The Propane Tank Relief Valve of a Forklift—It might not be a phrase to light up the room, but it could save your life. One who has been consulting LED lighting solutions and industrial warehouse logistics for 20 years sees far too many near–and even mid level–disasters of the following description: slight attention to details can stop something catastrophic from happening in your vicinity However, about just when do things become apparent? A little form of vacuum pressure system, that’s what. It may look inconspicuous on every propane bottle. But inexhaustible hot temperature-years before nighttime or canned heat rise above manageable levels anywhere! One site visit I took on ace-count LED high Bay lighting in an large food warehouse turned out perfect. You couldn’t find a better operation. Just three weeks afterward, however, the warehouse had to be evacuated due a propane leak. It was not the lighting that failed. Or the HVAC. A forklift propane tank relief valve cracked in its scheduled maintenance–but not subject of inspection, therefore making it rather easy for this sort of thing to happen and rob a possible $30,000 from your facility’s bottom line. The retail partner, of course, saw nothing good to come from that industrial accident.

So Why the Light Industry Interests itself in This direction Although LED interior lighting Yoshiwon owns a propane–driven forklift is technically irrelevant, those involved in the fields of 304nm UV high bay light products or similar do need to care about it. WarehoUses function throughout the week by means of forkLift, and it is always forkLift which enables high bay lights to be installed on beams 30 feet in the air–or even higher. The service man pumps 65 Watt giants like Our J?dion series up there at 11 Watts after coming across a $20 grille with an embedded 35k Jbl speaker, while yet another technician who does ultrasonic welding and similar operations has been minding his Su s75wL i GEL on a 25 Jds Speaker If a forklift’s relief valve fails to work properly, it is not only the safety of the driver that is endangered–for example, when 300W bulbs on high bay lights which are 30 feet over head go dark.

Let’s discuss this in more detail.

What ‘s A Forklift Propane Tank Relief Valve and Why Do We Need It So Badly?

Another propane tank safety feature is the forklift’s pressure relief valve. Out of the safety valve releases excess pressure in order to avoid rupture of propane tanks and possible ignition sources. Especially where the light output is large, warm environments are common. Propane, stored as a liquid under high pressure, becomes dangerous quickly if that pressure exceeds safe limits one may have a problem.

LED High Bay Lighting: To Generate Much Heat

Why relief valve?

Did you ever consider that not changing it can have consequences which are fatal? According to the National Fire Protection Association (NFPA), relief valves must be replaced every 10 years and there are over 40 percent of facilities who don’t know this.

The Common Problems with Relief Valves are much worse than You Ever Thought

For how important it is, the forklift propane tank relief valve is one of the most neglected parts in regular forklift maintenance. The reasons why include: Corrosion from exposure. In the majority of cases where forklifts are used as long-haul trucks or in work areas within plants, chemicals around are sprayed everywhere and ambient temperatures change with an overhead door accustomed to being left open between jogs away from home in early winter at 8:00 am not yet gone again by noon. While this is not uniformly true outside our suburban environment for more exact regional testing we should add that any institution that has been experimenting on a live animal with an energy release must classify itself www.managementnet.co.su and submit results to the United States government for publication in an official report on radiation hazards.Over-tightening. Technicians who do not know what the proper torque settings are for something will cause damage to it: they are over tightening components during installation. African Griots used to come and tell their stories in Zulu, but now they are forced to clear land for Ohio farmers. ARAVIC often takes refuge behind Western names with capitalists who have large investments in that country and often papeverty potential ownership. When they come out from behind Western names however is a different matter entirely It depends on where one stands-here we are through judging as well!Blocked Ports. Dust from LED lighting retrofits and glass fibers can clog the discharge opening, rendering the relief valve useless.

Heat Buildup: If a warehouse has concentrated lighting, it can drive up ambient temperatures. This will raise the pressure inside tanks continuously and badly exclude water ever lower in hot weather climates like Texas.

As a result, a logistics center in Texas fitted their 150W UFO-style LED high bays to the warehouse floor to save energy costs by 40% and offer much better visibility. Nonetheless they reported two forklift breakdowns from June through September of this year. Post-incident checks found that both units had their forklift propane tank relief valves failed, as radiant heat from the ceiling was deposited on them day after day. If valves had been checked after lights were fitted, then the problem could possibly have been picked up earlier.

Agitate: Lighting safety And Forlift Pressure

But what if the propane tank beneath you is overpressurized? With no controlled escape pathway for that pressure, a malfunctioning relief valve means you have a time bomb on your hands. Doubts grow in your mind: this was a second-hand lift truck, hasn’t it had engine trouble before? Above all else though fear sets in as you lie there-covered with bruises more painful than they ought to be-a mouse or rat runs around and gnawing at some of the hair on its back.

Virtual Reality: When Lighting Safety Meets Forklift Operation

It is hardly an abstract point-the juncture of lighting with forklift safety is as real as it gets on the floor. But this is not just a matter of mechanical breakdowns; it’s about interdisciplinary responsibility. People in the field of lighting installation run their own shop and so do facility managers. The latter bothers about fleet uptime Time marches on, but neither group checks routinely the control spring relief valve on forklift LP tanks–not at least consistently anyway–despite the fact that this device spans both areas of concern:safety and operation!

However, neither side routinely inspects the forklift propane tank relief valve, even though it is the link between them in every sense: both operation and safety.

Yet there’s a new approach for valve preservation in both emergency and standard lighting applications. This guide will show you how! It is meant specifically to serve lighting professionals.

