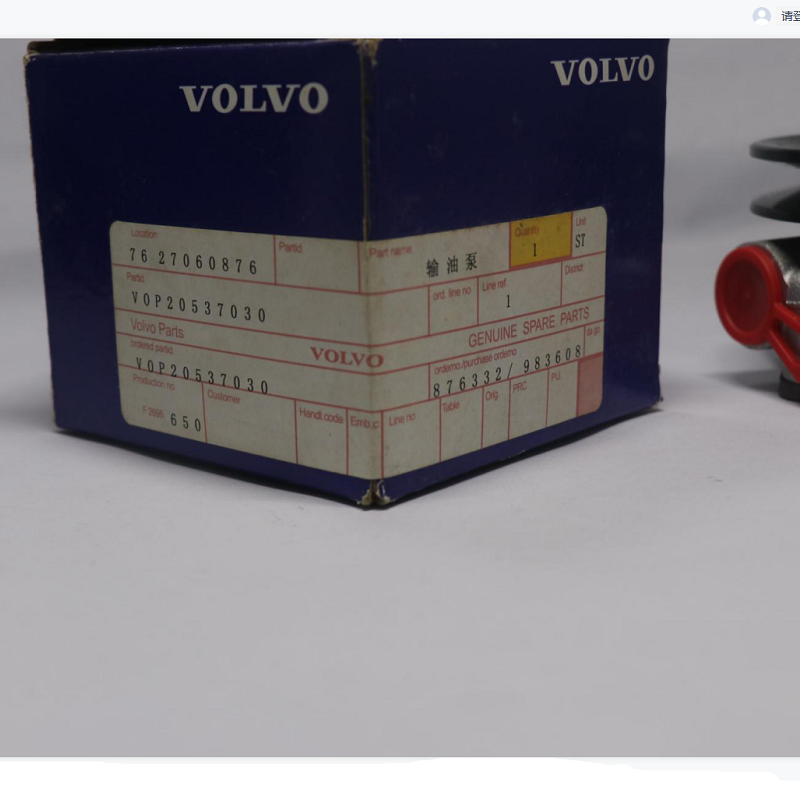

720 Fuel Supply Pump 20460417 (Yellow Wheel V10) KALMAR 02112673 /923976.2497 Excavator Construction Machinery Parts 20537030

the Fuel Supply Pump is an indispensable component in a wide range of applications, ensuring that fuel is delivered to engines efficiently and reliably.

720 Fuel Supply Pump 20460417 (Yellow Wheel V10) KALMAR 02112673 /923976.2497 Excavator Construction Machinery Parts 20537030 - Advanced Analysis

