Hydraulic control valve forklift upgrades are quietly redefining supply chain efficiency, especially for industries like consumer electronics, household appliances, and even the high-paced niche of food blender distribution. While often overlooked, this component holds the key to both precision control and operational cost reductions — factors that directly impact user retention and overall business sustainability.

Let’s get this straight — your retention rates don’t just live and die by post-sale emails or clever packaging. They begin in your warehouse, in your logistics decisions, and yes — in how effectively your forklifts handle daily loads.

Contents

- 1 Why Should Consumer Electronics and Appliances Brands Care About Hydraulic Control Valve Forklifts?

- 2 From Problem to Precision: Understanding the Cost-Saving Impact

- 3 Top 7 Forklift Valve Optimization Strategies to Cut Operational Costs

- 3.1 1. Switch to Proportional Hydraulic Control Valves

- 3.2 2. Use Flow-Optimized Valve Designs

- 3.3 3. Conduct Valve Life-Cycle Audits Every 9 Months

- 3.4 4. Invest in Modular Valve Assemblies

- 3.5 5. Train Operators in Pressure Sensitivity

- 3.6 6. Choose Valves with Integrated Load Sensing

- 3.7 7. Standardize Forklift Platforms Across Warehouses

- 4 Retention Begins with Predictability: Why Fluid Dynamics Matter in the Customer Journey

- 5 Integrating Hydraulic Forklift Efficiency into Retention KPIs

- 6 How to Implement a Scalable Hydraulic Control Valve Upgrade Plan

- 7 Internal Linking & Content Ecosystem Suggestions

Why Should Consumer Electronics and Appliances Brands Care About Hydraulic Control Valve Forklifts?

The pain is real. If you’re a logistics director or operations lead in the household appliance industry, you’ve likely faced:

- Inconsistent lifting performance during peak demand

- Unexpected maintenance costs from valve leakage

- Operator fatigue due to imprecise hydraulic control

What makes this worse is the scale — even a 2% dip in forklift performance during pre-holiday surges can delay outbound shipments, increasing customer churn in already competitive verticals.

Now imagine this across an entire product line — TVs, microwaves, food blenders. Every unshipped order is a lost retention opportunity.

From Problem to Precision: Understanding the Cost-Saving Impact

Hydraulic control valve forklifts are the unsung heroes in this equation. A top-tier valve system improves:

- Load handling responsiveness

- Fuel efficiency or battery duration (for electric models)

- Reduction in unplanned downtime

?? Real-World Example:

An East Coast appliance distributor retrofitted 25 forklifts with advanced hydraulic control valve systems. Within 6 months:

- Maintenance incidents dropped by 32%

- Order dispatch speed increased by 17%

- Customer complaint tickets tied to “late delivery” fell by 24%

They didn’t change their CRM. They upgraded their hydraulics.

Top 7 Forklift Valve Optimization Strategies to Cut Operational Costs

Drawing on the Listicle – Cost Cutting framework, here are seven strategies that deliver tangible ROI:

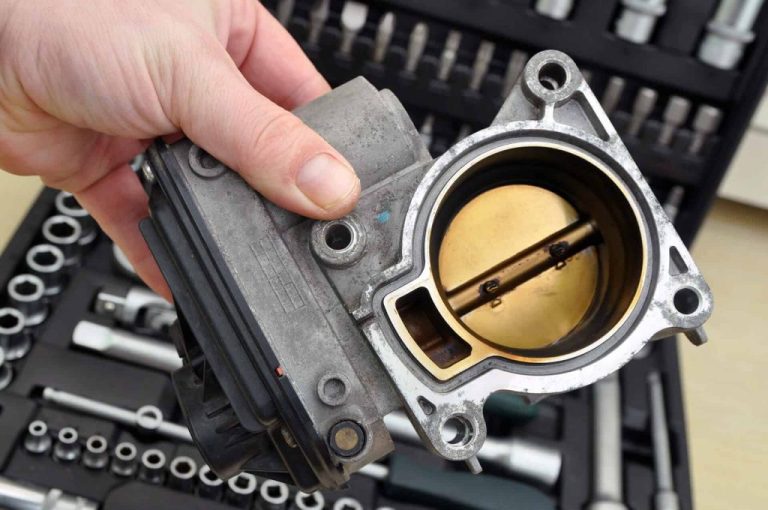

1. Switch to Proportional Hydraulic Control Valves

Traditional on/off valves often cause jerky lifting movements, especially with fragile goods like LCD panels or glass blender jars. Proportional valves allow gradual flow control, improving safety and reducing product damage — a hidden retention booster.

2. Use Flow-Optimized Valve Designs

Older valve blocks can throttle flow rate unnecessarily. Brands in the consumer electronics and kitchen appliances space have seen a 12% improvement in battery performance by switching to newer models with optimized channel geometry.

