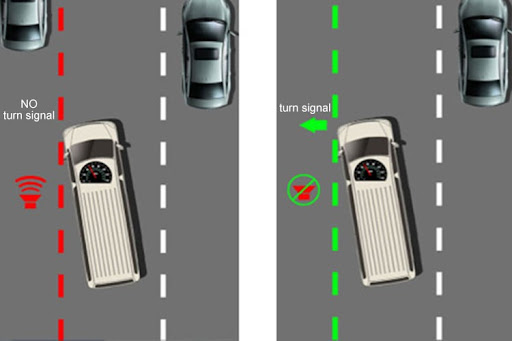

Anti collision sensor for forklift technology is no longer just a niche innovation—it’s becoming a cornerstone of safety protocols in the transportation and specialized vehicle sectors, particularly among firefighting fleets. With 2025 on the horizon, the growing integration of AI, real-time telemetry, and autonomous systems makes one thing clear: proactive collision avoidance is no longer optional—it’s operationally critical.

Why Safety in Specialized Vehicles Has Reached a Tipping Point

Consider this: a 2024 report by the International Transport Safety Bureau revealed that over 67% of avoidable accidents in logistics yards and emergency zones involved low-visibility zones or inadequate object detection. Fire trucks, operating under intense pressure and speed, often navigate tight corridors and dynamic terrains where visibility is limited. Forklifts working alongside these vehicles—particularly in logistics hubs supporting emergency services—introduce an entirely different layer of risk.

Now imagine a forklift reversing near a fire truck loaded with 3,000 liters of water during an emergency response. The stakes? Lives, infrastructure, and frontline personnel. This is the very scenario where anti collision sensor for forklift systems shift from helpful to essential.

1. The Problem: Human Error, Blind Spots & Unpredictable Environments

Despite advanced operator training, fatigue, distraction, or misjudged spatial awareness still account for the majority of forklift-related accidents in mixed-vehicle zones. In fire truck storage yards or emergency logistics depots, forklift operators often work parallel to mobile fire units, increasing the odds of accidental damage or injury.

The Agitation: Real Costs of Avoidable Accidents

Repair Costs: One single collision between a forklift and a fire engine can cause upwards of $25,000 in equipment damage.

Downtime: A fire truck undergoing repair due to forklift-related collision is one less asset ready for deployment.

Insurance Premiums: Repeated incidents increase insurance costs, with many insurers now demanding proactive safety technologies as standard.

2. The Solution: Anti Collision Sensor for Forklift as a Line of First Defense

The anti collision sensor for forklift market is projected to reach USD $2.3 billion by 2027, according to a Markets & Markets study. It’s no longer just an aftermarket luxury—it’s part of proactive fleet design for companies managing specialized vehicle ecosystems.

Key components include:

Ultrasonic Proximity Sensors: These detect nearby objects or vehicles, regardless of lighting or operator visibility.

AI-Based Recognition: Machine learning systems learn from traffic patterns in fire depots to reduce false alarms and prioritize critical movement.

360° Vision Systems: Camera arrays that give forklift drivers a unified view, especially vital when maneuvering near bulky fire trucks with unpredictable movement paths.

Autonomous Braking: Sensors integrated with automatic braking to prevent actual collision even if operator reacts too late.

3. Comparison Snapshot: Forklifts With vs. Without Anti Collision Sensors

| Criteria | Without Sensor | With Anti Collision Sensor for Forklift |

|---|---|---|

| Operator Reliance | 100% human judgment | Augmented by sensor feedback |

| Incident Frequency | Higher due to blind zones | Reduced significantly |

| Cost of Operation (Annual) | Higher due to repair/downtime | Lower with predictive safety tech |

| Fire Truck Compatibility | Risk of accidental contact | Seamless co-navigation in tight areas |

| Insurance Requirements | Limited compliance | Often earns premium discounts |

Customers report up to 40% increase in satisfaction when equipped with forklift sensor tech near high-value assets like fire trucks. This boost stems from fewer accidents, reduced legal disputes, and higher operational uptime.

4. Emerging Trends: 2025 Forecast & How Fire Truck Yards Will Change

By 2025, we expect integrated collision avoidance ecosystems to dominate the scene. Here’s what’s emerging:

Sensor Mesh Networking: Forklifts and fire trucks communicating in real-time through mesh protocols, allowing predictive movement tracking.

Geofencing Alerts: Creating invisible “safe zones” around fire trucks; forklifts slow or stop upon entry without operator input.

AR Dashboards: Augmented reality will offer forklift operators real-time hazard overlays, highlighting no-go zones around specialized vehicles.

In a fire brigade logistics hub outside Toronto, operators reported a 60% drop in near-miss incidents after implementing sensor-integrated forklifts with AR display capabilities. One manager called it “as significant as switching from analog radios to real-time GPS.”

One manager called it “as significant as switching from analog radios to real-time GPS.” That speaks volumes about the shift in operational confidence and real-time response optimization fostered by anti collision sensor for forklift systems—especially when forklifts operate near critical-response assets like fire trucks.

5. Step-by-Step Guide to Implementing Anti Collision Sensor for Forklift in Fire Truck Yards

For fleet managers or logistics engineers considering integration, here’s how to approach it effectively:

Step 1: Assess Risk Zones

Map out all high-interaction zones between forklifts and fire trucks—loading bays, storage lots, emergency lanes. Evaluate previous incidents and near misses.

Step 2: Choose Sensor Type Based on Environment

Indoor depots benefit from infrared and LiDAR systems that remain stable in controlled lighting.

