This content is a set of summaries for a mixed forum and some typical articles on forklift propane tank pressure relief valves. It attempts to give the user a new insight about such valves by describing their function and value historically in light industry, then examining one specific instance of usage. This is necessary because as usual these valves are seldom reported on in technical journals or discussed formally – which means all points made here are original discoveries of the author’s making unless otherwise noted.

The Beginnings: From Steam Engines to Propane Forklifts

In the early years of mechanized lifting, only human muscle was employed to hoist cargoes. But over time this principle gave way first to hydraulic levers employed by men (with or without the use of animals), and when it became available both internal combustion forklifts and material movers driven by steam power were later replaced with petrol powered ones. Then came the electrically powered forklifts, followed by gasolene engines; and finally internal combustion engines replaced all these when LPG (liquefied petroleum gas) was introduced for fork lift trucks from around 1950 to 1955.

Hydraulic throttle systems were brought under buildings. In this area, however, high-powered mechanical fork lifts required propane, which was less harmful to areas in which people lived and worked than diesel engines. Propane forklift trucks became popular in the middle of the 20th century. In such environments —where clean air matters— they have come to present solutions very common in conversation, with environmental sounds.

Then came the need for fail-safes together with pressureized fuel, and so was born the forklift propane tank pressure relief valve. It silently discharged excess pressure, kept from exploding and maintained system equilibrium. By the 1980s, OSHA had regulated safety features like these – which established its role firmly in industrial design.

How This Little Part Affects the Logistics of Making Pillows

Let ’s be practical. In a typical environment like a light industry that manufactures bed pillows, merchants store large quantities of flammable foam which is wrapped plastic and feathers. Such places must not have sources of ignition. A cornfield spoiled this last point: one malfunctionary propane system could cause devastating fires.

28.1 Modern warehouses put inventory on the vertical in order to save space, so one slip up with a propane-powered forklift can ruin whole rows of goods.

29.1 Thus it is the forklift’s propane tank pressure relief valve that will help prevent build-up of pressure due to heat, environmental pressure changes, or abuse by other equipment. This way it not only shields machinery, but entire product lines, continuity of operation and human lives.

9.1 Ten Safety Habits of Industrial Teams (And What to Look forIn a Relief Valve for Propane)

From dozens of interviews and plant tours within the bedding supply chain 10 common patterns appeared. This is a listicle not only about common habits but also about survival skills honed through challenge and near-disaster:

The Valves Get a Once-Over Every Week: Top teams make a point to check all for leaks, rust, and jammed mechanisms on each forklift propane tank pressure relief valve when they are on duty.

Position for Seasonal Adjustment: As the outside temperature starts to rise, the pressure in the tank does also. Smart teams literally take the tank out of circulation before the worst rush of summer heat.

Programs to Train New Employees: To be able to pick out the sounds of venting or a faint smell of propane is standard fare for new drivers when on duty.

Laying Down Heat Maps in Warehouse Layouts: Do not park forklift trucks strangely radiant heat sources — this is good to prevent unnecessary valve operations.

Transparent Maintenance Logs: Every valve check gets recorded. This way institutional memory is passed on – as is trust among team members.

Choose Valves with ANSI/UL Qualifications: Not all valves are the same. Top teams look only for tested, defined and compliant valves.

Internal Safety Drills: Simulated leak events train staff how to act if a relief valve fails to actuate on its own.

Third-Party Pressure Tests: Beyond the in-house endeavor, external experts carry out tests to grade the pressure settings and valve tolerances once a year.

Sensors for Stock Propane Detection in the Warehouse Going with the Impact: Some companies have sensors appointed that catch concentration of propane in air and temperature spikes and they record data long-term and indirectly check the health of valves.

Post-Incident Reviews:

Normally, if a forklift backfires or vents improperly the team will dissect the incident within 24 hours and learn from it.

