Contenido

- 1 Hydraulic Lift Pump in Lifting Equipment: Core Role in Load Capacity and Stability

- 2 How to Choose the Right Hydraulic Lift Pump for High-Temp, High-Dust Sites

- 2.1 1. Heat? No Sweat.

- 2.2 2. Dust Proof or Bust

- 2.3 3. Hydraulic Oil Matters

- 2.4 Single-Stage vs. Multi-Stage Hydraulic Pumps: Efficiency, Maintenance, and Real-World Fit

- 2.5 Playing by the Rules: CE & ATEX Compliance for Hydraulic Lift Pump Installation

- 2.6 Real-world nightmares—how one pump survived (and another died) in Australia’s dust bowl.

- 3 War Stories from the Outback: When Hydraulic Lift Pumps Meet Australian Dust Hell

Hydraulic Lift Pump in Lifting Equipment: Core Role in Load Capacity and Stability

Let’s cut to the chase—if you’re working with lifting equipment, the Hydraulic Lift Pump isn’t just another component; it’s the heart of your system. Picture this: a 20-ton load suspended mid-air, and the only thing between smooth operation and a catastrophic failure is your pump’s ability to maintain pressure. That’s why understanding its technical guts matters.

What Does a Hydraulic Lift Pump Do?

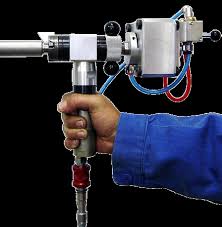

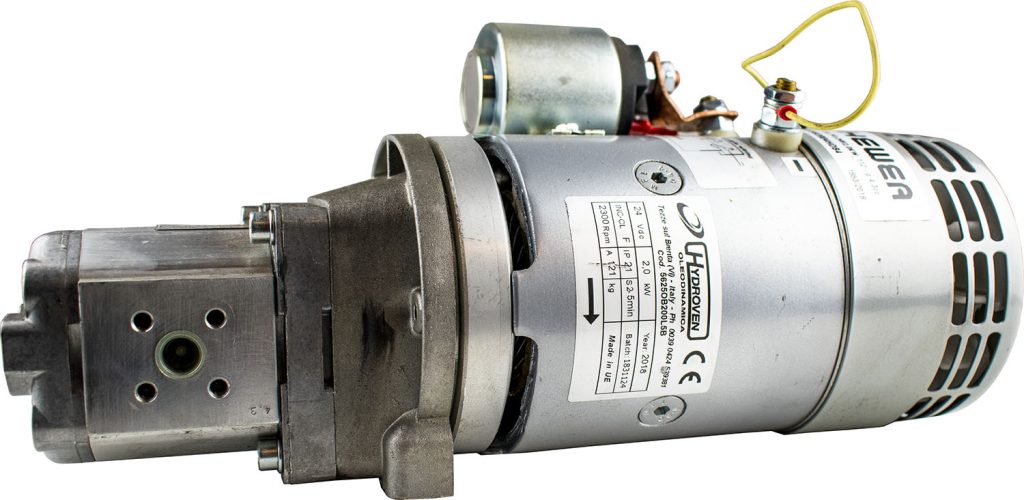

Here’s the deal: Hydraulic Lift Pumps convert mechanical energy into hydraulic energy, pushing high-pressure hydraulic oil through your system to lift heavy loads. The carbon steel construction? Non-negotiable. It’s what gives the pump its brute strength to handle DN100 high-pressure flows without buckling.

And let’s talk about the smart linkage—manual control for precision, paired with Modbus-enabled automation for when you need to sync with PLC systems.

Why Stability Is Non-Negotiable

But here’s the kicker: stability isn’t optional. A leaky seal or pressure drop in your hydraulic oil line can turn a routine lift into a OSHA report. That’s why features like SIL2-rated safety seals y bolt-fixed flanges aren’t just specs; they’re your insurance policy.

Real-World Consideration: Harsh Environments

How to pick the right pump when your job site feels like the Australian Outback—dust, heat, and all.

