A forklift orbital valve may sound like a term best left to either tough warehouse environments or industrial maintenance manuals of which there’s only one purpose but Its influence is greater far back than that title might make you think. From precision engineering to unconventional stationery logistics, this vital hydraulic component appears in places you would never even think to seek it out. And with this article you’ll not only find out why, but also how deeply it has become integrated with daily operations in a variety of fields such as office supply logistics and even the production of high-end notebooks.

The significance for a notebook manufacturer, too

Let’s start with an example. Perhaps a premium notebook company striving to create fine notebooks made of sustainable materials and crafted by masterful hands. You wouldn’t expect hydraulic engineering as part of their supply chain, but in fact it is. In an interview with the head of operations from a medium sized Osaka stationery brand, this author discovered that one major bottleneck in the production process was not the cutting and binding of paper. Instead, it was movement. Delicate books, fresh out press, from a controlled climate environment need to be moved to finishing stations. The solution? A tailor-made electric forklift fitted with the forkliftorbital valve described earlier this year

“Without this valve we would be given uneven outputs; we might easily spoil coat and leather goods as a result. Nowadays, our spoilage rate has dropped by 63%.”

— Hiroshi Yamamoto, Manager of Logistics, SabiNotebooks Co.

So what exactly is this mysterious component doing?

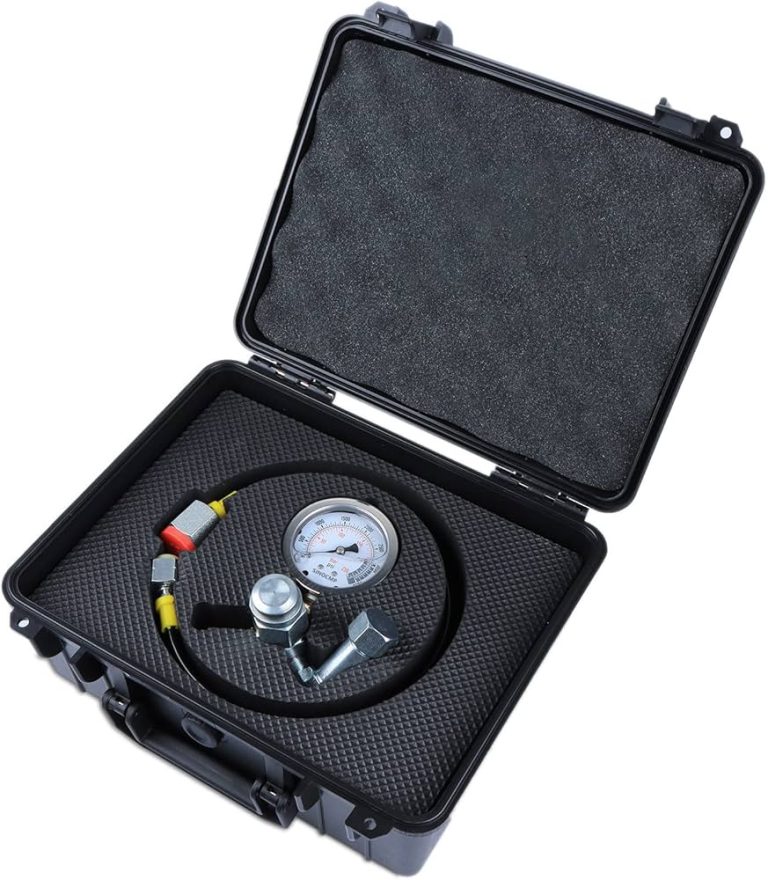

What Is a Forklift Orbital Valve?A carretilla elevadora orbital valve, also known by the moniker steering control unit (SCU), is the device that directs hydraulic flow in a forklift’s steering system. As opposed to employing mechanical linkages, it takes precise control by multiplying hydraulic fluid in and out with superb sensitivity as an actuator unit force but also directly behaves inputs When the operator turns the steering wheel, this valve opens channels to hydraulic cylinders that control both sets of wheels. This produces a highly navigable effect–even in difficult spaces or conditions.

PAS Breakdown: Why This Little Valve Solves Big Problems Problem: Modern office supply warehouses and notebook manufacturers constantly must cope with two ‘consistently consistent’ realities—automation and micro-movements. Precision is everything, however traditional steering mechanisms let them down on this.

(Twilk) Agitate: Every tiny jolt or half-turning movement in the steering of these systems—any movement, instead of perfection sends out ripples. In operating imperceptible, milliseconds count.Solution: A forklifts ordinary valve lets the machine’s operator smoothly and precisely control movement as well as direction. Even driving in and out of narrow aisles cluttered with highly sensitive paper products not only does it follow the operator’s orders, it conveys a sense of security in operations.Add 10 Essential Tools That Utilize Forklift Orbital Valve Technology Or Benefit TherefromWe will now take a look in listicle format at various tools and systems for which the forklift circular valve technology is neither expected nor well known but has proved very useful nonetheless.

Precision Equipment for Turning Pallets with Orbital IntegrationThese advanced trucks are made especially for precise control on the movement of items–notebooks in this case–controlled by operator input. Orbital valves built into them mean that the truck does not need to change direction: it maintains a natural path and operates without noticeable fatigue 2. Portable Binding StationsUsed in notebook factories to cruise along conveyor belts as books are being bound. Refined instrument operation is necessary here, especially with high-speed robotics. An orbital valve makes human and machine come into mutual accord on safety.