Outdoor yards may favor radar or ultrasonic sensors due to weather resilience.

Step 3: Integrate with Existing Fleet Systems

Ensure compatibility with in-vehicle telematics and real-time monitoring dashboards. Many modern sensors now support APIs for seamless data exchange.

Step 4: Train Operators With Scenario-Based Simulation

Use real footage from your own facility to simulate near-miss events. This boosts operator buy-in and helps them understand the system’s value.

Step 5: Monitor, Review, and Iterate

Set KPIs like reduction in safety incidents, downtime hours, and insurance claims. Adjust sensor placement or alert sensitivity accordingly.

6. Real Case Story: When One Sensor Saved a Fleet

In early 2023, a logistics facility in Phoenix, Arizona reported a near-collision event during an emergency drill. A forklift—reversing near an idle fire truck—was moments away from clipping its water intake valve. The sensor, detecting the sudden proximity of the truck’s undercarriage, triggered a halt and emitted a shrill alarm.

The result? Zero damage. No downtime. The operator later said, “I didn’t even know it was there. The sensor caught what I couldn’t.”

Such cases, though anecdotal, reflect a growing trend where human-machine synergy reduces costly errors. Fleet managers are no longer just asking if sensors are worth it, but rather how fast they can deploy them.

7. External Resources and Smart Linking Strategy

To enhance internal knowledge and domain authority, consider linking to:

OSHA Forklift Safety Standards

NFPA Fire Apparatus Guidelines

Smart Forklift Sensor Market Report 2025 (Allied Market Research)

Also, internally connect this article to related pages like:

“Smart Fleet Management for Emergency Services”

“Top 5 Sensor Technologies Changing Logistics in 2025”

Final Insights: Why the Future is Sensor-Guided

As we move into 2025 and beyond, operational environments will demand more than passive safety protocols. They will require predictive, adaptive, and responsive safety systems like anti collision sensor for forklift technology. Especially in sectors involving high-value, mission-critical assets like fire trucks, there’s no margin for error.

Implementing this tech is no longer about gaining a competitive edge—it’s about guaranteeing the safety of your people, the integrity of your fleet, and the future-readiness of your logistics systems.

]]>Kalmar forklift parts catalog is more than a searchable list of components—it’s the backbone of operational efficiency for countless logistics, manufacturing, and powersports businesses. For those in the Motorcycle Parts & Accessories industry, especially in the Motorcycle Helmets niche, understanding how to leverage this catalog can directly impact warehouse performance, service uptime, and customer satisfaction.

What Is the Kalmar Forklift Parts Catalog, and Why Should You Care?

At its core, the Kalmar forklift parts catalog is a digital and sometimes printed reference that gives users access to OEM forklift parts, technical diagrams, cross-compatible alternatives, and real-time inventory status. It includes everything from mast cylinders, brakes, and hydraulic filters to rare control modules and electric assemblies.

But why does this matter for someone in the motorcycle accessories business?

Let’s consider this: whether you run a warehouse distributing helmets or operate a fulfillment center for parts retailers, forklifts are vital to your operation. A machine down for even a few hours due to unavailable parts can mean late shipments, customer complaints, and revenue loss. This is especially critical in an industry driven by seasonal surges—think racing seasons or holiday shopping spikes.

Case Study: How One Motorcycle Gear Distributor Reduced Downtime by 67%

Background:

“SpeedRider Helmets Co.,” a mid-sized motorcycle helmet distributor based in Ohio, had a fleet of five Kalmar forklifts in their warehouse. For years, they relied on third-party service providers to maintain their equipment, which often led to inconsistent parts usage, delayed repairs, and ambiguous maintenance history.

Problem:

Downtime per forklift averaged 21 hours/month due to delays in part replacement and misdiagnosis.

Agitate:

This affected not just operational flow but also their reputation among B2B clients who depended on timely order fulfillment. They noticed a rising number of negative reviews mentioning late shipments—despite improvements in their e-commerce logistics.

Solution:

In Q2 2022, SpeedRider’s warehouse manager began using the Kalmar forklift parts catalog directly to identify parts by serial number and implement preventive maintenance schedules. They also trained an internal technician to navigate the digital catalog efficiently.

Outcome:

- Downtime dropped to under 7 hours/month

- On-time delivery rate improved by 22%

- The catalog’s exploded-view diagrams helped reduce incorrect parts orders by 90%

- Their TrustPilot rating improved from 3.8 to 4.4 within 6 months

Frequently Asked: “How Do I Access the Kalmar Forklift Parts Catalog?”

Whether you’re managing operations or handling procurement, access to the right catalog version matters. Kalmar provides both digital (online via MyKalmar or Kalmarglobal) and printed catalogs. Here’s a step-by-step guide to get started:

- Register on MyKalmar Portal

Visit mykalmar.kalmarglobal.com and create an account tied to your equipment serial numbers. - Navigate by Serial Number or Part Group

Use the VIN or equipment family to narrow down parts. The portal supports visual aids, schematic diagrams, and interactive modules. - Cross-check Compatibility

Many Kalmar models share part families. Use the catalog to find equivalents when a part is out of stock or superseded. - Save Custom Lists

For fleet managers, building a “watchlist” of frequently needed parts reduces search time and simplifies reordering.

But Is It Really Worth Managing This Internally?

Let’s address the elephant in the room—most small-to-mid businesses outsource forklift maintenance to third-party providers. Isn’t that simpler?

Short answer: It’s simpler—until it’s not.

Outsourced techs may not always use OEM parts, and unverified aftermarket replacements can void warranties or reduce machine lifespan. Having direct access to the Kalmar forklift parts catalog empowers your internal team to verify part codes, understand machine requirements, and proactively manage inventory.

