Yale Forklift is not just a warehouse problem if the starter motor goes wrong. To those managing technical infrastructure in industries, like network hardware operations and cable logistics experts say that such accidents can also cause the entire schedules of personnel to fall apart. For engineers in charge of shipping computer cables or keeping network kit in storage at distribution centers, forklift reliability is absolutely intolerant of any failure.

So here is the scene: your Yale Forklift gives up during a crucial delivery window. The starter motor goes. What a prospect! You’ve got delays of operation; congested traffic at your front doorstep for the next week; potential penalties from missed SLAs. And that’s just to start with now the added cost for having to find a suitable replacement motor- I wonder how high that’ll be?

But what if you could whack that outlay by as much as 40%, though still having both good quality and lots of life left in store for your new starter motor? Welcome in short to a challenge faced by experts: how are these masses (read SMEs and network infrastructure pros) going to handle replacing parts in Yale forklifts if it means no deterioration of standards, increased exchange costs as they buy on the cheap or downtime headaches while waiting so long their customers have already moved on?

We talk here about real strategies—not generic advice. Think procurement tactics, refurbished parts sourcing and supplier vetting checklists. Be sure to adopt a budgeting process that’s risk-based: You can’t afford just to throw money at problems! We’ll also bring you some practical examples of what IT warehousing teams like yours have done, showing where they failed and what worked. This will be achieved through analysis from a technical viewpoint supported by industrial policy-making. No fluff: When dollars end, so do we.

Before You Replace, Check It Out: How to Lose $1,200

Don’t too quickly throw the blame on the starter motor if your Yale forklift won’t start. According to data in LiftTruck2012, 27% of Yale forklift starter motors that were replaced… weren’t the problem–the original fault still existed (like wiring harnesses, ignition switches and battery contacts). One IT logistics manager in Austin tells of a $1,200 loss because he swapped out the motor, only later to find that a wire had become corroded.

Pro Tip: Before you purchase a new starter motor, use a multimeter to check voltage flow at the key contacts.by You should always ask for a cost-of-ves eliminate report if your service sites are outsourced. Transparency is essential, and a reliable service shop will provide you with documents regarding shorting, fried solenoids, or mechanical jams.

Key Alert: It is not just the replacement of a Yale forklift sarter motor that matters, but getting the exact problem with your Yale forklift solved.

Leverage Aftermarket Starters—but Vet These Three Points First

By as much as 45%, alternative Yale forklift starter motors can cut your costs dramatically. But the biggest trouble with on in quality is generic import. Often, within 6-12 months these parts fail–resulting in double replacement expense.

Checklist for Vet an Aftermarket Starter Motor:

Paarranty Duration: Shoot for at least 12 months, and ideally with full load count quantities appended.

OEM Cross Reference Precision: Use aftermarket starter parts numbers checker tools to ensure a perfect fit with your Yale model (e.g., GC050VX).

Copper Coil Grades: Ask if the provider lists composition of coils inside. Cheap aluminum replacements give less torque and overheats faster on repetitive starting.It This report explains how an Illinois warehouse with computer cable inventory saved 38% by adopting the excellent secondhand brand–even if after waxing, it still had to match OEM torque specs

Refurbished Does Not Mean Risky: Rebuilding Markets Are Changing

Refurbished Yale forklift starter motors, especially in IT-based storage centers where cash outlay is limited, have greatly Ind ISIS attracted. Now rebuild options that load cycle testing includes are being offered at Hyster-Yale Certified Parts or ForkliftPartz.

Main Benefits of Refurbished Starters:

Load cycle test under environmental stress conditions. Rebuild is frequently done using OE level brushes or solenoids. Savings in prices range from 25% up to 60%.

Important: Require suppliers to use the dynamic test bench rather than just a static continuity test. Require before-and-after performance benchmarks (RPM, torque output, and draw current).

Real Data: ForkliftPartZone’s internal metrics show that refurbished starter motors have a return rate of only 4.6%, compared with the 6.3% for non certified aftermarket units.

Group Orders with Other Network Hardware Shipments

Many IT-based warehouse operations have standing orders for routers, switches or CAT 6 cable. Combining these logistics with a Yale forklift starter motor order can sharply cut shipping overheads or unlock B2B discounts.

Pro Tip: Use your company’s monthly purchasing cycles to combine parts orders. When you’re dealing with a distributor like Graybar or Anixter, you may ask for pallet-tier pricing across categories (they likewise catalogue forklift parts in their industrial supplies division).

