Contents

- 1 Electric Motor Forklifts Powering the Hardware Industry

- 1.1 Hidden Motor for Warehouse Productivity

- 1.2 Why Electric Forklifts—Powered by an Electric Motor

- 1.3 A Revolution

- 1.4 Lower the Burden of Ownership Costs

- 1.5 A Clean Operation Equals a Higher Level of Compliance

- 1.6 Electric Forklift Motors: Strategic Workflow Integration

- 1.7 Step 1: Audit Your Current Material Handling System

- 1.8 Step 2: Select the Appropriate Motor Group

- 1.9 Step 3: Time Your Charging Stations with Periods of Real Machine Inactivity

- 1.10 Why Should You Choose a Nissan Forklift Motor?

- 1.11 However All Nissan Forklift Motors: Problems

- 1.12 Motor Overheating

- 1.13 Quick Fix

- 1.14 Starting a Car That Won’t Start

- 1.15 Quick Fix

- 1.16 Reduction of Lifting Power

- 1.17 Minor Workaround in a Stroke

- 1.18 Strange Sound

- 1.19 Temporary Measure

- 2 How To Better Maintain Your Nissan Forklift Electric Motor

Electric Motor Forklifts Powering the Hardware Industry

Electric motor forklifts are quietly taking over the logistics backbone of tool and hardware industries–especially in diamond tools and hardware accessories operations. Where every smooth-loading bay or organized warehouse manager-guarded nestles: the electric forklift motor at work. You may think this is just another link in a chain but in reality, it’s actually the unsung hero driving efficiency, cost control and sustainable business growth.

Hidden Motor for Warehouse Productivity

Imagine a manager named Laura. She runs an Ohio-based, mid-sized diamond tools operation. She recently switched all diesel forklifts to electric models. Within three months, her operating costs had fallen by 18%. Downtime was down 30% from its former dizzy heights and output volumes were rising fast without any mechanical breakdowns. What made the biggest difference? The top quality electric forklift motors she bought.

That’s not just Laura’s story–it is increasingly popular. However, many people in tools and hardware production still overlook the impact that electric forklift motors can have. If you’re responsible for a hardware accessories distribution center or in charge of the supply chain for industrial tools, understanding how these motors fit into your work–and buying, fitting them properly–is no longer a choice.

Why Electric Forklifts—Powered by an Electric Motor

A Revolution

Shipping in narrow lanes with crowds of shelves on either hand is an environment typical of the hardware accessories trade. Conventional fuel forklifts are incapable of offering the precision control which electric forklift motors provide. This precision controls will minimize damage to commodities: highly valuable diamond tools.

Lower the Burden of Ownership Costs

Huh? A little higher at first. Down in the long run? A lot! Electric forklift motors save thousands of dollars for companies that have fewer moving parts, consume no fuel, and are less maintenance-intensive every year.

There is a 27% TCO reduction in the first year, according to a 2023 case study by the Material Handling Institute of hardware warehouses which use electric models.

A Clean Operation Equals a Higher Level of Compliance

OSHA and EPA enforcement is getting tighter over emissions, especially in enclosed warehouse spaces. Electric motors eliminate all emissions thus make it easier to comply with regulations while providing a healthier work environment–without compromising power.

Electric Forklift Motors: Strategic Workflow Integration

Simply knowing the value of electric forklift motors is not enough. The real question is: how do you incorporate them into your current workflow so that it can be maximized for ROI?

Step 1: Audit Your Current Material Handling System

Begin with a systems audit:

How many forklifts do you now have?

What fuel are they currently using?

How much do you spend on average for maintenance and downtime?

What are the load patterns (weights, shift cycles, terrain)?

Example: A San Diego hardware parts supplier found that two of its combustion forklifts were spending 20% of operating hours idle. By deploying electric motors with their duty cycles optimized, it was able to reduce idle time radically, down to under 4%.

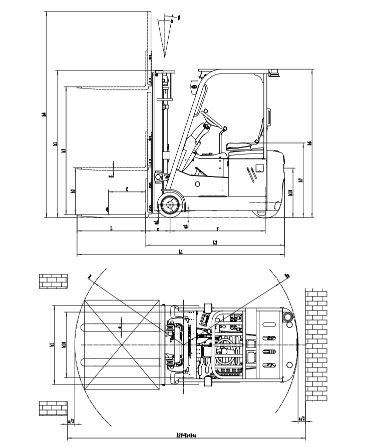

Step 2: Select the Appropriate Motor Group

Electric forklift motors don’t all come the same. Key factors are:

Voltage (24V – 80V): More volts for heavier loads.

AC vs. DC motors: AC packs greater torque and less maintenance.

Brushless vs Brush: Brushless motors last longer and require less maintenance.

Step 3: Time Your Charging Stations with Periods of Real Machine Inactivity

Idle time is the devil. Savvy warehouses have lithium-ion-powered fork lifts with recharging cycles coincide during lunches or on the night shift. Plan your charging cycles = uninterrupted workflow.

Nissan Forklift Engine in Construction and Flooring Industries

No matter what products are being shifted, the forklift engine, if functioning smoothly, is a key player in the daily operation of industries such as construction and flooring.

For most businesses the most obvious choice, however, is a Nissan forklift engine; reliable and high performance. But how do you ensure that your Nissan forklift engine gets the greatest benefit use and value for money out of it? What are common problems that users run into, and what is to be done about these? This article answers these questions from beginning to end. It is specifically for those in the construction and flooring business.