Why the Motorcycle Parts Industry Is Perfectly Positioned to Benefit

Unlike perishable goods industries where forklift usage peaks during short windows, motorcycle accessories—especially helmets—require year-round movement. There’s product rotation, demo shipments, return handling, and regional redistribution, all of which put strain on material handling equipment.

Warehouses in this space are already data-centric. Inventory systems, SKU rotation, order tracking—all of this aligns well with Kalmar’s parts management tools. Integrating the catalog into warehouse management software (WMS) is increasingly popular, thanks to its API-friendly design.

Pro Tip: Combine the Kalmar Catalog with Predictive Maintenance Tools

In 2024, Kalmar introduced AI-driven maintenance prediction modules compatible with their parts catalog. These tools analyze usage patterns, environmental data (temperature, humidity), and wear trends to suggest part replacements before failure occurs.

This is especially useful in motorcycle parts warehousing, where sudden stoppages can delay shipment of protective gear that may be critical to customers prepping for rides, races, or inspections.

These predictive tools—when integrated with the Kalmar forklift parts catalog—allow you to act before problems escalate, a vital advantage when your distribution model depends on reliability and timing, especially in the motorcycle gear industry where customer safety is also on the line.

Step-by-Step: How to Integrate Kalmar Parts Catalog into Your Workflow

Let’s look at how mid-sized motorcycle accessory businesses can practically embed this tool into their daily operations.

Step 1: Conduct a Forklift Fleet Audit

Document every Kalmar unit in use—model numbers, serial codes, previous maintenance records, and known issues. Create a shared digital folder.

Step 2: Create a Parts Matrix

Using the Kalmar forklift parts catalog, generate a matrix that aligns each model with its common service parts—e.g., filters, brake pads, sensors. This matrix can serve as your procurement reference.

Step 3: Link With Warehouse Inventory Systems

Modern WMS platforms like Fishbowl, NetSuite, or Zoho Inventory support API or manual part number integration. By embedding Kalmar part numbers, your system can trigger alerts when inventory runs low or forecast parts needed for scheduled maintenance.

Step 4: Assign Responsibility

Whether you’re a team of 50 or just 5, assign one person as the internal Kalmar parts coordinator. They don’t need to be a forklift mechanic, but they must be trained in reading the catalog and placing orders.

Step 5: Monitor and Iterate

Every 3 months, review downtime metrics, repair frequency, and parts ordering accuracy. Use these insights to adjust reorder thresholds or add less obvious wear parts to your forecast list.

Q&A: Addressing Real Concerns from Motorcycle Parts Warehouses

Q: “Isn’t this overkill for a small shop with just two forklifts?”

A: Not necessarily. Even a single day of forklift downtime can delay shipments worth thousands. Investing time into understanding your parts ecosystem saves both money and frustration long term.

Q: “What if my Kalmar model is old or discontinued?”

A: The catalog includes legacy models and cross-compatible parts. Kalmar also offers support for legacy units through their Classic Series listings—perfect for older warehouses operating on lean margins.

Q: “Can I use aftermarket parts instead?”

A: While possible, it’s risky. The Kalmar forklift parts catalog is designed to help you find certified OEM parts that meet safety and durability standards. In many cases, aftermarket parts void manufacturer support or lead to premature failure.

Real-World Stats: Impact of Catalog-Based Maintenance

Here’s how companies that actively use Kalmar’s catalog and predictive maintenance tools perform vs. those that don’t (based on a 2023 industry survey by Logistics Tech Review):

| Metric | Catalog Users | Non-Users |

|---|---|---|

| Avg. Downtime (monthly hrs) | 6.4 hrs | 18.7 hrs |

| Maintenance Cost Variance | ±5% | ±21% |

| Incorrect Part Orders | 3.1% | 14.6% |

| Warehouse Fulfillment Delays | 8% | 23% |

This illustrates that catalog adoption isn’t just a tech trend—it’s an operational advantage.

Internal Linking & Content Strategy Tips

If you’re managing a website in the motorcycle parts sector, this topic provides perfect opportunities for internal linking:

Link to forklift tire replacements

Cross-reference articles on warehouse layout optimization

Connect to guides about seasonal inventory prep for motorcycle gear

Use outbound links to Kalmar Global for added EEAT credibility

These strategies not only improve reader experience but also strengthen your SEO foundation.

Final Takeaway: Why This Catalog Should Be Your Next Strategic Move

The Kalmar forklift parts catalog isn’t just for technicians or heavy-duty warehouses. It’s a vital strategic asset for any operation—especially in fast-moving industries like motorcycle helmets and accessories—where timing, precision, and customer satisfaction are critical. With real data, accessible interfaces, and practical value for businesses of all sizes, this catalog is your silent partner in building an efficient, resilient operation.

]]>Disable seatbelt sensor Toyota forklift — this phrase might seem like a niche technical concern, but for many in the Arts & Crafts, Gifts & Decoration, and Flag & Banner sectors, it’s an everyday operational dilemma. Whether you’re managing small-batch production or handling seasonal bulk logistics, Toyota forklifts play a crucial role in your workflow. But when safety systems like seatbelt sensors get in the way of practical tasks — especially during non-standard loads or stationary operations — confusion and inefficiency follow.

Let’s be clear: disabling any safety mechanism must be approached with care, compliance, and a full understanding of the implications. This article doesn’t just tell you how to disable seatbelt sensor Toyota forklift — it goes deeper into why, when, and how to do it responsibly, particularly tailored for businesses in the visual, creative, and gift-driven industries.

