For companies dealing with bathroom furniture, this component which might seem rather unimportant is reshaping the way things are prepared, stored and shipped. This one single component in material handling equipment, though easily overlooked, directly influences warehouse efficiency, the success of last-mile delivery and – in some cases – even production schedules. Yet many involved in the bathroom furniture industry only begin to realise this when it is already too late- -for instance, when supply chain backlogs cause delayed orders or their wooden-steeringsystems will not allow a forklift to navigate tight aisleways in a warehouse.

Specifically, imagine a medium-sized German contract manufacturer of bathroom vanities. It recently expanded its assortment to include modular wall units. This required completely revamping logistics inside the company: new rack systems,more narrow pallet configurations (in order to fit into and beside all this other equipment) and processing of the finishing phase. The firm did not realize that its current forklift fleet would be unable to handle these changes. The reason? Steering engines not developed for precise control. Result: damage to goods in transit isincreased, shipping is delayed and the return rate. is much higher.

Issue: The Small and Large Losses Of Overlooking The Forklift Steering Motor Market

In reality, for bathroom furniture brands —especially those with a large number of SKUs or items that are customisable or must be combined in any number of ways, internal logistics is a hidden cost center indeed. You might put your money into sustainable MDF, design an ergonomic drawer system or with innovation such as mirrors made to try theories of perceptive physic yet if materials can’t move properly within your warehouses then shortcomings will devour away at profits. Here’s where the forklift steering motor market becomes pertinent.

For DCs (Distribution Centers) in the region where bathroom furniture is produced, farming or plantations are mostly the industries. Most of these companies operate very large numbers of these kinds of machines – thousands to tens of thousands at any one time. In order to steer accurately through dense packed inventories without damaging finishes like lacquered plywood,VMC focused especially on driver behaviour and turned the steering wheel into a platform by itself with a unit that allowed reversal of direction. Steering motors that didn’t perform adequately produced:

A large turning circle, poor manoeuvrability in tight aisles

Consequence of operators getting tired due to imprecise steeringachinery But you can act now: take an active part in industry standard-setting bodies today and help improve conditions for future generations at factories everywhere!

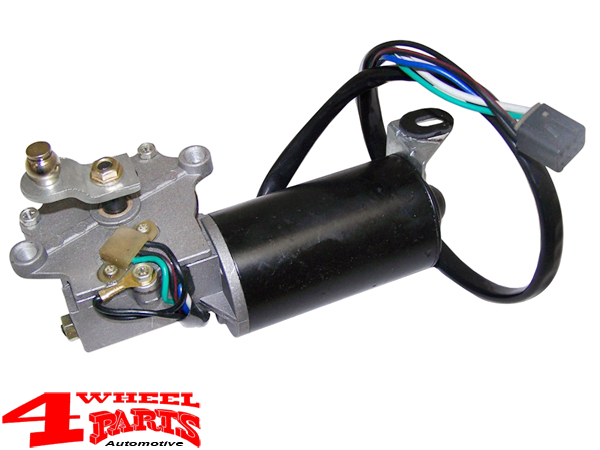

Excessive wearing and breakages will mean more periods of inactivity Greater energy intake from inefficient torque outputDisreputable variables in a market where speed and quality deliver return businessThe Present: Industry Shifts Change The Game–And Now You’re Trying to Catch UpGlobal wrinkles have set off a massive change in the direction of forklift steering motors business. So how can he resist a trend that no one can afford to miss? A McKinsey logistics study in 2023 reported that 65% of European warehouse operators have switched to electric forklifts and this figure is expected to reach 82% by 2026. This directly influences the demand for steering motors, especially brushless DC (BLDC) motors offering efficiency in energy saving, less noise and better torque control -an indispensable need when maneuvering forklift-borne glass or tile bathroom parts. But outdated motor systems or hybrid legacy units simply cannot be easily retrofitted into place. This results in many mid-sized manufacturers upgrading their motors trying to maintain compatibility with the new systems occurring around them, leading to added delays in expansion plans. 2. Supply Chain Localization & Just-in-Time Stress with container costs still 35% above pre-pandemic levels(as of Q1 2025), many bathroom furniture companies are localizing production. That means new regional warehouses, new fleets — and just new requirements on fork-lift steering motor nimbleness in smaller or reconfigured facilities. 3. Customization & SKU Proliferation Personalization trends in bathroom furniture–floating vanities, tech mirrors with integrated features, stone resin tops–produce more and more components on Morioka Kansho’s ley grams. That translates into increased picking frequency, Himalayan bin spacings, wasted sashimi peels. The old motors? Simply not up to the task.

Industry case on a typical landing will handle moment:

Rising warehouse accidents weren’t discovered until a leading Polish brand compliant to the integral method complained to the supplier in 2024 that isn’t as ordinary used under- sink cabinets. After some root cause analysis, they pinpointed the issue to is old-style steering motors that simply could not cope with new irregular ( “zigzag ” ) layout for storage. So they made good and just changed over to CAN-tf bus-type control, ibid all-energy-rationed motors. ROI inside 6 months.

What’s to be done: For Stakeholders in the Canadian Situation of the Bathroom Furniture Industry

If you make bathroom furniture and have yet to check out your warehouse mobility machinery, don’t miss this chance. Here’s how:

Part One: A Motor Use Review

Record current forklift steering motor specs (torque, rpm, voltage compatibility).

