Contents

- 1

- 1.1 Why the Seatbelt Sensor Matters in Toyota Forklifts — And When It Doesn’t

- 1.2 Top 7 Use Cases Where Disabling the Toyota Forklift Seatbelt Sensor Makes Strategic Sense

- 1.3 Step-by-Step: How to Disable Seatbelt Sensor Toyota Forklift (Safely)

- 1.4 Legal Gray Area? Here’s What OSHA, Toyota & Industry Peers Say

- 1.5 How This Applies to Flag & Banner Production Floors

- 1.6 Pro Conversion Strategy: Combine Sensor Mod with Workflow Planning

- 1.7 Reducing Workflow Friction: Human-Centric Forklift Use

- 1.8 Internal Safety Audits: Your Post-Modification Safeguard

- 1.9 Future-Proofing: Alternatives to Disabling the Sensor

- 1.10 Common Mistakes to Avoid When Disabling Seatbelt Sensors

- 1.11 External Resources to Reference or Link

- 1.12 Final Thoughts: Disabling the Seatbelt Sensor Isn’t About Breaking Rules — It’s About Setting Smarter Ones

Disable seatbelt sensor Toyota forklift — this phrase might seem like a niche technical concern, but for many in the Arts & Crafts, Gifts & Decoration, and Flag & Banner sectors, it’s an everyday operational dilemma. Whether you’re managing small-batch production or handling seasonal bulk logistics, Toyota forklifts play a crucial role in your workflow. But when safety systems like seatbelt sensors get in the way of practical tasks — especially during non-standard loads or stationary operations — confusion and inefficiency follow.

Let’s be clear: disabling any safety mechanism must be approached with care, compliance, and a full understanding of the implications. This article doesn’t just tell you how to disable seatbelt sensor Toyota forklift — it goes deeper into why, when, and how to do it responsibly, particularly tailored for businesses in the visual, creative, and gift-driven industries.

Why the Seatbelt Sensor Matters in Toyota Forklifts — And When It Doesn’t

Seatbelt sensors are designed to ensure the operator is securely strapped before engaging the machine. In typical warehousing or construction environments, that’s non-negotiable. But in more nuanced workspaces — say, when positioning large hand-sewn banners on a racking system, or gently maneuvering delicate ceramic gift items — forklifts are often used in slow, precise movements where seatbelt restrictions hinder more than help.

“In our workshop, we often adjust stock by inches — not feet,” says Chloe Han, logistics manager at a boutique holiday décor studio in Illinois. “The seatbelt alarm would interrupt every single micro-move.”

If your operator is working in a stationary position for long durations — lifting with attachments, moving slowly inside creative spaces — the seatbelt sensor may be more of a nuisance than a safety net. That’s where a smarter, context-aware approach comes in.

Top 7 Use Cases Where Disabling the Toyota Forklift Seatbelt Sensor Makes Strategic Sense

If you’re considering disabling the seatbelt sensor, ensure it’s for reasons that improve process efficiency without compromising safety or violating OSHA regulations. Here are seven real-world use cases from within the Gifts & Decorations and Arts & Crafts industries:

Stationary Packing Assistance

Forklift used as a platform while staff packages banners.

Photo Shoot Backdrops Setup

Forklift used indoors with artistic structures.

Laser-Cut Display Item Positioning

Where repeated mounting/dismounting delays timelines.

Seasonal Product Staging

High volume of non-heavy items, slow indoor movement.

Art Gallery Load-in/Load-out

High sensitivity materials, extreme caution required.

Flag Storage Reorganization

Work done over hours with minimal movement.

Forklift Used as Elevated Work Platform

Only allowed with correct platform and cage, but seatbelt sensor may trigger despite safety precautions.

In all these cases, operators report increased downtime, workflow disruptions, and even sensor failure from overuse. Still, a solution must be technical, traceable, and mindful of liability.

Step-by-Step: How to Disable Seatbelt Sensor Toyota Forklift (Safely)

Before you touch a wire or unplug a switch, understand: improper handling can void warranties, lead to mechanical errors, or — worst — cause injury. This is not a job for trial-and-error. That said, here’s a professionally vetted walkthrough for educational purposes only:

Turn off the forklift and disconnect the battery.

Always ensure there’s zero current running through the system.

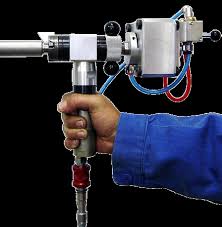

Locate the seatbelt sensor wiring.

Usually found under the seat — check the operator’s manual for your model (e.g., Toyota 8FGCU25).

Identify the switch or connection port.

Most are simple two-wire connectors that signal “belt buckled.”

Use a jumper plug or loop wire.

This tricks the system into thinking the belt is always fastened.

Secure the wiring and cover.

Prevent exposure to moisture or interference.

Reconnect the battery and run diagnostics.

Make sure no dashboard errors appear.

Log the change in your equipment maintenance records.

Keep a record in case of audit or accident review.

?? Tip: Use removable modifications (like jumper adapters) so the original functionality can be restored quickly if needed.

Legal Gray Area? Here’s What OSHA, Toyota & Industry Peers Say

There’s no specific OSHA mandate that makes disabling a seatbelt sensor illegal — but operators must still wear seatbelts if the forklift is in motion. Toyota’s official stance is against modification of safety features, yet some models lack software-based enforcement anyway. So what’s the real-world approach?

Mitigate with training: Require operators to know when seatbelts are required, and how to override sensors only for valid reasons.

Add signage on modified machines: Label the forklift clearly: “Modified Sensor – Belt Use Still Required.”