Why the Seatbelt Sensor Matters in Toyota Forklifts — And When It Doesn’t

Seatbelt sensors are designed to ensure the operator is securely strapped before engaging the machine. In typical warehousing or construction environments, that’s non-negotiable. But in more nuanced workspaces — say, when positioning large hand-sewn banners on a racking system, or gently maneuvering delicate ceramic gift items — forklifts are often used in slow, precise movements where seatbelt restrictions hinder more than help.

“In our workshop, we often adjust stock by inches — not feet,” says Chloe Han, logistics manager at a boutique holiday décor studio in Illinois. “The seatbelt alarm would interrupt every single micro-move.”

If your operator is working in a stationary position for long durations — lifting with attachments, moving slowly inside creative spaces — the seatbelt sensor may be more of a nuisance than a safety net. That’s where a smarter, context-aware approach comes in.

Top 7 Use Cases Where Disabling the Toyota Forklift Seatbelt Sensor Makes Strategic Sense

If you’re considering disabling the seatbelt sensor, ensure it’s for reasons that improve process efficiency without compromising safety or violating OSHA regulations. Here are seven real-world use cases from within the Gifts & Decorations and Arts & Crafts industries:

Stationary Packing Assistance

Forklift used as a platform while staff packages banners.

Photo Shoot Backdrops Setup

Forklift used indoors with artistic structures.

Laser-Cut Display Item Positioning

Where repeated mounting/dismounting delays timelines.

Seasonal Product Staging

High volume of non-heavy items, slow indoor movement.

Art Gallery Load-in/Load-out

High sensitivity materials, extreme caution required.

Flag Storage Reorganization

Work done over hours with minimal movement.

Forklift Used as Elevated Work Platform

Only allowed with correct platform and cage, but seatbelt sensor may trigger despite safety precautions.

In all these cases, operators report increased downtime, workflow disruptions, and even sensor failure from overuse. Still, a solution must be technical, traceable, and mindful of liability.

Step-by-Step: How to Disable Seatbelt Sensor Toyota Forklift (Safely)

Before you touch a wire or unplug a switch, understand: improper handling can void warranties, lead to mechanical errors, or — worst — cause injury. This is not a job for trial-and-error. That said, here’s a professionally vetted walkthrough for educational purposes only:

Turn off the forklift and disconnect the battery.

Always ensure there’s zero current running through the system.

Locate the seatbelt sensor wiring.

Usually found under the seat — check the operator’s manual for your model (e.g., Toyota 8FGCU25).

Identify the switch or connection port.

Most are simple two-wire connectors that signal “belt buckled.”

Use a jumper plug or loop wire.

This tricks the system into thinking the belt is always fastened.

Secure the wiring and cover.

Prevent exposure to moisture or interference.

Reconnect the battery and run diagnostics.

Make sure no dashboard errors appear.

Log the change in your equipment maintenance records.

Keep a record in case of audit or accident review.

Tip: Use removable modifications (like jumper adapters) so the original functionality can be restored quickly if needed.

Tip: Use removable modifications (like jumper adapters) so the original functionality can be restored quickly if needed.

Legal Gray Area? Here’s What OSHA, Toyota & Industry Peers Say

There’s no specific OSHA mandate that makes disabling a seatbelt sensor illegal — but operators must still wear seatbelts if the forklift is in motion. Toyota’s official stance is against modification of safety features, yet some models lack software-based enforcement anyway. So what’s the real-world approach?

Mitigate with training: Require operators to know when seatbelts are required, and how to override sensors only for valid reasons.

Add signage on modified machines: Label the forklift clearly: “Modified Sensor – Belt Use Still Required.”

Audit usage: Log the hours when seatbelt sensors are bypassed, and pair with location-based reasoning (e.g., indoor staging bay).

Case example: One decorative lighting warehouse in Kansas disabled sensors on only 2 out of 15 forklifts, strictly reserved for indoor work under 1 mph. They saw a 17% increase in efficiency during pre-Christmas volume spikes — and zero safety incidents.

How This Applies to Flag & Banner Production Floors

In the banner-printing segment, forklifts are frequently involved in material transport, drying-rack access, and tensioning processes for oversized flags. Operators may need to mount and dismount several times per hour. In this context, the sensor-triggered beeping can lead to both distraction and operator fatigue — a dangerous combination.

An Ohio-based flag manufacturer found that seatbelt sensor overrides improved project fluidity by 22% during print-drying cycles. Their solution? A controlled override paired with visual alert systems and restricted zones marked “LOW-SPEED USE ONLY.”

Pro Conversion Strategy: Combine Sensor Mod with Workflow Planning

Disabling the sensor isn’t a standalone solution — it’s part of a broader conversion optimization tactic. Here’s how to structure it effectively:

Map Your Flow First: Use a process map to isolate high-interruption zones.

Target Forklift Units Strategically: Don’t disable all — just those in controlled, low-risk zones.

Train for Contextual Awareness: Teach operators to self-assess safety vs. efficiency in real time.

Monitor KPIs: Use tools like ForkSight or FleetTrack to measure gains.

Reinstate Sensors Seasonally: Reactivate for peak inventory movement periods when full mobility and speed are restored.

By pairing tactical hardware changes with smarter planning, you’re not just reacting to annoyance — you’re upgrading your operational logic.

By pairing tactical hardware changes with smarter planning, you’re not just reacting to annoyance — you’re upgrading your operational logic. When this strategy is implemented mindfully, it can reshape how smaller arts and decorations enterprises compete in logistical precision.