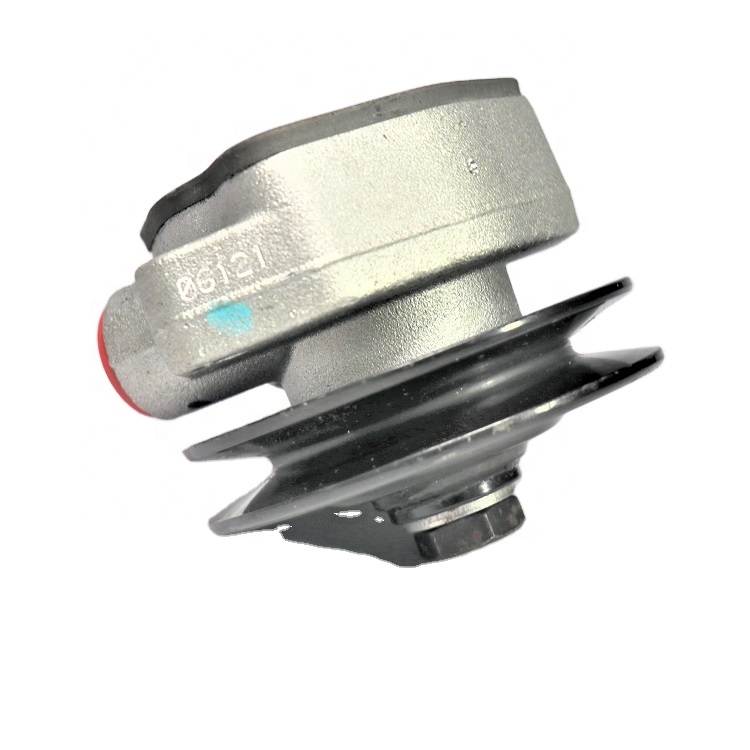

Product Description: 720 Fuel Supply Pump

The Fuel Supply Pump is a critical component in fuel delivery systems, designed to ensure that fuel is supplied consistently and efficiently to the engine. Whether in automotive, industrial, or marine applications, the Fuel Supply Pump plays a vital role in maintaining the performance and reliability of engines. By pressurizing the fuel and delivering it to the fuel injectors or carburetors, this pump ensures that the engine receives the correct fuel flow and pressure, which is essential for optimal combustion. Without a properly functioning Fuel Supply Pump, engines may experience poor fuel delivery, inefficient combustion, or even total engine failure.

In the automotive sector, the Fuel Supply Pump is commonly found in vehicles with internal combustion engines. These pumps are designed to transfer fuel from the tank to the engine’s fuel injectors or carburetor. They are often equipped with mechanisms that maintain fuel pressure within a specific range to ensure smooth engine operation. As fuel is pulled from the tank, the Fuel Supply Pump ensures that it is delivered to the engine at the appropriate pressure and flow rate. In modern vehicles, fuel pumps are often electric, ensuring that fuel is delivered more efficiently, with better control and monitoring than older, mechanical models.

The Fuel Supply Pump operates by creating a pressure differential between the fuel tank and the fuel injectors, forcing fuel to flow through the system. The pump is typically controlled by the engine’s electronic control unit (ECU), which monitors various engine parameters and adjusts fuel delivery accordingly. This control helps optimize engine performance, fuel efficiency, and emissions. Additionally, the pump includes a filtration system to ensure that the fuel remains clean and free from contaminants, which is essential for the longevity of the engine and fuel system.