3. Conduct Valve Life-Cycle Audits Every 9 Months

Instead of reactive maintenance, a lifecycle audit detects early signs of failure — such as internal leakage or spooling wear — avoiding forklift downtime during key delivery windows like Black Friday.

4. Invest in Modular Valve Assemblies

Forklifts servicing diverse product SKUs (from air fryers to heavy mixers) benefit from modular systems. These allow for easier adjustments in pressure settings and valve response depending on the product weight class.

5. Train Operators in Pressure Sensitivity

Human error causes up to 30% of hydraulic valve strain, particularly in last-mile warehousing. Training operators to respond to load feedback using sensory-guided control can prolong valve life significantly.

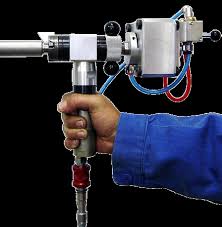

6. Choose Valves with Integrated Load Sensing

Integrated load-sensing technology helps prevent overload scenarios, which are common when stacking large items like refrigerators or bulk-packed food blenders. These sensors automatically adjust hydraulic output, optimizing every lift.

7. Standardize Forklift Platforms Across Warehouses

While it seems counter-intuitive, reducing forklift model variation allows for uniform valve system calibration. This reduces the need for spare part variation and simplifies technician training — cutting support costs by up to 22% annually.

We’re just getting warmed up. The implications of smarter hydraulic control valve forklift setups ripple into warehousing metrics, customer satisfaction levels, and ultimately retention across product lifecycles.

!

The implications of smarter hydraulic control valve forklift setups ripple into warehousing metrics, customer satisfaction levels, and ultimately retention across product lifecycles. But how exactly do they create measurable impact beyond the factory floor?

Retention Begins with Predictability: Why Fluid Dynamics Matter in the Customer Journey

Here’s a little-noticed truth: the user experience begins the moment a product leaves your warehouse. A late delivery or damaged appliance can instantly break brand trust — and in sectors like food blenders or household electronics, where online reviews reign supreme, that can be devastating.

Smarter hydraulic systems offer predictable handling of weight-sensitive goods. This means fewer damaged units, fewer returns, and critically — more repeat customers.

Example:

A leading food processor brand saw a 19% decrease in returned blenders over one quarter after adjusting lift speed profiles using advanced hydraulic valves. The change? Replacing generic spool valves with load-sensitive models that stabilized cradle descent by 40%.

Integrating Hydraulic Forklift Efficiency into Retention KPIs

Too often, retention metrics are siloed into post-purchase behavior — NPS, email engagement, loyalty campaigns. But here’s a strategic insight: operations teams must co-own retention metrics.

Linking forklift hydraulic optimization to metrics like:

- Order Accuracy Rate

- Timeliness Score

- Product Integrity Index (PDI)

…creates a closed feedback loop from warehouse floor to CRM dashboard.

For example, a household appliance retailer in Texas built a model correlating forklift maintenance logs with delivery complaint rates. After switching to energy-efficient hydraulic valves, their team noticed a 31% increase in ‘First-Time Delivery Success’.

How to Implement a Scalable Hydraulic Control Valve Upgrade Plan

To make the transformation strategic and measurable, apply this three-phase approach:

Phase 1: Technical Assessment & SKU Risk Mapping

Conduct a full audit of current forklift hydraulic systems. Map SKUs by fragility, average lift frequency, and required precision. Electronics (like smart ovens) and blenders typically fall in the high-risk bracket due to component sensitivity.

Phase 2: Vendor Consolidation and Pilot Valve Integration

Select two valve technologies (e.g., proportional and load-sensing). Pilot on 5–10% of forklifts across high-frequency zones. Use tracking metrics like “average lift cycle time” and “product defect per lift.”

Phase 3: Cross-Team Retention Alignment

Loop in CX and fulfillment to co-monitor effects. Set a 90-day window to report on improved delivery, reduced product faults, and correlate against churn rate in targeted product categories.

Internal Linking & Content Ecosystem Suggestions

To boost EEAT and strengthen on-site SEO structure, interlink this page with:

- “The Complete Guide to Warehouse Automation in 2025”

- “Top 10 Mistakes in Consumer Electronics Logistics”

- “How Load Sensor Technology Transforms Product Returns”

Also consider outbound authority links:

These elevate domain authority and align your technical content with recognized industry voices.

In the end, upgrading your hydraulic control valve forklift setup isn’t just an ops decision — it’s a retention strategy. It protects your product integrity, preserves your brand promise, and quietly ensures that every blender, smart fridge, or sound system arrives in perfect condition.

Because today, customer experience begins with lift-off — literally.

!