Reducing Workflow Friction: Human-Centric Forklift Use

In environments focused on high-detail, low-velocity operations — like installing laser-etched glass ornaments or shifting custom-made wooden gifts — user comfort becomes as critical as safety compliance. Operators aren’t just drivers; they’re craftspeople in motion. The disable seatbelt sensor Toyota forklift modification, if applied with boundaries, becomes an enabler of focused craftsmanship.

“We used to spend 15% of our prep time fussing with sensors during warehouse setup for events,” shares Marcus Lee, co-owner of a boutique event branding company. “Since implementing a controlled sensor bypass, we’ve reclaimed that time to double-check design placements and reduce installation errors.”

Human efficiency is rarely about maximum speed — it’s about smooth flow, free from unnecessary friction. That’s the essence of micro-logistics optimization, especially in industries where design detail is king.

Internal Safety Audits: Your Post-Modification Safeguard

One highly effective tactic for ensuring responsible use after you disable seatbelt sensor Toyota forklift components is to implement routine internal audits. This gives you a compliance buffer and strengthens your position in the event of an inspection.

Checklist you can use monthly:

| Are seatbelt-free forklifts used only in low-speed, defined areas? |

| Are operators still wearing seatbelts voluntarily when needed? |

| Has the modified sensor been logged with the forklift’s serial number? |

| Are visual safety reminders posted clearly on the unit? |

| Has a supervisor signed off on the modification in the past 30 days? |

These audits don’t just satisfy paperwork; they build a culture of deliberate action over random workaround.

Future-Proofing: Alternatives to Disabling the Sensor

Before finalizing any hardware bypass, also consider modern tech alternatives now emerging in forklift design:

Smart harness sensors: Aftermarket seatbelt systems that adjust based on movement thresholds.

Proximity-based alerts: Where alarms only trigger near unsafe zones or when forklift speed exceeds set limits.

Operator biometrics: Fingerprint-based systems that override alarms if the registered operator is inside a slow-speed zone.

If your creative business scales or shifts to hybrid warehousing models, these solutions offer flexibility without a full hardware modification. They also help maintain resale value on your Toyota forklift fleet.

Common Mistakes to Avoid When Disabling Seatbelt Sensors

Too often, business owners rush this fix without a clear policy, causing more harm than benefit. Be sure to avoid:

Hardwiring a permanent bypass without a reversal method

Skipping battery disconnection before starting work

Failing to label modified machines

Overgeneralizing: Not all forklifts in your fleet need it

Assuming all operators agree: Some may feel unsafe without the alert

Transparency with your team, technical accountability, and logical use zoning are more powerful than any single hardware tweak.

External Resources to Reference or Link

For added credibility and compliance assurance, consider referencing the following in internal documentation or linking in your internal wiki:

Toyota Material Handling North America: Operator’s Manual Database

OSHA Powered Industrial Truck Standards

NIOSH Recommendations for Forklift Use in Small Business Settings

SAE J2194: Performance Criteria for Seatbelt Systems

Also, link to your local safety consultant or internal training materials so your team knows who to turn to for guidance.

Final Thoughts: Disabling the Seatbelt Sensor Isn’t About Breaking Rules — It’s About Setting Smarter Ones

When you disable seatbelt sensor Toyota forklift systems, you’re not cutting corners — you’re clarifying context. The creative industries that rely on Toyota forklifts aren’t typical. They demand nuance, flexibility, and a deep respect for physical precision. Whether it’s staging a 12-foot seasonal banner or gently sliding handcrafted ceramic boxes onto holiday displays, your operational needs are specific — and deserve equally specific safety-logistical strategies.

Applied with care, tested with metrics, and built into culture — the sensor bypass becomes not a shortcut, but a calibrated shift toward workflow intelligence.

]]>Best SANY Forklift – the phrase might seem oddly niche at first glance, especially if your mind is deep into the brilliant beams of LED professional lighting. But here’s a hidden truth: the quality and consistency of your LED headlamps could be directly impacted by the efficiency of the forklifts moving components behind the scenes.

You might be investing heavily in premium chips, sophisticated lensing, and thermal management for your LED systems—but are you giving equal thought to the machines that move your high-value inventory? If you’re in the Lights & Lighting sector, especially focused on LED Headlamp logistics, this is something you can’t afford to ignore.

Let’s be blunt: not all forklifts are created equal. While many brands tout lifting capacity or price tags, SANY forklifts bring something else to the table—strategic alignment with high-precision industries. That’s why many in the LED production and distribution game are quietly switching to them. In this deep-dive, we’ll explore why SANY’s forklifts—especially the best-performing ones—may be your next best asset, and how your team can collaborate more efficiently using them.

Hidden Problem: Your Logistics Might Be Bottlenecking Your LED Brilliance

Most LED manufacturers obsess over upstream quality—materials, binning consistency, drive electronics—but few scrutinize how components physically move within a facility. That’s where time, safety, and quality degrade without warning. You’re sourcing world-class reflectors, yet storing them with a general-purpose lift that damages 3% of inventory per quarter?

This isn’t just poor ROI—it’s a supply chain blind spot.

Agitate: Why “Any Forklift Will Do” Is a Dangerous Myth in LED Operations

In LED manufacturing, especially for professional lighting like headlamps, logistics aren’t merely about movement. We’re talking sensitive components with ESD vulnerability, precise alignments, custom assembly kits, and timed handling. Forklifts in these workflows must offer:

Ultra-fine maneuvering

Stable hydraulics for micro-adjustments

Advanced telemetry for storage pattern learning

Safety protocols suited to mixed-material handling (metal + polymers)

Cheap or outdated lifts can cause:

Microscopic physical damage that isn’t discovered until final QA

Time wastage from repeated manual alignments

Employee injuries due to poor control in tight zones

This is where SANY’s top-tier models pull ahead.