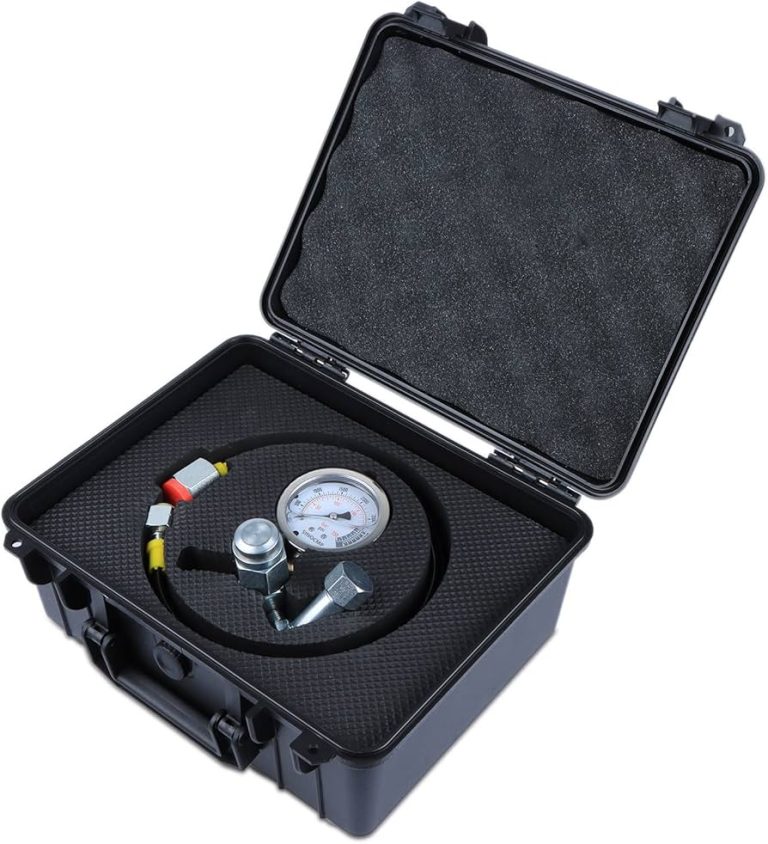

One California-based data center saved $247 in combined shipping and got a free forklift diagnostic toolkit simply by bundling buys with their Ethernet cable vendor.

Avoid Instance Service Fees: DIY Training or Mobile Solutions Works

Professional installation of a Yale forklift starter motor can run anywhere from $300-$600, depending on your geographical area. But many network-hardware-based logistics teams are taking a hybrid approach: they train internal techs for low-risk installs and only outsource big-ticket diagnostics.

Training Resources: Often starter motor replacement guides with wiring diagrams are available for free via Yale’s own tech support staff.

Uploads to internet platforms like YouTube provide full sets of visual step by tutorial on how to

Scenario: A network distribution warehouse in Denver taught a shift supervisor how to install them motors over 8 forklifts, saving $4,600 a year.

One of the supervisors at a Denver network distribution warehouse was trained to install motors across eight forklifts, saving the company $4,600 annually. It’s not just that this is a win for the bottom line, but also uptime and operational flexibility ¨C both of which are crucial in cable and hardware environments where every delivery window counts.

Benchmark starter motor life span by application load

Not all Yale forklift starter motors are created equal-or rather only a few fail at the same rate. A starter motor used in a climate-controlled laptop factory will last four years, while one subjected to dust, fluctuating temperatures and heavy use will burn out in 18 months.

The significance of this: Benchmark failure rates across your own forklift fleet, ideally segmented by locality, operating hours and load type. Construct a proactive maintenance system which tips you off about high-risk units before they fail.

Smart Strategy: Introduce a starter life-cycle tracking system into your CMMS (Computerized Maintenance Management System). Set thresholds–e.g., recommend inspection or replacement when a starter is 2,000 starts old or has been in operation for 24 months.

A case in point: By identifying high-frequency-use forklifts as in need of examination around mid-life, one East Coast logistics company that transports network switches said it reduced unexpected starter failures by 63% within a year.

Don’t ignore solenoid health: 35% of failures begin there.

Solenoids are frequently the first source of electrical failure-not the motor. A sticky or weak solenoid can fool you into thinking that your starter motor is dead, meaning that you have to replace it before its time.

Diagnosis: If your Yale forklift clicks but does not crank, isolate the solenoid circuit for testing. Often the simple change of a $45 solenoid can save you from having to spend more than $400 on a completely new starter.

Industry stat: According to LiftTech repair analytics, 35% of Yale starter motor returns were because of solenoid-related problems-not the fault of the motor core itself.

Build Relationships with Industrial Salvage Yards

Where do high-turnover forklift fleets (e.g., rental or auctioned units) end up? Shriveling away in salvage yards with often-working (and spare) components. With the right connections, you can source gently-used Yale forklift starter motors at 50-70% below market.

What to Do:

Use platforms like Ritchie Bros., Surplus Record, or directly partner with local scrap handlers.

Request photos, part numbers, and load-test data before purchase.

Inspect brush length, contact wear, and rotation resistance.

Note: Rusting pinion gears and oxidized casing turn up at the yard—avoid these signs of water damage and longtime disuse.

Negotiate SLA Clauses Around Forklift Downtime

Your IT equipment vendors won’t have service-level agreements (SLAs) that take warehouse operational delays into consideration. Add clauses representing logistical dependencies. For instance, “inventory access disruption from material handling failure” (including a forklift not starting).

Why It Matters: You can obtain additional flexibility in delivery schedules or even financial relief should delays occur from equipment breakdown. Transfer a bit of pressure (and cost) away from your operations team.

Case Example: After being told that a forklift issue was the cause of a shipment delay, a B2B cable distributor updated their SLA with a network equipment supplier. The new clause offered them a 48-hour leeway period during emergencies, thus saving them a $ 3,800 fine.

Use Data Analytics to Predict Failure Patterns

One of the most forward-thinking moves you can make is to pick sensor-based tracking for your Yale forklifts in order to monitor starter motor performance. Irregularities in voltage, cranking times, and motor heat signatures should all be reported here.

Implementation: You install telemetry-enabled modules (available from suppliers like OneCharge or EnerSys) to continuously monitor starting system behavior real-time.

Phoenix IT warehouse is a great example. They added predictive analytics to their fleet and in only six months saw starter related downtime drop 31%.

On the very last page of this report was a valuable clue. Replacement of a Yale forklift starter motor should not be a reactive task— it should be part of systemized,advice-driven procurement and maintainance model.

For pros in charge of wires and systems or local area networks, uptime of forklifts is almost as critical as uptie of mainframe computers.