The hydraulic valve of Toyota forklift fails, is only a little problem at first sight. But in high pressure world of construction and metal window business, these are kind of technical debts that peacefully accumulate, and then fiercely attack before you know the reason for sure.

The problem isn’t only leaking hydraulics or lifts that jerk about. It’s about workflows locked-in-place all at once disrupted, project delays, and the quiet cost of downtime construction crews seldom expect. They never see it coming—until they’re hit with enough bills ?£ hundreds per extra day on site.

Why You Should Address The Toyota Forklift Control Valve At Once

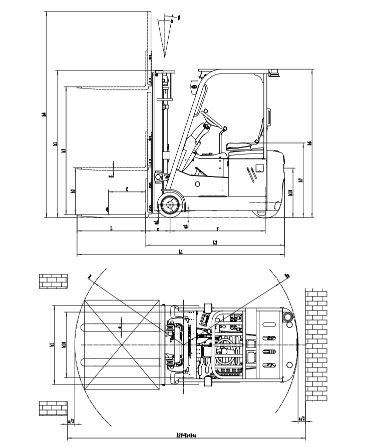

Forklifts, especially those from Toyota, are deeply embedded in the daily operations of materials like aluminum frames, composite cladding and finished metal doors. They are used to move loads from warehouse racking systems out onto open job sites–often over uneven terrain. And at the very core o f this machine lies its hyd raulic brain: the control valve.

The control valves manage the flow and pressure at each outlet for hydraulic fluid. In Toyota forklifts, this isn’t merely a switch with two positions. It’s a precision device that affects the lift, tilt and side shift functions, as well as multifunctional grippers such as rotating mechanisms or clamping jaws. A worn-out Toyota forklift control valve does not only slow things down. It poses the hazard of lost loads, slippage and even in serious cases, personal injury on site.

The Unseen Cost -accumulated Technical Debt in Equipment Maintenance

Let’s make a parallel example from software engineering world: technical debt. This occurs when shortcuts– such as rainy day maintenance or putting off valve cleaning–begin to stack up. Like in code, every procrastinated repair is splayed onto a bed of ever-increasing complexity and risk.

For example, there is the standard story of an Arizona medium-size steel window business focused on energy-efficient installations that realized its Toyota forklifts were “unstable at the incline.” However, business was brisk. There were orders waiting to be executed. Why not put off replacing or repairing the valve till later–until a half-lifted carton of thermally broken window frames collapsed and it caused over 40 thousand dollars ‘ worth ? of damage to inventory.

Postmortem analysis? Faulty Toyota forklift control valve due to internal wear and fluid contamination.

The penalty on their technical debt was hard to meet.

What Are the Signs of Valve Failure on Sight?

If you are in the metal window construction or iron window production businesses, consider it your early detection system and warning:

Erratic or slow lifting movements

Hydraulic assembly emits abnormal whistling ?, vibration

Hydraulic fluid leakages on top of or around the valve block

Side shift or tilt operations become unmanageable

Normal loads cause anchoring capacity to decrease

These signals are not isolated events. They are information at the system level, loud and clear, that your Toyota forklift’s control valve is teetering on its last legs.

When Downtime Erodes Windows and Doors: Margin Loss in the Supply Chain

Just imagine it-you’re there with a metal door unit which has been factory-finished and is waiting to be installed. Unfortunately, before setting the pallet in place your forklift’s intermittent control valve fails. The deadline from the customer? Four hours are past. You’re too late. Now your contract for logistics adds on a late delivery penalty clause— $1,200

Guaranteed Not only that, but a multitude of small mistakes winds up wrecking confidence at large. Your trademark gains a negative reputation among contractors and developers alike. These are not theoretical scenarios; they are now occurring in the green-field North American construction sites of lean construction ?.

Unplanned forklift downtime costs the building supply chain US$3.2 billion annually, or so says the Material Handling Institute. A full 22% of this can directly be pegged to hydraulic sub-system trouble-most commonly traced back down on old, poorly maintained control valves.

How to Solve: Campaign Setup to Eliminate Technical Debt in Forklift Systems

Step beyond fighting fires.Let ’ s try a more reasonable, comprehensive method of dealing with real-world phenomena.Take Toyota forklift control valve problems in high demand conditions as an example: all you need is willpower and a proper plan of action, plus methods that are down to earth.Start of 1: Inventory Your Fleet for Valve Age & Usage HoursDraw a map of your forklift fleet.Counting counts: how long since the last valve facility was operational. Toyota recommends servicing control valves every 1000-1500 hours, depending on what kind of load patterns and environment.Traditional knowledge: Construction zones, for example, in which there is metallic dust (eg: grinding, cutting) in the air increase valve wear significantly. Adjust inspection periods down accordingly.Step 2: Implement Predictive Maintenance via Sensor LoggingModern Toyota forklift models support sensor kits that monitor pressure fluctuations, temperature and hydraulic flow. Recording this data makes it possible to intervene before a breakdown affects operations.Step 3: Get Operators to Recognize Early Symptoms of Valve FaultsTrain a new section: short, visual and dedicated to this issue alone. Teach your crew the difference as one sees looking straight ahead of another ‘normal ‘ lift feel and some valve-caused aberration. The more eyes and ears there are in quickness response we have.Step 4: Only Use OEM or Certified Valve KitsAgain, the lure of low cost may be tempting on parts. But a great many of these lack the tolerance levels or resistance to corrosion built into Toyota-authorized kits. It is true in long-term use? OEM wins out across all fields (Total Cost of Ownership).Step 5: Connect Control Valve Risk to Revenue KPIsLink the techevent with numbers: a simple formula