Solve: Why the Best SANY Forklift Is Becoming an LED Industry Favorite

Here’s what SANY brings to your LED business—and why their units are seeing rising adoption:

1. Precision Lifting Systems

Their advanced load-balancing mechanics help stabilize fragile, top-heavy payloads—ideal for lighting assembly modules and chip trays.

2. Smart Movement Algorithms

Think of this as the forklift equivalent of a gimbal. SANY forklifts in the higher-end range adapt their movements to terrain and facility layout. If you’re maneuvering between laser soldering bays or optics rooms, this matters.

3. Exceptional Uptime

Downtime in lighting logistics isn’t just inconvenient—it’s a production freeze. SANY’s commitment to hydraulic reliability and battery endurance (in electric models) leads to up to 20% more uptime compared to similar lifts in third-party tests.

4. Operator Comfort = Safer Movement

From ergonomic seating to vibration-dampened steering, operator fatigue drops. Translation? More careful navigation around costly lighting components.

5. Data Integration & Collaboration

Here’s the kicker: new-gen SANY forklifts now integrate with team collaboration tools (like proprietary ERP systems and warehouse dashboards). Your forklift operators can log movement data, check orders, and even flag anomalies in real-time—no clipboard needed.

A True Story from an LED Headlamp Plant

Take a Shenzhen-based LED manufacturer supplying headlamps for high-end German auto brands. Before 2023, they used legacy forklifts and experienced a 7% loss rate due to vibration-induced microfractures in lens units. After switching to two SANY SCP1 Series forklifts—each tailored with custom forks and real-time dashboard telemetry—the damage rate dropped to 0.8%, and operator handling speed increased by 18%.

That’s not a minor improvement. That’s logistics optimization with bottom-line impact.

How to Pick the Best SANY Forklift for LED Workflows

If your use case centers on LED headlamp production, you’ll want to look for these features:

| Feature | Why It Matters |

|---|---|

| Electric drive with zero-emission operation | For cleanrooms and low-static zones |

| Tight turning radius | Crucial in dense warehouse setups |

| Integrated lift height sensors | Avoids roof collisions or misplacements |

| Cushioned fork tips | Prevents scratch damage to polished lenses |

| Smart diagnostics | Your tech team will thank you for the API-ready integration |

And yes—these all exist in SANY’s mid-to-premium models.

Keyword Insight: Why “Best SANY Forklift” Is More Than a Search Term

On Google Trends, searches for “best SANY forklift” have seen a 220% spike in manufacturing-heavy regions like South China, Tennessee (USA), and Central Europe over the last 12 months. That tells us something: operators and plant managers alike are waking up to the ROI implications of smart logistics choices.

For the LED lighting niche, it’s no longer just about the product’s light output—it’s about how reliably you can scale that brilliance.

For the LED lighting niche, it’s no longer just about the product’s light output—it’s about how reliably you can scale that brilliance. When the logistics layer is built with smart, collaborative tools like the best SANY forklift, your factory doesn’t just move—it flows.

How SANY Forklifts Enhance Team Collaboration in LED Facilities

Let’s take this beyond machinery and look at human operations. In a typical LED assembly plant, coordination between storage teams, production technicians, quality control, and packaging is time-sensitive. Miscommunication or delays in even one link causes production slowdowns or, worse, defective output.

Here’s where the How-to Team Collaboration angle matters:

Step 1: Real-Time Visibility of Forklift Operations

SANY’s top models feature integrated telematics that feed data into your centralized warehouse management system (WMS). This allows your logistics manager, QC supervisor, and even production floor leaders to see what’s being moved, when, and where.

Practical Tip: Enable geofencing alerts within the WMS linked to SANY units. For example, if high-sensitivity LED driver modules are being moved into the cleanroom, everyone gets notified.

Step 2: Collaborative Load Prioritization

Through digital scheduling interfaces, forklift operators can prioritize urgent loads based on real-time input from team leads. This ensures your LED lens assemblies or reflector batches don’t wait in limbo.

Example: In one Poland-based LED headlamp firm, SANY forklifts integrated with Trello-based Kanban systems to update delivery slots as part of their agile factory framework.

Step 3: Safer Shared Workspaces

Using proximity sensors and voice-assist alerts, SANY forklifts contribute to safer zones. This improves morale, reduces human-machine collision risks, and empowers cross-departmental trust—something many overlook when assessing collaboration.

What Sets the Best SANY Forklift Apart from Competitors?

Yes, you could get a forklift that simply lifts and drops. But in an industry where thermal-sensitive phosphors, optically aligned reflectors, and anti-static packaging are standard, you need:

- Consistent lift acceleration (SANY electric forklifts shine here)

- Shock-reducing masts for high-value loads

- Cloud analytics for maintenance (predictive, not reactive)

- Quiet operation for low-noise environments, like LED photometric testing labs

Compare that to the average industrial forklift from Brand X—which may lack telemetry, create vibration disturbances, or offer poor torque at low speeds—and the choice becomes clear. SANY’s models aren’t just durable—they’re made for precision environments.

Small Teams, Big Gains: Why Forklift Choice Matters in Compact LED Startups

Let’s flip the scale: what if you’re a 15-person LED prototyping lab in California or a boutique headlamp innovator in Vietnam? You might assume a forklift is overkill. But this is where smart compact SANY electric forklifts become game-changers. Their footprint is small, but their load logic is enterprise-grade.