How to Choose the Right Hydraulic Lift Pump for High-Temp, High-Dust Sites

Alright, let’s get real—construction sites in places like Australia’s Pilbara region aren’t just tough on workers; they’re brutal on equipment. If your Hydraulic Lift Pump can’t handle 50°C heat and dust storms, it’s just a fancy paperweight. Here’s how to pick a warrior, not a weak link.

1. Heat? No Sweat.

High temps thin out hydraulic oil, killing pump efficiency. Look for:

- Built-in cooling jackets or oil temp sensors (bonus if it ties into your Modbus remote control system).

- Carbon steel bodies—they dissipate heat better than cast iron when things get spicy.

2. Dust Proof or Bust

Dust = abrasive death for seals. Your pump needs:

- IP66-rated seals (CE certification minimum).

- Inline filtration—because no one has time to disassemble a pump clogged with red dirt.

3. Hydraulic Oil Matters

- High-Viscosity Index (VI) oils—they won’t turn to water in the heat.

- Compatibility with your pump’s elastomers (check the manual—cheap oils eat seals).

Pro Tip: Opt for online maintenance designs—you don’t want to dismantle the whole rig just to replace a gasket when it’s 45°C outside.

Single-Stage vs. Multi-Stage Hydraulic Pumps: Efficiency, Maintenance, and Real-World Fit

Time to settle the debate—do you really need a multi-stage pump for your lifting equipment, or is a single-stage workhorse the smarter play? Let’s break it down like a mechanic at 2 AM.

Single-Stage Pumps: The Rugged Simplifiers

- How They Work: One piston, one massive push. These are the muscle cars of pumps—simple, powerful, and fewer parts to fail.

- Best For: High-flow, lower-pressure apps (think rapid lifts under 3000 PSI). Perfect for DN100 systems where speed beats finesse.

- Maintenance Win: Fewer seals, fewer leaks. If your site’s mantra is “fix it fast and get back to work,” this is your pump.

Multi-Stage Pumps: The Precision Overkill?

- How They Work: Multiple pistons working in sequence for ultra-high pressure (we’re talking 10,000 PSI+). Great for precision lifts… if you need it.

- The Catch: More stages = more seals, valves, and failure points. That “smart linkage” system? It’ll cost you triple in downtime if dust gums up the works.

- Reality Check: Unless you’re lifting bridge girders millimeter by millimeter, a single-stage with a SIL2-rated safety valve often does the job cheaper.

- Efficiency Myth: Multi-stage pumps look efficient on paper, but in a high-dust Australian mine, 30% of their “efficiency” vanishes keeping contaminants out of those tight tolerances.

Playing by the Rules: CE & ATEX Compliance for Hydraulic Lift Pump Installation

Let’s be honest—nobody reads compliance manuals for fun. But when inspectors show up on your jobsite, “I didn’t know” won’t cut it. Here’s the no-nonsense guide to installing your Hydraulic Lift Pump without getting slapped with fines or worse.

1. CE Certification – Your Legal Bare Minimum

- Pressure Directive 2014/68/EU: Your DN100 pump handling 300+ bar? It must have CE marking proving it won’t explode like a grenade. Check for:

- PED Category IV stamp (for high-pressure systems)

- EN ISO 4413 hydraulic compliance (prevents “surprise” hydraulic oil showers)

2. ATEX Zone 2? Don’t Skip This

Working near flammable dust (hello, Australian grain silos)? Your pump needs:

- Non-sparking carbon steel construction (standard carbon steel can’t cut it)

- Certificado ATEX solenoid valves if using smart linkage controls (a Modbus spark in dusty air = bad news)

3. Installation Landmines

- Bolt torque matters: Under-tightened flange connections leak; over-tightened ones crack. Follow EN 1092-2 specs to the Newton-meter.

- Grounding is life: Static buildup in hydraulic oil lines can ignite dust. Use braided hoses with proper earthing (IEC 60079-14 isn’t optional).

Pro Tip: Keep the CE Declaration of Conformity in your rig’s glovebox—inspectors love paperwork more than your accountant does.

Real-world nightmares—how one pump survived (and another died) in Australia’s dust bowl.

War Stories from the Outback: When Hydraulic Lift Pumps Meet Australian Dust Hell

You want theory? Read a textbook. You want truth? Here’s what really happens when Hydraulic Lift Pumps face Australia’s mining country – where red dust eats equipment for breakfast.