Nissan forklifts represent robustness and efficiency in the field of materials handling. This makes a big difference in whether you work out in the field of construction and installation or are in industry, as well as practicing your trade. This guide will describe in great depth what advantages there are in using a Nissan forklift motor; it will also give a detailed analysis of what kind of problems new users are apt to run into and how to sort them out so everyone can enjoy the maximum efficiency from these outstanding motors.

Why Should You Choose a Nissan Forklift Motor?

For quite a long period of time, Nissan has been at the forefront of the forklift industry. They make many different types of motors for all kinds of industrial applications. In projects — especially construction projects and flooring work — their forklifts have gained a good name because they can hold up under load and work energetically. But why is the Nissan forklift motor your best choice?

In terms of reliability, Nissan forklift engines are often associated with long service lives. They are designed to withstand the harsh environment that exists on construction sites or when working all day on floor tile jobs. Improper maintenance will only return nothing but headache and trouble after time. Consequently, you must pay attention in order to get several good years of use from them.

Efficient: High performance–for these engines, designed by efficiency leaders and upheld as. If you are in any construction or flooring business and one constant fact is cost control, Nissan forklifts help to heterodyne wave energy waste over an entire business scope.

Ease of Maintenance: Nissan forklifts are known for their user-friendly maintenance schedules. With easy access to individual components and some sensible designs that are not so small, it tends to be somewhat easier to service these engines than it is for other types of motor models.

Versatility: Nissan forklifts offer a wide selection of models to meet all needs of enterprise. Whether you require a motor for indoor or outdoor use–Nissan forklift motors manufacture some type that’s sure to fill the bill.

However All Nissan Forklift Motors: Problems

Although in general Nissan forklifts are reliable, like any other item of mechanical equipment their motors can develop problems as time goes on. It helps a lot if you know the common problems your Nissan motor might have. With no wasted time at all, this will make it possible for you to correct them in an hour or less and thus save your machine some wear and tear.

Motor Overheating

Motor overheating is one commonplace problem; especially if the forklift has been working for a long period without a break. Overheating will harm motor performance and can lead to complete failure in the worst case. If you’ve got a Nissan forklift motor overheating on your hands, the most important thing to do is to check all necessary coolant levels are at their correct point of manufacture, as well as having clear ventilation holes and finally check the engine cooling system functionality and efficiency.

Quick Fix

To deal with the overheating of the motor, first of all search out and remove any blockers in the air flow path around it. Also it’s a good idea to check regularly, for example during a return check from retirement (ex-service), that unpressurised continuous service systems run well. And ensure that air circulates through the core like compressors (specifically when they’re running).

Starting a Car That Won’t Start

Common problems experienced by users of Nissan forklift motors is that it won’t start at all. This could be due to bad wiring issues, a dead battery, or wear on the starter motor units. When you’re in a hurry to transport materials to some place quickly and efficiently, this is the kind of trouble none of us can afford.

Quick Fix

Start at looking over both the battery voltage and starter motor condition. Replace any part that has worn out including cables or connections. Regularly check and clean your terminal jacks and you will have good starting power.

Reduction of Lifting Power

The electric stacker in our warehouse can still drive, but it has a lower weight capacity. If too much is picked up with this truck or the system starts to collapse completely under even light loads on ramps that make normal driving impossible, then eventually there will be an unfortunate accident due to wear and tear behavior.

Minor Workaround in a Stroke

First, check the hydraulic system for low fluid levels or leaks. For instance, if the fluid is already dirty, drain it and replace with correct type of new one. Make certain that the level at which to fill-up is normal. If things still do not get better, then repair or replace the system pump as required.

Strange Sound

Pretty much any out of the ordinary noise that engine makes at all, is saying you have a problem. A grinding, squeaking sound or rough vibrating ripple in another direction reminds people that they should look under the hood occasionally for greater rapidity of parts wear out even when they cannot hear them.

Temporary Measure

Apply lubrication to parts that are in motion so as to reduce the onset of friction with resultant wear and tear. If the problem still exists, check to see if any motoring parts such as bearings and rocker arms may be damaged.

How To Better Maintain Your Nissan Forklift Electric Motor

Focus not only on resolving common problems of your Nissan forklift motor but follow a long-range strategy guiding its maximum performance. Here’s how it’s done.

Regular and Scheduled Maintenance

Regular and scheduled maintenance for your forklift is as vital as it is feasible. Gently use the vehicle often and regularly check it over for signs of wear and tear. You will detect small problems before they become expensive repair bills in this way.

Getting Trained Aright

To have the operator for your forklift truck trained correctly means that it will be used exactly as designed without fear of misuse leading to engine damage.

Only Use Genuine Nissan Components

Whenever your engine needs parts replacement, be sure to use authentic Nissan parts. Though generic parts from the current aftermarket are cheaper, they are not necessarily manufactured under as high a standard of quality. You may be sacrificing some of the performance and life span of your forklift motor.

Understand Maximum Load Limitations

Overloading a forklift engine inflicts unnecessary stress on it and could shorten its working life. Always keep in mind the manufacturer recommended maximum load limits to prevent overloading the engine.

Choosing the Right Engine for Your Business

Choosing the proper forklift engine for your business is basic to maintaining efficiency of construction or carpeting. Analyze closely the specifics of your unique operation, including the types of material you handle, your working environment and the quantities of material to be moved.

Because of its power, efficiency and reliability, many companies favor Nissan forklift engines. By adhering to these tips and optimizing the performance of their forklift motors, your business can run smoothly and effectively.