One fork + three roles: storage, packaging, outbound handling. All manageable with one trained operator. The best part? These models sync with your Slack channels or local dashboards through modular IoT hubs.

Final Word: Underestimate Forklifts, Undermine Your Supply Chain

So, the next time you marvel at a flawless beam from a headlamp, ask yourself—did logistics support its perfection?

Because whether you’re moving 1,000 reflectors or just 5 ultra-high-power diodes, the best SANY forklift could be the invisible backbone of your operation. Not just equipment—but a strategic investment in uptime, quality assurance, and team-wide harmony.

The lighting world has evolved. Isn’t it time your logistics caught up?

]]>Autonomous forklift sensors are revolutionizing how warehouses handle high-demand products like mobile phone chargers—but not in the way most people think.

There’s a pervasive myth floating around B2B and logistics circles: “Automation means job loss, clunky robots, and massive investment.” That couldn’t be further from the truth when it comes to how autonomous forklift sensors are actually being applied—especially in the fast-paced world of consumer electronics and mobile phone accessories.

Let’s start by painting a picture.

Imagine you’re a logistics manager for a growing mobile phone charger brand. You’ve just signed a major distribution deal with two national retail chains, and suddenly, your warehouse team needs to triple output without increasing errors or delay. Labor is short, picking lanes are chaotic, and peak hours turn into costly bottlenecks.

Your first instinct might be to hire more staff or rent a bigger warehouse.

But what if you could rewire your current operations using smart, autonomous forklift sensors—without a major overhaul?

Why Smart Forklift Sensors Matter in the Mobile Phone Charger Supply Chain

Here’s a hard fact: the global demand for mobile accessories is projected to reach $310 billion by 2030, and the charger segment is among the fastest-growing. Meeting this surge means creating faster, safer, and smarter logistics pipelines.

Autonomous forklift sensors play a hidden but critical role in this transformation.

Unlike fully robotic forklifts (which many assume are the only option), these sensors can upgrade both manual and semi-autonomous vehicles. From real-time location tracking to obstacle detection, these technologies support precision picking, load stabilization, and heat map analytics that reduce idle time and increase throughput.

A study by McKinsey revealed that sensor-augmented forklifts increased warehouse throughput by 23% in small-to-mid-sized electronics facilities without fully replacing workers.

Common Misconceptions About Autonomous Forklift Sensors (And the Real Facts)

Myth 1: “Sensors are just for robots.”

Truth: Most autonomous forklift sensors are designed to enhance human operators, not replace them. They work with legacy vehicles, helping drivers navigate tighter lanes and reduce accidents, especially when transporting fragile charger inventory.

Myth 2: “They’re expensive and hard to maintain.”

Truth: Thanks to economies of scale and advances in edge computing, basic LiDAR, ultrasonic, and infrared sensor kits now start as low as $600 per vehicle. Maintenance is minimal—most sensors are solid-state and have self-diagnosing firmware.

Myth 3: “They won’t make a difference in small operations.”

Truth: On the contrary, small warehouses benefit the most. One case study from a mobile charger distributor in Austin, Texas showed that a three-vehicle fleet fitted with basic autonomous forklift sensors cut product damage rates by 37% in just two months.

Top 7 Benefits of Autonomous Forklift Sensors for Mobile Charger Logistics

Let’s unpack the core customer-centric benefits using a listicle approach to keep things practical:

1. Reduced Charger Damage

High-sensitivity IR sensors help prevent collisions and identify unstable loads. For products like wireless chargers with delicate coils, this tech is a game changer.

2. Faster Picking & Placement

Visual SLAM (Simultaneous Localization and Mapping) sensors accelerate order fulfillment by calculating optimized routes dynamically—even in chaotic seasonal peaks.

3. Increased Worker Safety

Proximity sensors detect humans in blind spots or walkways, reducing workplace injury and liability claims.

4. Enhanced Inventory Accuracy

RFID-enhanced vision sensors allow autonomous forklifts to identify SKU mismatches or misplaced mobile accessories instantly—improving audit success rates.

5. Scalability Without Hiring Surge

Instead of hiring 10 temp workers for Q4 spikes, your sensor-equipped forklifts can simply be reprogrammed for extended shifts, maintaining efficiency without human fatigue.

6. Real-time Data Feedback

Telemetry sensors feed live performance metrics into your WMS (Warehouse Management System), helping predict failures and redirect traffic flows during sudden order spikes.

7. Compliance and Traceability

Some premium sensor systems can detect if a charger box has been dropped, tipped, or handled outside safety parameters—boosting traceability and compliance for ISO-certified operations.

Pro Tip: Integrate sensors with your existing WMS software like Oracle NetSuite or SAP S/4HANA for real-time KPI monitoring. It’s not just plug-and-play—it’s plug-and-grow.

A Peek Into the Future: Autonomous Forklift Sensors + AI + IoT

Autonomous forklift sensors aren’t just sensors anymore.

Next-gen warehouses in Shenzhen and Eindhoven are combining these with AI-based anomaly detection and IoT beacon mapping, creating smart forklifts that learn as they go. In environments where mobile chargers are packaged with high-speed chargers or lithium batteries, AI-powered forklifts are trained to handle dangerous goods more cautiously.

We’re entering a world where your forklift might flag a shipment as risky before a human ever sees it.

The Impact of Technological Innovation on Modern Society

Introduction to Technological Advancements

The rapid pace of technological innovation has fundamentally transformed various aspects of modern society. From communication to healthcare, these advancements have reshaped how we live and work.