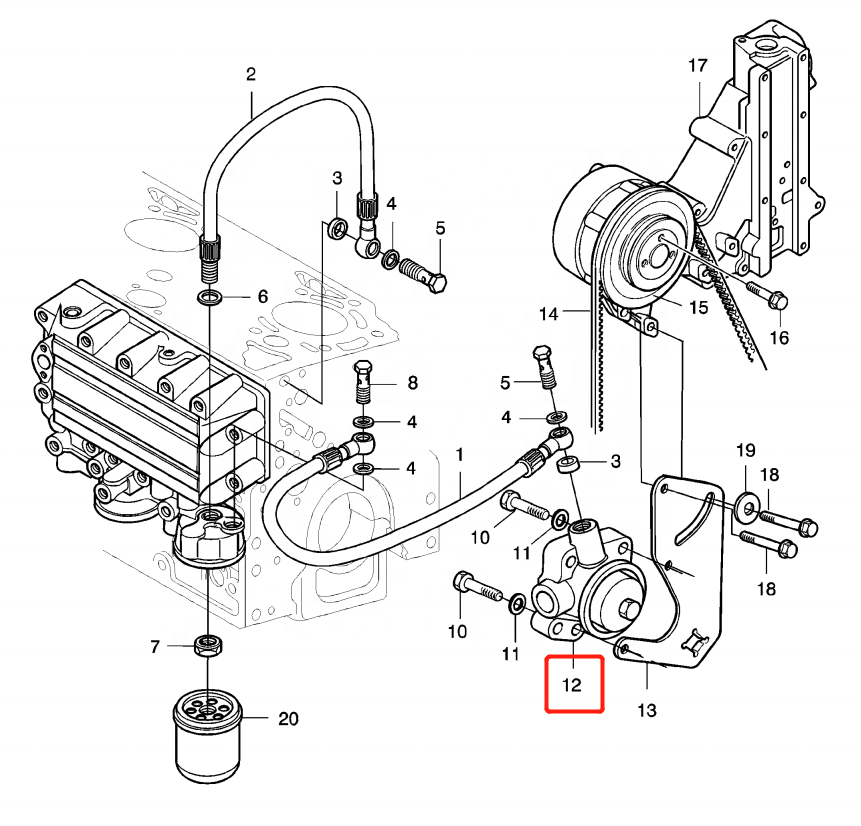

In industrial machinery and equipment, the Fuel Supply Pump is essential for ensuring the proper fuel delivery to diesel engines and other combustion-powered machines. These pumps are designed to handle the rigorous demands of large machinery, such as construction equipment, generators, and agricultural machines. In these applications, a Fuel Supply Pump must be durable and capable of delivering a steady and reliable fuel supply under varying conditions. Given the often harsh environments in which these machines operate, the pump is engineered to withstand dirt, dust, and vibration, ensuring uninterrupted operation.

Marine vessels also rely on Fuel Supply Pumps to ensure the proper fueling of their engines. Marine environments pose unique challenges, such as exposure to saltwater and corrosion, which makes the Fuel Supply Pump a critical component for maintaining engine performance. These pumps are built with corrosion-resistant materials and designed to operate reliably in the demanding conditions of maritime environments. In addition to the basic function of fuel delivery, marine Fuel Supply Pumps are also equipped with systems to prevent fuel contamination and ensure smooth operation in both calm and rough seas.

In addition to the primary function of transferring fuel, Fuel Supply Pumps often feature additional components like pressure regulators and fuel filters. The pressure regulator ensures that fuel is supplied to the engine at the correct pressure, preventing damage to the injectors or carburetor. The fuel filter removes any dirt, rust, or debris from the fuel, ensuring that only clean fuel reaches the engine. These features help to enhance the overall reliability and efficiency of the fuel system, minimizing the risk of fuel-related issues.

The importance of the Fuel Supply Pump extends beyond just engine performance. A malfunctioning pump can lead to a variety of problems, such as fuel starvation, engine misfires, or poor fuel economy. In some cases, a failed pump can even cause a complete engine shutdown, resulting in costly repairs and downtime. To avoid such issues, it is important to ensure that the Fuel Supply Pump is regularly maintained and replaced as needed. Many modern pumps come equipped with self-diagnostic features, which can alert the operator to potential issues before they result in a failure. This early warning can help prevent major system failures and extend the lifespan of the engine.

The Fuel Supply Pump is typically installed in the fuel tank or near the engine, depending on the system design. In some applications, the pump is located inside the tank, submerged in fuel to keep it cool and lubricated. In others, the pump is external, where it is driven by an electric motor or mechanically by the engine itself. Regardless of the installation method, the Fuel Supply Pump is always designed for easy access and maintenance to ensure reliable performance over time.

As fuel system technology continues to evolve, modern Fuel Supply Pumps are becoming increasingly sophisticated. Advanced features such as electronic control, variable speed motors, and integrated filtration systems are improving fuel delivery precision and efficiency. These pumps are designed to meet the ever-growing demands for fuel economy, reduced emissions, and improved overall performance in all types of engines. Whether in a car, industrial machine, or marine vessel, the Fuel Supply Pump continues to be a cornerstone of efficient engine operation.

In conclusion, the Fuel Supply Pump is an indispensable component in a wide range of applications, ensuring that fuel is delivered to engines efficiently and reliably. Whether for automotive, industrial, or marine engines, these pumps are designed to optimize engine performance, fuel efficiency, and emissions control. Regular maintenance and timely replacement of a Fuel Supply Pump are essential to avoid fuel delivery issues, protect the engine, and ensure smooth and reliable operation.

Bulk Source 720 Fuel Supply Pump 20460417 (Yellow Wheel V10) KALMAR 02112673 /923976.2497 Excavator Construction Machinery Parts 20537030

Direct Factory Pricing | OEM/ODM Customization | GRS Certified Materials