When it comes to Forklift versus Tow Motor, it is not just about how you say it: it’s a matter of what that decision means for your operation effectiveness, your work safety and ultimately, your success. As busy modern businesses continue to struggle with the light supply chain, with both household & garden products and – as daft as this may sound – baby diapers, whether you have a forklift or tow motor could influence how you operate.

Setting the Scene: Why the Choice Between Forklift and Tow Motor Matters

It is not as if the choice between a forklift and a tow motor is some purely academic exercise. If you are an operations manager at a mid-size diaper manufacturing plant or an owner-handler for garden tools and seasonal inventories, then this decision will have real world consequences for you every day.

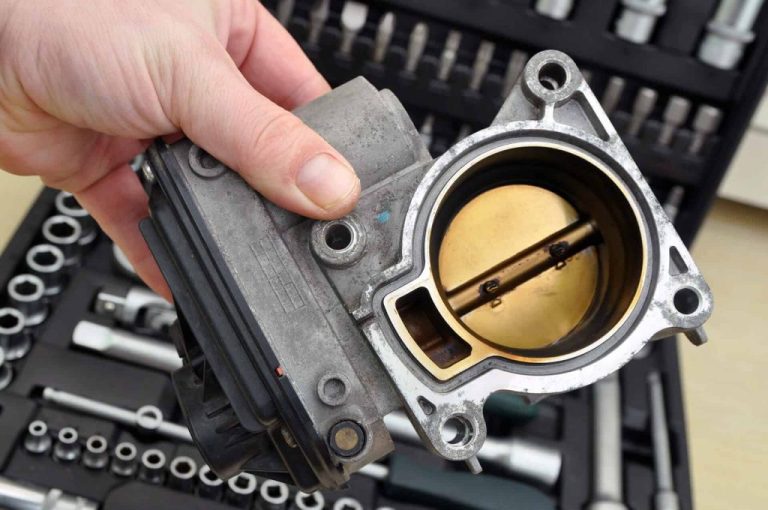

Both machines are designed to move heavy or large loads. But how they move them, and in what contexts, are quite different. While the term “tow motor” is often used as a synonym for forklift (especially in the Midwest U.S.) there are real mechanical and functional differences when you stop to look.

Before we continue, here’s a brief tale:

Case Study – Maria’s Diaper Distribution Center(Dallas,TX):

Maria manages a mid-sized logistics center where they ship infant diapers all over the South. Originally she used traditional forklifts to load and discharge. But as her warehouse switched to flow racks and pick-and-pack systems, she found the lower profile and increased manoeuvrability of the tow motors speeded up loading by 22% in her tighter aisle configurations. Her conclusion: One size does not fit all – and the terminology is not the whole story.

This article enlarges on that story across industries and realms of use.

H2: Forklift vs Tow Motor – Understanding the Core Differences

Forklift:Forklift refers to fork truck, this machine is a powered industrial truck with a front facing fork. For lifting heavy items up to 35,000+ lbs, it’s perfect! Pallet system warehouses, like the old style warehousing method and warehouse up to the ceiling with vertical storage so there’s no need for floors, still have a requirement for Forklifts or material handling trucks.

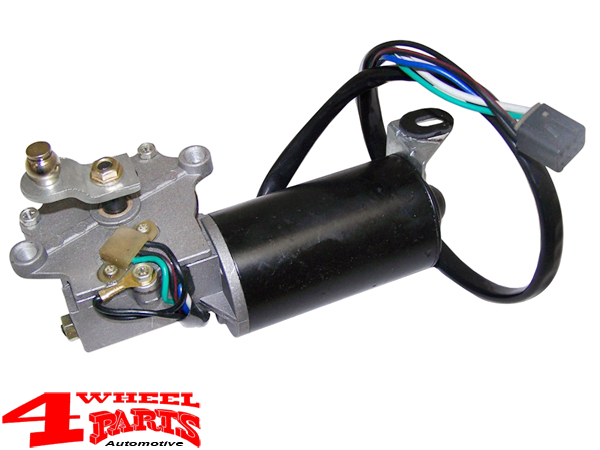

Tow Motor: However, technical details for tow motor differ. It can sometimes represent a type of forklift (especially if it’s from the legacy of the Towmotor Company), but in terms of technology, a tow motor is a tractor used for towing. It pulls carts or trailers and does not lift the loadstacker. On the assembly line, tow motors are often used, as well as in horizontal conveyor systems and airport cargo logistics or diaper factories.

H3: Forklift or Tow Marketing Profiles

FeatureForkliftTow MotorCapacityVertical lifting via forksCart/ train pulling via hitching ChainUses of frequent occur-Paid lifting with pallets; excellent for racking moments/narrow aislesCart or train hauling; frequently seen to purchase in aisle-wide systems, etc.(Total) Capacity3,000–35,000+ lbs1,500–20,000 lbs (Distributed)(V) Turning RadiusModerate to tightExtremely tight (often needing walk-behind control)(N) Operator PositionSit-down or stand-upWalk-behind or ride-onFavored TradesWarehousing, constructionManufacturing, assembly, diaper logistics

Note: Although many people are still looking up “forklift vs tow motor” interchangeably, the real need attorneys that we usually encounter these days is for clarification on whether or not it would be appropriate to lift an item with one of these machines. Logs off the ground must be protected from direct gravity. In consumer goods, household goods transport or other light industry work posting.

