Brand New for KALMAR Car Alternator Pulley 923829.0681

the Alternator Pulley is a vital component in any system that relies on an alternator for power generation.

Brand New for KALMAR Car Alternator Pulley 923829.0681 - Advanced Analysis

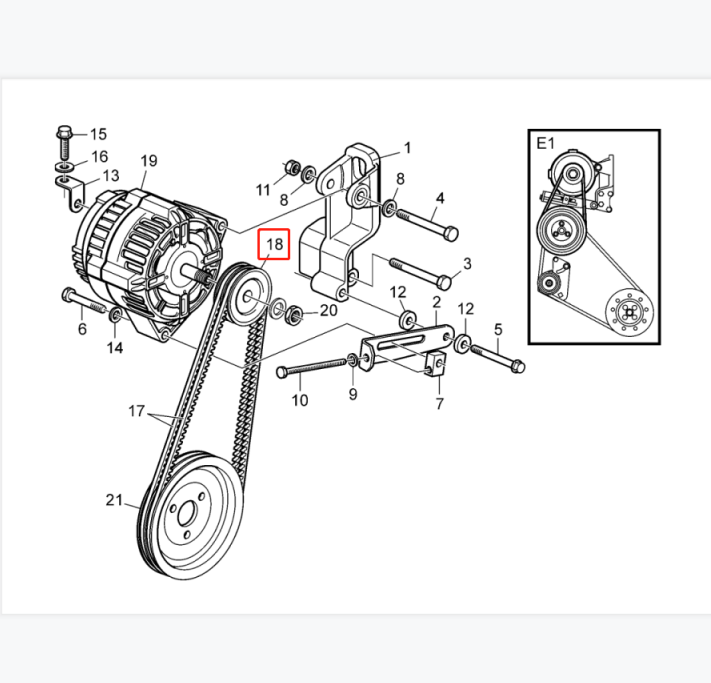

The Alternator Pulley is a critical component in the operation of an alternator, providing the necessary mechanical connection between the engine and the alternator. It is responsible for transmitting rotational power from the engine’s crankshaft to the alternator, allowing the alternator to generate electricity. The pulley is mounted on the alternator’s shaft and is typically connected to the engine’s drive belt, ensuring that the alternator operates at the appropriate speed to charge the battery and power electrical systems in a vehicle or machinery.

The Alternator Pulley plays a vital role in ensuring that the alternator functions efficiently. By transmitting power from the engine, the pulley allows the alternator to generate the electrical current required to power the vehicle’s systems, such as lighting, air conditioning, and the ignition system. The performance of the alternator is highly dependent on the proper functioning of the pulley, as a malfunctioning or worn pulley can lead to undercharging, overcharging, or even complete alternator failure.

One of the key features of the Alternator Pulley is its design to handle the demanding rotational speed and torque generated by the engine. It is typically made from durable materials such as steel or aluminum, ensuring that it can withstand the stresses of constant operation without experiencing excessive wear or failure. Additionally, some alternator pulleys are equipped with a built-in clutch mechanism, which helps to reduce strain on the alternator by allowing it to decouple from the engine under certain conditions. This helps prevent damage to both the alternator and the engine, ensuring smoother operation and extending the lifespan of both components.

The Alternator Pulley is often designed with a ribbed or grooved surface to improve the grip and transfer of power from the engine’s drive belt. This ribbed design ensures that the pulley maintains a secure connection with the belt, preventing slippage and ensuring that the alternator operates at the proper speed. In addition, the pulley is typically fitted with a bearing or bushing to reduce friction and provide smooth rotation, which is essential for efficient power transfer and minimizing energy loss.

In modern vehicles and industrial machinery, the Alternator Pulley is often part of a larger serpentine belt system that drives multiple accessories, including the alternator, air conditioning compressor, power steering pump, and water pump. The Pulley must be precisely aligned within this system to ensure that all components work in harmony. If the pulley is damaged or misaligned, it can lead to problems such as belt wear, engine overheating, or insufficient power generation from the alternator.

Over time, the Alternator Pulley can experience wear and tear due to constant exposure to heat, friction, and engine vibrations. Signs that the pulley may need replacing include squealing noises, failure to charge the battery, or a slipping drive belt. Regular inspection and maintenance of the Pulley are essential to ensure the continued efficiency of the vehicle’s electrical system. Replacing a worn or damaged pulley can prevent further damage to the alternator and other components in the engine’s drive system, saving on costly repairs and downtime.

In addition to its primary function in automotive applications, the Alternator Pulley is also used in various industrial machinery and equipment. These applications include power generators, agricultural machinery, and construction equipment, where reliable and efficient electrical power generation is essential. In these settings, the pulley helps drive the alternator to ensure that the machinery has a consistent supply of power for operations.

In conclusion, the Alternator Pulley is a vital component in any system that relies on an alternator for power generation. Its role in transmitting rotational power from the engine to the alternator ensures that the vehicle or machinery operates efficiently and reliably. Regular maintenance and timely replacement of the Alternator Pulley are essential to ensure that the alternator continues to function correctly and that the vehicle or equipment’s electrical system remains in optimal condition. Whether in automotive, industrial, or commercial applications, the Alternator Pulley plays an essential role in the proper functioning of the alternator and the overall system.

For more information on regulations and standards governing automotive and industrial components, including the Alternator Pulley, you can visit the official website of the National Highway Traffic Safety Administration (NHTSA) at https://www.nhtsa.gov/.

1. Durable alternator pulley for reliable power generation

2. High-performance alternator pulley for automotive systems

3. Long-lasting alternator pulley for industrial machinery

4. Efficient alternator pulley for smooth engine power transfer

5. Replacement alternator pulley for optimized electrical systems

Bulk Source Brand New for KALMAR Car Alternator Pulley 923829.0681

Direct Factory Pricing | OEM/ODM Customization | GRS Certified Materials