“What? Do you mean that due to some startup failure your fork lifts are out of service again?”Riku said and turned around to frown at the long table of management. A cross-cultural team is sharing one screen, all transfixed on a single string of order delays from the Midwest involving a big fishing tackle supplier. “We are dealing with more than just machines here,”Maria added, an operations lead from Buenos Aires.

Logistics are high-stakes in the recreation supply world– especially with fishing tackle. Whether you ‘re unloading carbon-fiber rods or unch bin jig heads, every second and penny counts. At the center of this uptime sits a small but mighty component: a Clark forklift starter motor.

Understanding the Clark Forklift Starter Motor

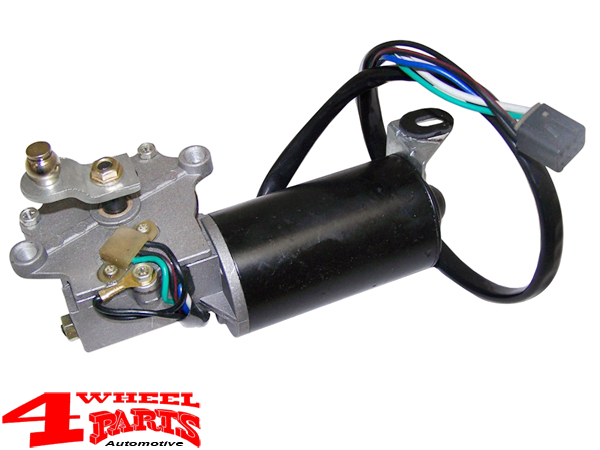

A Clark forklift starter motor is not simply a component; it ‘s the pulse of ignition that puts your heavy-lifting machinery in gear. This crucial mechanism transforms electrical energy down through mechanical rotation and establishes the cycle of combustion in internal-combustion forklifts.

When the starter fails, downtime follows. For many of those operating in branches such as recreation supplies and fishing gear distribution–where timing and seasonality can either force higher margins or drive them down so low that they sink into irretrievable bankruptcies–such stoppages aren’t just an inconvenience: they’re devastating financially too.

“We missed an entire worldwide bass tournament supply opportunity once because two forklifts wouldn’t go. Both were using Clark motors. If we had known how to replace starters like that, we could have avoided this,”says Jacob, a warehouse manager at a Louisiana coastal fishing gear supplier.

Learn herein how to get the most out of your motor and get to grips with it in terms of both installation and maintenance.Why the Fishing Tackle Supply Chain Relies on Clark Forklifts

The fishing tackle industry might seem like a niche market, but globally it’s worth billions and billions. Consequently most of the major warehousing facilities in this field use Clark forklifts of medium-size or larger.

How much can the Clark forklift starter motor really take? In this article, we take a look at two machines and one famous video forklift in action. There are other factors to consider as well: how many spare parts are available during the life of the forklift (especially when comparing different models) and whether or not compatibility is possible with custom warehouse systems. Two years ago Jason had been on holiday in Shenzhen, where he saw 20 loaded pallets going up off a factory floor area under his feet. We’re talking about stacks up to ten high here!! And this wasn’t even a large stack – it was just one of hundreds that make up the seemingly endless warehouses in this city on China’s southeast coast.

Availability of spare parts is an important specification, including how many times in a year the starter motor for a Clark forklift should be replaced. Compatibility with customized warehouse shelving systems can also determine whether logistics and forklift uptime are a big or small problem.

How do you get a torpedo boat up on the wharf? If it decided to torpedo surf across 50 miles of Pacific Ocean to meet us, would it make it? And exactly how far in would travel before eating us?

One of the costliest contributions to downtime for any forklift fleet is simply work that can’t be carried out. From live bait fridges to reel stacking pallets, precise handling doesn’t leave room for even short-term failure.

How to: Pre-Installation Checklist for Clark Forklift Starter MotorBefore installation, make sure these boxes are ticked:

Battery Voltage Match

Designed for specific voltages (12V or 24V), the Clark forklift starter motor must not be used at the wrong voltage. Doing so can either burn out the solenoid and/or make it fail to engage the pinion gear.

Inspect Electrical Connections

It is essential for terminals to be clean and cables free of corrosion. Forklift operators often neglect these two essentials, but even 0.5 ohm resistance can stall startup.

Check Flywheel Teeth

Worn flywheels can grind the starter’s pinion, leading to premature failure of the motor. Always check the tooth alignment and wear.

Verify Model Compatibility

Cross-reference part numbers with Clark’s official starter motor guides or use a VIN decoder for exact matching.

Test the Old Unit

A bench test using a jump starter can determine whether replacement is actually necessary. Some faults are wiring-related, not motor faults.