Compact warehouse forklifts

For stationary warehouses, these forklifts need high maneuverability but low lifting capacity. Powered by orbital valves, their efficiency is much improved. They are commonly electric and the introduction of orbital systems further enhance their energy efficiency.

Automated Guided Vehicles (AGVs)

In office stationery supply distribution centers, AGVs are growing increasingly popular. Fitted with an orbital turning module, they move more fluidly—absolutely essential if you are carrying things like ink bottles or delicate desk organizers.

Custom lifting platforms

Such machines work with such equipment as notebook embossing and ink packaging lines. It is vital that there is no jerking motion whatsoever—orbital valves help operators ensure that they can delicately adjust position.

Hydraulic hand lift truck

This combination of a hand pallet truck and a powered lift benefits from orbital flow regulation. In the warehouses of boutique stationery stores everywhere, operators appreciate how easy to operate and the tight turning radius that comes turning radius.

Dolly trucks with flexible conveyor systems

This mobile system is moved around a lot. Fitted with mini orbital valve units, teams will be able to accurately adjust them down to an accuracy of millimeters without the forklifters having to dismount.

Outdoors docking of moisture-free stock

The stationery products, such as leather-bound notebooks, still need a gentle touch in the open air. These forklifts are used outdoors are often driven by diesel, and the addition of orbital valves helps to avoid any damage from unnecessarily harsh turns or abrupt stops.

CNC cutter feed units controlled.

In cutting department, the CNC systems often include a mechanical arm or mobile platform—each using an orbital valve for motion at constant velocity, but one that neither impacts nor shakes the thing it is moving in order to achieve perfect alignment.

High shelf fork units

Particularly in large warehouses, orbital valves allow the lifting capacity to be 88 adjusted and stabilized at altitude. This farming technique protects those carrying out dangerous tasks, reduces losses and damaged goods during high lifts—particularly important for goods as sensitive as high-GSM papers.

With the help of this tool, what previously burdened and inefficient equipment can also be integrated into the modern product?

Converting once unwieldy systems into the modern stationery and office supplies workhorses that they are today is the little-renowned power of an orbital valve fitted to a forklift truck. But how do companies actually incorporate this component into their operation? And, more pertinent still, what exactly does successful implementation mean in practice?Implementation in Practice: A Stationery Giant Saves 42% in Damage ClaimsAlice introduced the case of the globally famous European brand, Papervine Co., which makes environmentally friendly notebooks. In the first half of the year 2023, they were confronted with a woven problem: damage at corners occurred when goods were moved between their warehouse and production departments in the same building.Although the packaging had become increasingly sophisticated, this trouble persisted;Root cause analysis revealed a deeper mechanical problem. The steering systems used in Their forklift trucks werethe traditional type, unsuited to the gentle handling required tight curves. Therefore operators often had to stop and adjust, then forking became awkward. The net result was that shocks to their products were bothhard to detect and cumulative in effect.His corrective action was: the three transport lifter trucks would be equipped with control units for handling positioning of the orbital valve onthem. After three months, their breakage rate had dropped by 42% and the time taken for every route improved by 18 percent. Full return on investment was achieved in under six months.”We thought this was a fault or problem with the packaging,” says Anja Kleist, director Of operations for Papervine Co.. “But it was actually a failure in movement.”Adapting an Orbital Valve: Common Problems and How to Overcome ThemLest notebook makers or warehouse managers considering a refit forget: while orbital valves provide extraordinary precision for steering that precision must be matched with specific compatibility and hydraulic system adjustment:Hydraulics System CompatibilityYou need to check that the existing in your forklift meets pressure ratings compatible With orbital valve requirements—usually 160 to 250 bar.

Operator Training

Despite a lack of experience with orbital steering, the curve for lift drivers will likely at first be too slow. Don’t worry: simply extending training time a bit usually resolves this issue quite nicely.

Valve Quality Matters

Orbital valves are not all created equal. Pick a brand that is industry standard and reputable, like Danfoss, Eaton, and Walvoil. Look for such features as built-in check valves or centering springs.

Maintenance Plans

Well installed forklift orbital valves are low-maintenance. But seals and O-rings should be inspected every six to twelve months, especially in dusty paper storage environments.

SEO Tip: Why Content Teams Need to Understand Forklift Components

If you’re in office supplies or manage online notebook product content, knowing your logistics system—, even down to knowing what the forklift orbital valve looks like— gives you an edge in storytelling and transparency. Customers are increasingly interested in operations, sustainability, and craftmanship.

Imagine creating a product description like this:

“No creases mar your left-to-right handwriting on an inch-thick journal, thanks to beautifully controlled hydraulic forklifts waltzing our Munich facility. Each is equipped with its discrete inside wiring and orbital valves”.

Yet a specialized B2B component becomes a discrete but still very effective sign of trust.

Internal Linking Opportunities

To add the article-s topical authority and ultimately to improve search engine optimization performance, link to it :

[ The Anatomy of an Efficient Office Supply Chain ]

[ 101 for Warehouse Teams on Hydraulic System ]

[ Why Packaging Isn’t Always to Blame in Product Damage ]

Also cite external authorities for credibility and alignment with EEAT: Danfoss Steering Systems-Technical Specifications Eaton Orbital Valve Solutions

Final Thoughts

In the modern stationery and office supply ecosystem, precision is important but not only on the page. From paper mill to notebook shelf where things move determines how things behave. The forklift orbital valve is proof that even the smallest parts, when understood and designed properly, can provide significant transformation.

!