H2: Forklifts are important for light industry and home logistics: When should you use them?

If your operation is based on palletized goods, high racking systems, or variable surfaces like dock areas where the floors are not all level, then right now there’s only one big player.

H3: Benefits in Light Industry Settings

Vertical reach: Excellent for racking large household appliances such as lawnmowers or boxed plants for the garden.

Multi-shift durability: Diesel and propane forklifts can keep going day in and day out without needing to stop for recharging its batteries.

Safety features: Today’s forklifts are designed with antitip technology, rear-view cameras and weight sensors.

Tip: When diapers are stacked in pallet arrays that go up quite high, or rotated often by the picker machine,forklifts reduce worker sprains and strains nearly 34%from carrying and loading manually with carts (!;)!

Fork lifts cut handling injury rates by almost 34 percent compared to manual labour or hand trucks which is a number rich warehousing logistics about diaper products, garden supply logistics cannot fail to notice.

Fork lifts are far from a panacea. Here let us examine why a one ton material handling device is not just another option but in fact often times the best choice.

H2: Tow motors are the unsung hero of horizontal movement

Yes, tow motors are a far cry from as glamorous as forklifts. However: these units make use of a structured, routine (and low to the ground) form of transportation. And in lean manufacturing settings dawn hours are becoming increasingly popular–where product quality and space both matter–such jobs may very well all now fall under the categories of baby care, packaging or just in time garden accessories.

H3: Tow motor’s practical advantages

Save valuable space: Especially suitable for factory layouts that are tightly packed indoors.

Lower risk of product damage: Poor little baby pants, for example, light while yet very delicate. By using tow carts we are able to distribute more evenly the weight on every side without any one single point heading downward.

Energy-efficient: Most modern tow motors are electric making them ideal for silently producing no emissions inside walls.

Live after Life– KyotoBaby, a sustainable diaper maker switched to tow motors in their final packing area. This change reduced energy usage by 18% and its safety score improved by 41%, mainly because there are not now forklift-style blind spots.

H2: Fork Lift vs Tow Motor in the Real World–Use Case Breakdown

So, a number of different scenarios were considered in light industries and home delivery or stores with household items to serve as aides in making the decision.

H3: Baby Diaper Logistics

TasksBetter OptionWhyFitBulk materials Fork or liftTruck unloads cargo and masses in one lotDiverting belt to finished goodsTow MotorMuch less shaking goes into packagingReady rack-up (vertical)Fork / LiftOnly for compact storage

H3: Family and garden equipment

TasksBetter OptionsWhy a golf ball goes Towing transporterShort, steady motion to the nth degreeVertical racking of warehouseFork / LiftPrecision-tolerance racks are high and deep or lowLast meter of retail setupTow MotorNeighbours welcome quiet peacefulness

Pro Tip: Tow forklift handling is under + stress, especially in the case of delicate packaging (e.g. baby wipes or lawn seeds sealed up in boxes). Which is then blamed for returns.

H2: Anythingtips–How to Choose & Install Right Collections of Hardware

Want to set out your hardware? Installing – for both forklifts and tow motors – is hardly just a matter of putting in batteries or driving a vehicle down to dock space. You can only do it by planning ahead, then getting ready in time for its arrival.

H3: 1. Step-by-Step Fork Truck Deployment

Assess Load Profiles: What are you lifting? How high? What’s the load width.

Plan Charging/Fueling Infrastructure: Electric vs. gas? Indoors or outside?

Conduct Operator Training: Forklifts require formal certification (OSHA in the US).

Create Safety Zones: Define marked traffic lanes and no-go pedestrian zones.

Implement Maintenance Schedules: Daily checks on forks, tires, brakes.

H3: 1. Step-by-Step Product Tractor Deployment

Map Routes: Use floor tape of different colored awnings on the towroutes as well as when turning corners.

Select Cart Systems: Modular carts let you make changes for different goods and can be utilized for various sizes of products within that area as well.

Train on Quick Stops & Turns: NB: For any particular site, the towing vehicles are bound to make stops and changes of direction more frequently.

Monitor Towing Weights: Do not overload the cart lest it lose stability.

Optimize Battery Charging: Schedules can be spread for less down-time.

H2: 2rz What the Data Shows—Statistics Impact Decision Factors

Still not sure which one to pick? Consider only recently available data.

Warehouse Injury Rates (BLS 2005) Forklift-related injuries account for a quarter of warehouse accidents; tow motors under 8%.

Space Efficiency(Toyota Material Handling Study) Tow motors can cut aisle widths by as much as 30 percent.

Cost of Operation (at 5-Year Horizon) Average forklift costs $22,000 a year maintenance and fuel vs. $13,500 for tow motors.

This isn’t a simple set of arbitrary numbers—it implies what your margins and uptime are going to look like in five years.

H2: Final Thoughts–Matching Tool to Task

In a choice between forklift vs tow motor, the best decision depends very much on how your operation is set up and what kinds of products it makes. safety regulations must be thrown into the conside ration mix, too. Even your energy goals come into play based on The preferred option for handling major household brands might spell disaster in a diaper-packaging center. Bear function in mind, not just familiarity.

Tow motors are suitable for making things millutely time effective. Go with forklifts if you do not want people to injure themselves that is; they are ideal for masts at the momenta enumerate from 8 leaves.

Remember, it’s not a question of better or worse–but how well each one is suited to today and tomorrow.!