Step by Step: Installing a Clark Forklift Starter MotorTools Required:

14mm socket wrench

Torque wrench able to measure up to 50 lb.ft total

Dielectric grease

Loctite Blue (for bolt thread)Step 1: Disconnect the Battery

Always remove the strong link of the lead out of circuit first. No sparks or shorts all round—please.

Step 2: Remove Old Motor

Unbolt the old motor from the engine block. Then attach masking tape labels to wires so as to avoid confusion later on.

Step 3: Prepare New Motor

Apply Loctite to the bolt threads. Be sure that the pinion gear freewheels easily and is not jammed from shipping.

Step 4: Installation and tightening

Connect the generator and screw in bolts to torque recommended by the manufacturer (methods usually include 35-45 lbs-ft). Avoid over-tightening, which can crack the casting.

Step 5: Re-insert the Wires

Make sure plugs and plate are all properly connected together with no play at all. Use dielectric grease to keep moisture out of them.

Step 6: Test the Starting Motor

Turn the key, monitor the sound—a smooth cranking. A high-pitched whir is a sign of misalignment or weak power feed.

Why Your Team Needs Physical Experience

Warehouse staff cross-trained on shore motor repair has particularly high ROI. According to a 2023 study by RecSupplyTech, tackle suppliers with teams trained through workshops had twenty-seven percent lower downtime in six months than vendors who depended solely on outside mechanics.

“Simply by teaching our team to recognize and replace Clark forklift starter motors we cut maintenance costs $3,800. It’s a course for everybody at our onboarding,” Sabrina says.

“We cut our annual maintenance fee by $3,800 simply because we let everyone know how to identify and exchange Clark forklift starter motors. It is now part of our induction.”, says Sabrina the Seattle angling wholesaler.

This level of self-reliance can do more than save money–it builds operational resilience; and in the case of sporting goods, where product life cycles are seasonal and profits margins thin to non-existent, having in-house expertise on rudimentaries like starting machines is a strategic advantage.

Common Issues with Clark Forklift Starter Motors–and How They Can Be Avoided

Even high quality components like the Clark forklift starter motor can break down. Here’s how most operators tend to go wrong–and three ways you can stay ahead of the problem:

Heat Soak from Nearby Exhaust Manifolds

In poorly-ventilated forklifts, lingering engine heat can cause wear on the starter solenoid. If there are repeated failures then use heat shields, or better still reroute manifolds altogether.

Short Cycling the Ignition

Repeatedly turning the key without giving the starter an opportunity to rest strains its solenoid coil. Always wait for 5 to 10 seconds between crank attempts–every time.

Loose Mounting Bolts

In a vibrating motor wear inside occurs rapidly. Torque check every 3 months is a preventive necessity.

Corrosion in Humid Environments

Salt air warehouses (especially by coastal tackle suppliers) corrode terminals fast. Apply anti-oxidation paste every quarter.

Case Insight: A Miami fishing distributor noticed a 70% reduction in forklift starter failures after incorporating regular terminal cleaning into their monthly PM list.

Choosing the Right Clark Forklift Starter Motor: Specs That Matter

Not all Clark starters are made the same. For boating tackle operations considerations include:

Torque Rating: Heavier loads or dock slopes uphill? Look for starters with high initial torque.

Brush Type: Carbon brushes last longer than copper in start-stop environments like those wharves have become. Copper brushes wear out higher amperage than their carbon counterparts.

Solenoid Position: Some manufacturing model aftermarket units don’t have the same solenoid placements as original equipment manufacturers–resulting in bad wiring and eventual burnout.

A recommended starter for most C500 series Clark forklifts used in deep sea tackle depots:

Model: CLK-START-XHD24V — 24V, sealed solenoid, corrosion-free shell.

External Resources and Link Building Suggestions

In addition to furthering understanding or procuring durable parts from reputable sources:

Clark Material Handling Official Site

Fishing Tackle Retailer Logistics Guide

Aftermarket Clark Forklift Starter Motor Cross-Reference Table — PDF from LiftParts HQ

Internal content linking ideas:

“How to Maintain Forklift Batteries in High-Humidity Environments”

“Best Pallet Racking Systems for Fishing Tackle Distribution Centers”

“Reducing Downtime in Seasonal Warehousing: Tools That Matter”

Final Note: Building Confidence One Starter at a Time

At every point in the fishing tackle supply chain–from seasonal ups and coastal humidity to variable loads per bay–a modest Clark forklift starter motor is an unexpectedly strategic component. In warehouses from Buenos Aires to Boston that take great care with both the assembly and proactive maintenance of this part have reported genuine performance improvements.

Investing in knowledge, standardizing best practices, and empowering your teams can turn a starter motor–once a voiceless point of failure–into a symbol of automotive preparedness and uninterrupted business continuity.

!