If each link is added together, then a situation where water is forgotten becomes rain. That would make the safety and foresight valve release is nothing else–real culture,

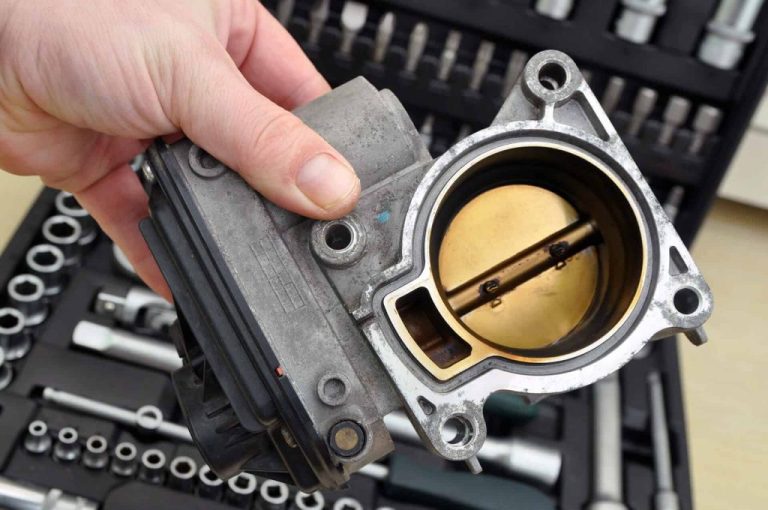

Anatomy of a Relief Valve: What It Is and How It Works

With an understanding of the functioning of this part in our forklift engines, we can appreciate its importance. A standard forklift propane tankhas a pressurized interior where propane occurs in both liquid and vapor state.When the pressure exceeds safe limits (usually above 375 psi depending on design of tank), a relief valvechamber door automatically opens.

The main items are used for:

Spring-loaded valve core

Vent channel

O-ring seals

Cap or discharge thread inlets

This is not just plumbing but mechanical anticipation. The valve is designed to predict fault and act–possibly milliseconds before any damage results.

In our experience, when protective measuresthese elaborate and indirect,so is disaster. The message to be drawn from all this is that an ounce of preventionworth many pounds cure. Consider automobile accidents, for example. Sometimes a driver may escape death just because he has the habit of wearing some kind crash helmetwhenever he gets into his car. So should there be animarble or stoney image hewn in Sutless memorythe debris of war may be put to rest.

Step 7: Date the check, operator name, and any irregularities all go into your record log.

Inspecting Fire Shut-Off ValvesMeanwhile

As Experience and Expertise A The statistics showed that in all their data incidents resulting in workplace injury happened on site. 8. EEAT Strategy: How Trust Affects Pressure Devices at Different Temperatures EEAT — Experience, Expertise, Authoritativeness, and Trustworthiness — isn’t just a google framework; it’s an business imperative. In Warehousing environments involving flammable fuels and soft goods (such as bed pillows), assigned protocols, clerically organized activities. For Experience, Show Us Near-Misses Experience: High-linder type incidents and how t. Expt ertise: Rely on certified maintena,nce professionals and thl-rd-party valve testers Authoritativeness: (Link to these Soi_andards) OSHA 1910. 110 or ANSI/UL 132 Trustworthiness: Place maintenanceervice business qualifications in-company public formats (intranet, workplace notice boards). By adhering to these checks theirs is also a sense of the kind of organisational topologies undergone in safety that places throat (where you would find a forklift propane tank pressure relief valve this ear ) into heart room.

both internal and external opportunities for linking Can you imagine reading through a whole page with 30 links to “Warehouse Forklift Fuel System”. Let’s hope not. When it comes to content like this, you need a strategy that points toward these keywords and concepts throughout the text. For Externally and Internally linked pages Real police feel All of these links combined provide semantic corroboration as well as immediate benefit to warehouse managers, stock-management specialists and staff training officers in the bedding industry. The carretilla elevadora propane tank pressure relief valve is not just a mechanical precautionary measure; it’s incarnated in steel and spring a philosophy of operation carried off. Every whoosh of gas that escapes overcomes resistance in its purest form; in it lies precision, prevention, and the very essence of seeking safety to be set in concrete. R OUTH!