H10300637 DRT450 KALMAR 923976.0395 720 Water Temperature Sensor

the Water Temperature Sensor is a critical component that ensures the efficient operation and longevity of engines and industrial systems.

H10300637 DRT450 KALMAR 923976.0395 720 Water Temperature Sensor - Advanced Analysis

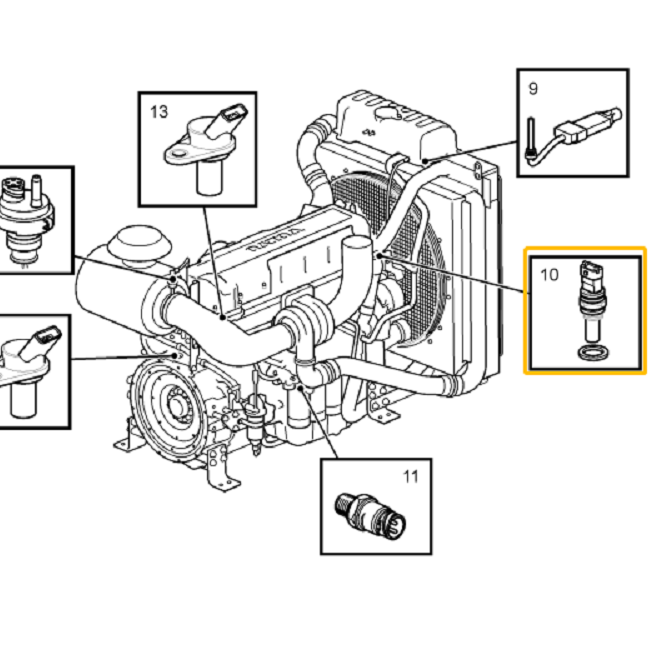

The Water Temperature Sensor is an essential component in automotive and industrial systems, designed to accurately measure the temperature of water or coolant circulating through an engine or machine. It plays a critical role in regulating engine performance, preventing overheating, and ensuring the efficient operation of the engine cooling system. The sensor continuously monitors the water temperature and sends real-time data to the engine control unit (ECU) or other monitoring systems, allowing for timely adjustments to maintain optimal operating temperatures.

In automotive applications, the Water Temperature Sensor is primarily used to monitor the coolant temperature in the engine’s radiator and cooling system. By providing precise temperature readings, the sensor ensures that the engine does not overheat, which could lead to engine damage or failure. The Water Temperature Sensor sends signals to the ECU, which can trigger the cooling fan or adjust the engine’s power output to lower the temperature. This helps prevent engine overheating, improving fuel efficiency and reducing the risk of costly repairs.

The Water Temperature Sensor is typically mounted within the engine cooling system, where it can directly measure the temperature of the coolant as it flows through the engine block. The sensor uses a thermistor or similar temperature-sensitive element to detect changes in the coolant temperature and send corresponding electrical signals to the vehicle’s ECU. This data is essential for optimizing engine performance by adjusting fuel injection, ignition timing, and other parameters based on the coolant’s temperature.

Beyond automotive use, the Water Temperature Sensor is also utilized in a wide range of industrial applications. In manufacturing, machinery, and HVAC systems, the sensor helps ensure that equipment operates within the correct temperature range, preventing overheating and maintaining system efficiency. In industrial cooling systems, the Water Temperature Sensor helps monitor the temperature of the water circulating through cooling towers, chillers, and industrial equipment, ensuring the system remains within safe operating limits. It is vital in preventing equipment damage, downtime, and energy waste, ensuring that systems run efficiently and safely.

One of the primary advantages of the Water Temperature Sensor is its ability to prevent engine or system damage caused by overheating. Without proper temperature regulation, engines and industrial machines are at risk of overheating, which can lead to irreversible damage to engine components, seals, and gaskets. The Water Temperature Sensor helps mitigate these risks by providing accurate, real-time feedback that allows operators to take preventive measures before the temperature rises to dangerous levels.

In modern vehicles, the Water Temperature Sensor is integrated with various vehicle control systems, such as the cooling fan control, climate control system, and cabin heater. By accurately monitoring the temperature of the coolant, the sensor helps maintain optimal cabin temperature for the driver and passengers while reducing energy consumption. The precise data provided by the sensor ensures that the cabin heater operates efficiently, adjusting the heating level based on the engine’s temperature and minimizing unnecessary fuel consumption.

The Water Temperature Sensor is engineered to operate reliably under extreme conditions. It is built to withstand high temperatures, pressure fluctuations, and exposure to chemicals or contaminants found in the engine or industrial environment. Made from durable materials such as stainless steel or corrosion-resistant alloys, the sensor is designed to deliver long-lasting, accurate temperature readings even in the harshest conditions. Its robust construction ensures that it maintains its functionality and accuracy over time, even with prolonged use.

Routine maintenance and proper installation of the Water Temperature Sensor are essential to ensuring that the sensor continues to provide accurate readings. Over time, wear and contamination can cause the sensor to lose accuracy, leading to incorrect temperature readings that can affect engine performance or system operation. Regular inspections and cleaning of the sensor can help maintain its performance, and replacing a faulty sensor promptly can prevent damage to the engine or machinery. Symptoms of a malfunctioning sensor include fluctuating or inaccurate temperature readings, failure to trigger the cooling system, or warning lights on the dashboard.

In conclusion, the Water Temperature Sensor is a critical component that ensures the efficient operation and longevity of engines and industrial systems. By providing accurate temperature readings, the sensor helps maintain optimal engine performance, prevents overheating, and protects critical components from damage. Whether used in automotive, industrial, or manufacturing applications, the Water Temperature Sensor is essential for maintaining safe operating conditions, improving fuel efficiency, and reducing maintenance costs. Proper maintenance and timely replacement of the sensor are necessary to ensure its continued reliability and effectiveness.

For more information regarding the regulations and standards related to the Water Temperature Sensor and other components, you can visit the official website of the Environmental Protection Agency (EPA) at https://www.epa.gov/.

1. Reliable water temperature sensor for engine cooling systems

2. Durable water temperature sensor for industrial machinery

3. High-performance water temperature sensor for automotive applications

4. Accurate water temperature sensor for preventing overheating

5. Long-lasting water temperature sensor for industrial and automotive use

Bulk Source H10300637 DRT450 KALMAR 923976.0395 720 Water Temperature Sensor

Direct Factory Pricing | OEM/ODM Customization | GRS Certified Materials