Case 1: The Survivor (Carbon Steel + Smart Design Wins)

Location: Iron ore mine in Western Australia (ambient temp: 48°C, dust levels “like a Mars simulator”)

Pump Specs: DN100 single-stage, carbon steel body, IP66-rated seals, online maintenance ports

The Win:

- Crew replaced filters via quick-release panels without full disassembly (took 20 mins vs. 4 hours)

- Modbus alerts flagged oil viscosity drops before overheating – saved $15k in bearing replacements

Case 2: The Failure (When Cheap Becomes Expensive)

“Budget” Pump: Multi-stage, cast iron, “dust-resistant” (spoiler: it wasn’t)

How It Died:

- Dust infiltrated precision piston chambers – within 3 weeks, pressure dropped 40%

- No SIL2 safety override – kept running until seals blew hydraulic oil across half the site ($50k cleanup)

The Lesson: That extra 5% cost for CE/ATEX-rated pumps? It’s cheaper than explaining to your boss why the project’s now 3 weeks behind.

3 Dirty Secrets to Extend Your Hydraulic Lift Pump’s Life (Without Hiring More Crew)

Newsflash: Pumps don’t die—they’re murdered by lazy maintenance. Here’s how the pros keep Hydraulic Lift Pumps running like they’ve got a second life, even in hellish job sites.

1. The “Oil Autopsy” (Every 250 Hours)

- Don’t just check levels—read the oil’s story:

- Gold/copper flakes? Bearings are staging a mutiny.

- Milky texture? Water intrusion (common in humid coastal sites).

- Pro Move: Use $5 magnet plugs on drain ports—they catch ferrous debris before it grenades your pump.

2. Bolt Check Rituals (After First 50 Hours, Then Quarterly)

- Loose flange bolts cause 60% of leaks in DN100 systems.

- Torque sequence matters: Follow the star pattern (like lug nuts) to avoid warping.

- Cheater Trick: Mark bolts with paint pens—a glance tells you if they’ve shifted.

3. Modbus Hacks for Lazy Geniuses

- Set PLC alerts for:

- Pressure spikes = clogged filter (change before it bursts)

- Temperature ramps = cooling jacket failure (fix it during lunch break)

- Real-World Example: A Queensland mine added vibration sensors—caught impeller imbalance before it torched the shaft ($8k saved).

Bonus: Annual “Dumb Mode” Test – Disable smart systems, run manual. If performance drops, your electronics are hiding mechanical sins.

Hydraulic Lift Pump FAQs – The No-BS Answers You Actually Need

Time to tackle the questions that keep construction crews arguing at the job site trailer. Here’s the straight talk—no marketing fluff.

1. “Smart Controls vs. Manual – Worth the Extra $$$?”

- Manual Pros: Cheap, reliable, no programming headaches.

- Smart Pros: Modbus + PLC integration gives you real-time pressure alerts, predictive maintenance, and remote diagnostics.

- The Verdict: If your crew forgets to check oil levels, go smart. For small sites? Save the cash.

2. “Why Does My Pump Lose Pressure After 6 Months?”

- Top Culprits:

- Worn piston seals (especially with cheap hydraulic oil)

- Clogged inlet filters (dust builds up silently)

- Fix: Install magnetic pre-filters and use high-VI oil.

3. “Can I Use Any Hydraulic Oil?”

- Short Answer: Hell no.

- Long Answer: Cheap oils foam in heat, thin out, and destroy seals. Stick to ISO VG 68 o AW-32 for most DN100 pumps.

4. “How Often Should I Really Replace Seals?”

- Rule of Thumb: Every 2 years or 10,000 operating hours—whichever comes first.

- Exception: In Australian dust storms? Inspect every 500 hours.

5. “What’s the One Upgrade That Actually Matters?”

- Hands Down: Online maintenance ports. Cutting downtime from 4 hours to 20 minutes pays for itself in a week.

Final Thought: A pump is only as good as the idiot… er, professional maintaining it.

Links:http://m.cyhzf.com/konecranes-hydraulic-lift-pump-6022-039-p2075s3773/