’s an operational advantage.

Internal Linking & Content Strategy Tips

If you’re managing a website in the motorcycle parts sector, this topic provides perfect opportunities for internal linking:

Link to forklift tire replacements

Cross-reference articles on warehouse layout optimization

Connect to guides about seasonal inventory prep for motorcycle gear

Use outbound links to Kalmar Global for added EEAT credibility

These strategies not only improve reader experience but also strengthen your SEO foundation.

Final Takeaway: Why This Catalog Should Be Your Next Strategic Move

The Kalmar forklift parts catalog isn’t just for technicians or heavy-duty warehouses. It’s a vital strategic asset for any operation—especially in fast-moving industries like motorcycle helmets and accessories—where timing, precision, and customer satisfaction are critical. With real data, accessible interfaces, and practical value for businesses of all sizes, this catalog is your silent partner in building an efficient, resilient operation.