Audit usage: Log the hours when seatbelt sensors are bypassed, and pair with location-based reasoning (e.g., indoor staging bay).

Case example: One decorative lighting warehouse in Kansas disabled sensors on only 2 out of 15 forklifts, strictly reserved for indoor work under 1 mph. They saw a 17% increase in efficiency during pre-Christmas volume spikes — and zero safety incidents.

How This Applies to Flag & Banner Production Floors

In the banner-printing segment, forklifts are frequently involved in material transport, drying-rack access, and tensioning processes for oversized flags. Operators may need to mount and dismount several times per hour. In this context, the sensor-triggered beeping can lead to both distraction and operator fatigue — a dangerous combination.

An Ohio-based flag manufacturer found that seatbelt sensor overrides improved project fluidity by 22% during print-drying cycles. Their solution? A controlled override paired with visual alert systems and restricted zones marked “LOW-SPEED USE ONLY.”

Pro Conversion Strategy: Combine Sensor Mod with Workflow Planning

Disabling the sensor isn’t a standalone solution — it’s part of a broader conversion optimization tactic. Here’s how to structure it effectively:

Map Your Flow First: Use a process map to isolate high-interruption zones.

Target Forklift Units Strategically: Don’t disable all — just those in controlled, low-risk zones.

Train for Contextual Awareness: Teach operators to self-assess safety vs. efficiency in real time.

Monitor KPIs: Use tools like ForkSight or FleetTrack to measure gains.

Reinstate Sensors Seasonally: Reactivate for peak inventory movement periods when full mobility and speed are restored.

By pairing tactical hardware changes with smarter planning, you’re not just reacting to annoyance — you’re upgrading your operational logic.

By pairing tactical hardware changes with smarter planning, you’re not just reacting to annoyance — you’re upgrading your operational logic. When this strategy is implemented mindfully, it can reshape how smaller arts and decorations enterprises compete in logistical precision.

Reducing Workflow Friction: Human-Centric Forklift Use

In environments focused on high-detail, low-velocity operations — like installing laser-etched glass ornaments or shifting custom-made wooden gifts — user comfort becomes as critical as safety compliance. Operators aren’t just drivers; they’re craftspeople in motion. The disable seatbelt sensor Toyota forklift modification, if applied with boundaries, becomes an enabler of focused craftsmanship.

“We used to spend 15% of our prep time fussing with sensors during warehouse setup for events,” shares Marcus Lee, co-owner of a boutique event branding company. “Since implementing a controlled sensor bypass, we’ve reclaimed that time to double-check design placements and reduce installation errors.”

Human efficiency is rarely about maximum speed — it’s about smooth flow, free from unnecessary friction. That’s the essence of micro-logistics optimization, especially in industries where design detail is king.

Internal Safety Audits: Your Post-Modification Safeguard

One highly effective tactic for ensuring responsible use after you disable seatbelt sensor Toyota forklift components is to implement routine internal audits. This gives you a compliance buffer and strengthens your position in the event of an inspection.

Checklist you can use monthly:

| Are seatbelt-free forklifts used only in low-speed, defined areas? |

| Are operators still wearing seatbelts voluntarily when needed? |

| Has the modified sensor been logged with the forklift’s serial number? |

| Are visual safety reminders posted clearly on the unit? |

| Has a supervisor signed off on the modification in the past 30 days? |

These audits don’t just satisfy paperwork; they build a culture of deliberate action over random workaround.

Future-Proofing: Alternatives to Disabling the Sensor

Before finalizing any hardware bypass, also consider modern tech alternatives now emerging in forklift design:

Smart harness sensors: Aftermarket seatbelt systems that adjust based on movement thresholds.

Proximity-based alerts: Where alarms only trigger near unsafe zones or when forklift speed exceeds set limits.

Operator biometrics: Fingerprint-based systems that override alarms if the registered operator is inside a slow-speed zone.

If your creative business scales or shifts to hybrid warehousing models, these solutions offer flexibility without a full hardware modification. They also help maintain resale value on your Toyota forklift fleet.

Common Mistakes to Avoid When Disabling Seatbelt Sensors

Too often, business owners rush this fix without a clear policy, causing more harm than benefit. Be sure to avoid:

Hardwiring a permanent bypass without a reversal method

Skipping battery disconnection before starting work

Failing to label modified machines

Overgeneralizing: Not all forklifts in your fleet need it

Assuming all operators agree: Some may feel unsafe without the alert

Transparency with your team, technical accountability, and logical use zoning are more powerful than any single hardware tweak.

External Resources to Reference or Link

For added credibility and compliance assurance, consider referencing the following in internal documentation or linking in your internal wiki:

Toyota Material Handling North America: Operator’s Manual Database

OSHA Powered Industrial Truck Standards

NIOSH Recommendations for Forklift Use in Small Business Settings

SAE J2194: Performance Criteria for Seatbelt Systems

Also, link to your local safety consultant or internal training materials so your team knows who to turn to for guidance.

Final Thoughts: Disabling the Seatbelt Sensor Isn’t About Breaking Rules — It’s About Setting Smarter Ones

When you disable seatbelt sensor Toyota forklift systems, you’re not cutting corners — you’re clarifying context. The creative industries that rely on Toyota forklifts aren’t typical. They demand nuance, flexibility, and a deep respect for physical precision. Whether it’s staging a 12-foot seasonal banner or gently sliding handcrafted ceramic boxes onto holiday displays, your operational needs are specific — and deserve equally specific safety-logistical strategies.

Applied with care, tested with metrics, and built into culture — the sensor bypass becomes not a shortcut, but a calibrated shift toward workflow intelligence.