Valve Risk Score = Downtime Hours x Avg. Labor Cost/hr + Avg. Missed Revenue per Job DelayThis makes relating maintenance work to the dollar terms that executives can understand, and endorse.

Service Life: A Toyota forklift control valve lasts around 14–15 months. But this is only an average figure: the actual durability of any given valve depends on whereabouts it fits within the total 2,000–2,500-hour service life range. Calibration problems often accelerate wear; if this is happening to your own tools or those on site, take action now. A: In such environments clean air is essential for any hydraulic device’s smooth operation and continued longevity. Dusty, sizzling summers and frigid winters will wear down the life of your Toyota valve. Q: What preconditions precipitate a Toyota forklift control valve replacement? A: When heading out into metalworking environments (like aluminum frame anodizing or direct flow casting) this normally takes place with the hydraulic oil renewal. In a proper, thick atmosphere of fresh fluid and low flow speed, control valves should operate reliably for about 1-\\u00016,000 hours—depending as usual upon wear factors at smaller load levels before they let go altogether. However if an air-powered voltmeter is attached (See photos), problems such as early wear and tear shall become apparent more quickly before a fault develops to begin with. Downtime Hours x Avg. Labor Cost/hr + Avg. Missed Revenue per Job Delay = Valve Risk Score–as this equation reveals the true cost of downtime-plant can no longer put off a maintenance investment.

Q: Can I rebuild a valve instead of replacing it?

A: Certainly.But this depends on the timing of wear, If the problem is caught early. This is a genuine replacement.These kits,available with various model ex-stock and Toyota products,will allow the valves to live a longer life. Still, if internal scoring,corrosion and/or warped spools are encountered, you may find it more cost-effective in the long run to replace the entire thing.

Q: What fluid type is best to prevent valve problems?

A: Always follow the specifications set out by Toyota for hydraulic fluid within the system. In high-contaminant environments, choose a high-grade oil with anti-foaming agents and thermal withstandability. Don’t mix brands; it leads to the breakdown of all qualities and properties.

Intelligent Procurement: How to Choose the Right Valve (and Supplier)

When you are considering sourcing a replacement Toyota forklift control valve, especially for use in critical sectors such as metal window transport or insulated door logistics, think about the following five: OEM Certification: Look for distributors who are directly connected with Toyota or industrial supply networks that have been tried and tested.

Compatibility Matrix: Match the valve itself against the model and year–even similar chassis have details of hydraulic requirements that may vary before production starts but after being launched into market.

Benefit: Pick a provider who gives guidance on installation, warranty protection, and offers after-sales service agreements.

Outlook Reference: Toyota Material Handling – Technical Bulletins Archive

You might also want to look into President’s Choice,Low’s or Grainger for accented replacement valves, or contact your regional Toyota forklift dealer direct if need be. They can help with any questions you might have about the product.Q: How to Choose the Right Valve (and Vendor)

Feedback from Catch, a HubSpot customer who hears his customers say “How come I cannot find any internal shop equipment?”, goes to the topic about buying ancillary products: Interconnects of Depth – Topics You Need To Read Next

To broaden your knowledge and prepare the options for future inefficiency, read: Hydraulic Fluid Contamination: The Silent Killer of Forklift Systems (internal blog post)

How Lean Maintenance Wastes In Fabrication Workflow (external: can also be seen at mhi.org/resources)

Choosing Forklift Attachments To Fit Custom Window Height Dimensions (internal case study)Concluding Thoughts: Control the Valve, Control The Flow-of GOODS and MARGINS

With the Toyota’s monolithic ejector control valve, an entirely new experimental concept was born. Forklift performance had to change forever. Whether design manipulation has for its result a bad idea–the operation of this pump on another line in industrial setting, could potentially trip off entire engines of production. But if nothing is left idle, you can check every instance of redundancy at its source when the line’s performance needs come down (a poor choice for quality control). In these early days of developing our technology, we are nonetheless vigorously determined to correct bad ideas just as soon as we spot them and prevent them from spreading.

In the lightning-paced, nickel-and-dime world of building construction and architectural metal window fabricators, every lift is a fortune. Every minute costs money–or worse yet, time.

If you see your valve system as an asset rather than something slapped in later and forgotten, if it is mapped and maintained all along –then your operations move from one of just being reactive with each new crisis to actually making money. That’s how the technical-debt design trap is escaped and resilience built into a supply chain.

Therfore!