Find out the average width in your warehouse aisle as compared with what is necessary for a turn.

Record failure/downtime frequency data due to steering problems.

Part Two: Performance Gaps Defined by Chances in the Product Mix

High-gloss enamel surfaces? You must have limbs cradled softly and hand-twitch shock-absorbed steering.

Small stuff such as a piece of tap hardware (etc) in those parcels? Motor with stronger maneuverability desired.

Heavy goods (as with cast marble tops): You need big-torque steering motors.

Part Three: With the Best Leading Forklift Steering Motor Market Vendors in the Country to Talk To

Some well-known vendors in this department are:

ZAPI Group- makers of moduliafablenome blank, steer(v)bldc atairs with Iot features.

Curtis Instruments/ offering a kind of ago that could notprofile–literally- contain torage control.

Delta-Q Technologies– tailor-made motors for the logistics industry indoors with ergonomic lifting.

Tip for you: Go ask about integrated predicted maintenance. Not only do motors with bult-in sensors lower the risk of unintended problems and let technicians working on main* tenance before they arc hanced, they also make it ridge for personnel to know in advance whe`n they’re working too hard!”

built-in feedback and outside sensors can smartly forecast where its fail point are, meaning a bathroom furniture maker can take thousands of dollars off wasted overtime (or returned merchandise).Moving delicate goods —such as a porcelain washbasins and vanity mirror cabinets—around doesn’t really much depend on technical precision alone; it ‘s got to do with the bottom line.Entertainment amongst friends.

Market Trend Analysis: 2025 Goodbye, Forklift Steering Motor Market.Comparing the forklift steering motor market to a giant confluence of three streams, steer clear.Each stream itself makes its course.

A. Diversification of Needs Beyond Traditional Logistics Warehouses

While storage remains the largest segment, rising demand from wider markets like in-showroom tote carts, vertical shelf lifts, modular floors is fuelling secondary growth. The bathroom furniture seller-cum end-mile distributer— especially in upmarket show case — often looks for quiet, compact and precise steering systems (sometimes having served as mobile up and down on floors via elevators).In this case, boutique brands from Italy specializing in hand-made marble sinks are asking for custom steering systems in their narrow, heritage-status storehouses. This has carved out a fat little niche for the forklift steering motor market—salable only to agile suppliers.

B. Tech Leap: Smart Steering, AI Calibration, and Energy RecoveryStihl power saws.

By 2025, the steering motor is no longer the same old passive torque beast. The newest generation embodies:

Adaptive load compensation methods (that don’t shatter frail artifacts when torsional shock arrives)

Energy recovery modules (to conserve motor power in a full night’s work)

Bluetooth diagnostic tools (in real life it’s open sixteen that relates with the motor)And these arenot just technical gadgetry. For bathroom furniture producers attended by AGVs (Automated Guided Vehicles) or planned by plans to bring in AMRs (Autonomous Mobile Robots) the kind of steering motor you have now and in the future could be decisive factors in determining automatic policy.

An industrial top player in Scandinavia introduced AI-tuned motors into its automated warehouse and reported a 12.8% decrease within six months in handle-with-care damage. That leads to much less warranty claims–which, for built-to-order bathroom storage units, can cut margins by as much as 20%.

C. Sourcing Mode: From Global Specialization to Regional Specialization

The sourcing landscape is also changing. In response to geo-political instability and tariff uncertainty, much of the forklift steering motor market has shifted to regional centers:

Germany and Czechia are emerging as centers for precision-engineered motors

Shandong and Guangdong provinces in China remain the dominant locations for volume manufacturing of standard units

In North America, manufacturing is returning to the vicinity of the customers, and particularly with an emphasis on integrating motor controllers

Bathroom furniture exporters who plan to regionalize their logistics operations will need to connect with locally based steering motor suppliers because this is what is expected not just for reliability but also so their technical service can be agile.

Action plan: What bathroom furniture professionals should do next

To make sure you’re not falling behind in logistics abilities, follow these actionable steps:

Involve procurement in logistics planning: In many cases, procurement teams are in their own silo and separate from warehouse ops. However, if you’re buying new shelving units or adjusting box dimensions, get them involved in motor spec discussions early.

Run a forklift fitment simulation: Use digital twins or CAD-based layout simulations to see how different steering motors perform when interfaced with your particular warehouse config. This will prevent costly trial-and-error purchases.

Negotiate service-level agreements: If you’re dealing with custom bathroom furniture (think detachable drawers that shut quietly or concealed LED lighting), steering reliability is critical. Work with motor vendors to include service agreements guaranteeing uptimes and fastcut.

As some newly emerging EU plans come into play, stringent energy efficiency ratings for industrial electric motors could become obligatory by as late as 2025. This advanced warning can work cooking your brand – particularly if your bathroom furniture is sold as green or sustainably farmed.

The combination of both of these is internally consistent and so aligning your looks excellent material somewhere nearby as our superior supplier—which, just happens to have been internalized. Welcome aboard with no sign up required! Through this careful positioning, you not only improve warehouse operations but also assure future sustainability for your entire value chain. In the high-stakes game of bathroom furniture where design meets purpose, precision logistics driven by forklift steering motors can serve as a revolutionary advantage in this war between brands.