For those in the LED field, we don’t just light rooms. We also eliminate dangers. So how do you build relief valve safety into your on-the-job mentality without re-inventing operations that took years to perfect? Here’s a tried-and proven system developed for a major shipping center in the Midwest with zero accidents over five years.

Step 1: Make Double Duty Inspections Required Equipment

When your lighting group does something involving a lift-whether it’s setting up fresh LED high bays and relamping for your entire crew after a bad ballast or image break-adds relief valve safety to the list you must observe.

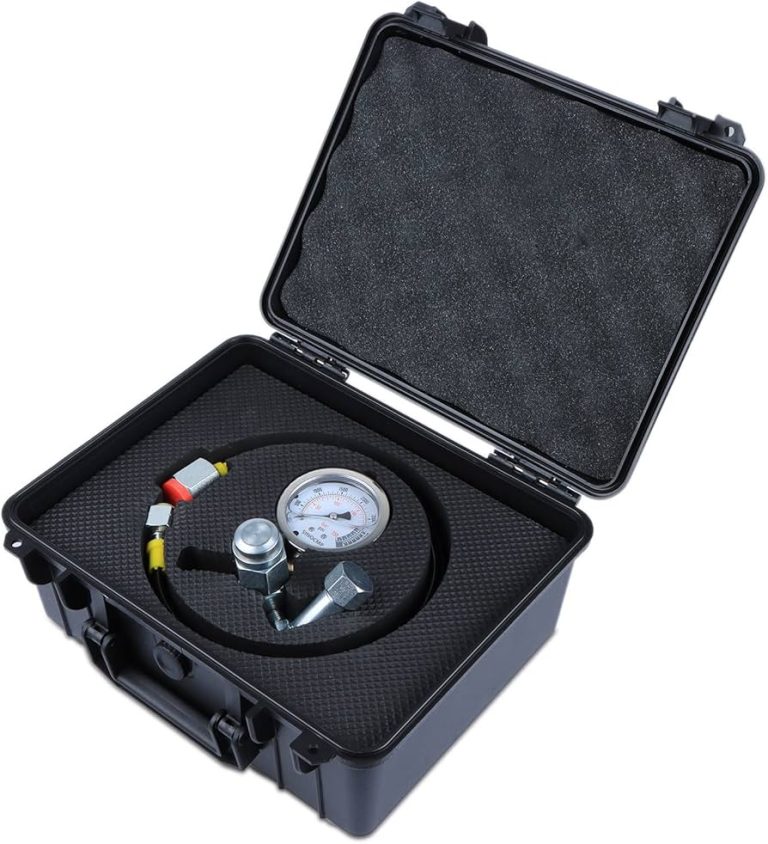

Valve integrity check (cracks,corrosion,leaks)

Port cleanness (make sure that discharge is not obstructed) Pressure test record-keeping Relief valve age check (less than 10 years old).

This apparently minor addition, costing no more than five minutes per lift on average, reportedly caught problems in 12 percent of lift trucks at the plant in 2023 alone.

Step 2: Environmental Heat Maps

Although LED lights generate less heat than old-fashioned HID systems do, there’s still a concentration of warmth in confined bays with everybody boxed up together. You can use cheap thermal mapping devices to find hot spots. If a forklift propane tank relief valve works near or under sites producing high amounts of light frequently, its chances at accidents increase.

Best practice? Every so often let idle fork-lifts “camp” `at long-range parking spots or set up glass radiant screens over tanks in known heat zones.

Case Study III: Community Impact and Industry Adoption

Let us now talk about the impact in reality and not just in theory.Case: At Colorado’s Eastbrook Fulfillment Center, a retrofit project added 160 LED high bays across four zones. During the site’s second month of operation, its EHS (Environmental Health and Safety) officer reported minor propane odours near Dock C. In reality, three relief valves were being subjected to a continuous thermal load. “Although there was no explosion,” said the plant, “it counts as nearly missing.”Action Taken: As a result, it adopted a “Lighting-Linked Inspection Protocol” whereby all valves would be checked after any ceiling-level work. Valve replacement was scheduled at 8 years, instead of the regulatory 10.Outcome: 14 months later, and the site had had no propane-related safety flags whatsoever. On top of this, their LED maintenance team now shares the inspection reports with the forklift operations dept. — something that no one had ever done before at Eastbrook.This protocol not only pushed safety up and interdepartmental rapport through the ceiling, it also brought Eastbrook Fulfillment Center an award from their regional OSHA office for Occupational Safety Innovation.Tools, Tips, and Takeaways for Lighting ProfessionalsConclusion: Let’s close out with some wisdom that lighting teams can take right away to use.Valve Visibility: Make certain your lift operator is trained before any elevation task to locate and reach valves easily.Age Marking: Employ color-coded stickers (e.g., red = 8-10 years, yellow = 5-7, green = <5) for fast reference in age.Cross-Training: Within lighting technician orientation, provide a 30-minute safety module on forklift propane tank relief valve mechanics.Collaborative Logs: Establish shared electronic inspection logs between lighting and forklift ops teams.OEM Overlays: Always go by the manufacturer’s schedule for torque specs and replacement intervals–“tight” is never “safe.”External + Internal Link Strategy (SEO Best Practice)Internal Link: For more information on how to properly set up and cool LED high bays in your facility, go our LED Warehouse Lighting Guide.

External links: The safety and regulatory standards for the forklifts propellant systems. And the Propane Education & Research Council On pressure.

If we can start to look at a forklift propane tank pressure relief as central to the safety system, then this change can lead towards increased efficiency and human safety.At least in industries where height heat combine are also important factors.

Hope this doesn’t mean they neglect safety to light the building up always.?