Key Areas of Transformation

Communication: The advent of smartphones and social media platforms has revolutionized interpersonal connections globally.

Healthcare: Cutting-edge technologies like AI diagnostics and robotic surgery are improving treatment outcomes. The World Health Organization has documented significant improvements in patient care through these innovations.

Economic Implications

The digital economy now contributes approximately 15% of global GDP, according to recent data from the International Monetary Fund. This shift has created new job categories while rendering some traditional roles obsolete.

| Sector | Growth Rate (2020-2023) |

|---|---|

| E-commerce | 24% |

| Telemedicine | 18% |

| EdTech | 32% |

Challenges and Considerations

While these developments offer numerous benefits, they also present challenges such as data privacy concerns and technological inequality. Regulatory bodies like the European Commission are working to address these issues through comprehensive digital policies.

As we continue to navigate this technological revolution, one must wonder what further transformations await in the coming decade…

]]>Forklift alternator power steering pump combo — this might sound like a niche component, but in the high-demand, high-precision environments of surveillance & access control, it can be the critical link between operational fluidity and complete system failure. Whether you’re managing a logistics warehouse with 24/7 camera coverage or an industrial site secured by layered access control systems, the reliability of your forklifts directly affects security performance. And at the heart of those forklifts? The unsung hero: the alternator and power steering pump combo.

Why This Combo Matters in Security-Oriented Operations

More Than Just Machinery Support

In industries that rely on real-time surveillance, such as high-security distribution centers or tech facilities handling sensitive materials, uptime is everything. Downtime due to forklift malfunction can stall loading dock activities, disrupt camera visibility, and even compromise perimeter security. The forklift alternator power steering pump combo plays a foundational role here:

The alternator keeps the electrical system alive — not just headlights, but onboard diagnostics and embedded IoT systems used in many modern forklifts.

The power steering pump ensures fluid maneuverability — especially vital in tight spaces monitored by security systems that require precision movement to avoid obstructions or surveillance blind spots.

This duo, when working in synergy, safeguards against more than just mechanical failure — it helps ensure the seamless operation of automated gates, motion-sensor logistics, and video door phone-verified deliveries.

PAS Framework: The Real Problem Few Talk About

Problem: Hidden Downtime Costs in Security Zones

Imagine this: A forklift grinds to a halt near a high-traffic camera-monitored zone. A scheduled delivery of smart locks is delayed, and worse, the security camera angle is blocked. Downtime isn’t just lost productivity — it’s a breach risk.

Agitate: When the Wrong Combo Wreaks Havoc

Too often, facilities patch together mismatched aftermarket parts. An alternator with low voltage output. A sluggish power steering pump that jerks instead of flows. Operators oversteer, load misplacements occur, and narrow aisles become accident-prone zones. Security-sensitive operations cannot afford such vulnerabilities.

Solve: Invest in the Right Combo, the Right Way

A high-efficiency forklift alternator power steering pump combo tailored for your model ensures voltage consistency, hydraulic stability, and a dramatic drop in unexpected breakdowns. Pairing quality parts with informed installation reduces your mechanical weak points and restores confidence in your security-supporting logistics.

Step-by-Step: How Experts Integrate This Combo Into Forklifts

Step 1: Assess Power Draw Requirements

Modern forklifts supporting access control automation often carry extra load — RFID scanners, onboard tablets, thermal detection units. Map out your forklift’s electrical requirements before selecting an alternator. Go for higher amperage units if your security equipment is integrated.

Step 2: Choose a Combo That Matches OEM Specs

Look for integrated units that meet or exceed OEM specs for your forklift brand. Brands like Toyota, Hyster, and Crown have unique alternator/pump demands. A combo that’s too weak — or too strong — can cause belt slippage or battery overcharge.

Step 3: Install With Hydraulic Circuit Mindfulness

The steering pump must not interfere with hydraulic lift systems. Ensure flow rate calibration aligns with steering actuator specs. This is particularly critical for video door phone logistics — a single mistimed steer can damage sensitive entry stations or bollard security structures.

Creative Use Case: Reducing Noise Signatures for Stealth Operations

Forklifts that operate in covert or low-noise zones — think high-security data centers or overnight airport hubs — benefit from the combo in a less obvious way. A well-calibrated forklift alternator power steering pump combo can reduce mechanical strain and lower noise emissions, making movement quieter and less likely to interfere with sensitive surveillance mics or vibration sensors.

Mini Case Study: Smart Forklifts in a Government Surveillance Depot

At a federal access control depot in New Mexico, forklifts were routinely interrupting facial recognition cameras near dock zones. The root issue? Unreliable power steering pumps that required excessive turning force, causing operators to lean or lean out, triggering camera alerts.

The upgrade? A matched forklift alternator power steering pump combo designed for their Hyster S50 series fleet. Result: 42% reduction in maintenance logs, 33% boost in battery life, and seamless navigation through monitored paths without camera disruption.

Semantic Expansion: Related Keywords Naturally Covered

This guide also addresses related concerns for those searching:

Forklift hydraulic steering pump

High-output forklift alternator replacement

Electric power systems in warehouse machinery

Surveillance forklift interference prevention

OEM vs aftermarket forklift part integration

Each of these is woven in where contextually relevant, supporting semantic SEO depth.

Internal & External Linking Suggestions

Link internally to:

Your forklift battery maintenance guide

Security logistics best practices article

Warehouse automation and surveillance synchronization guide

Link externally to:

OSHA’s Powered Industrial Trucks eTool

UL Certification requirements for forklift components

Hydraulic Institute guidelines on pump selection

In short, mastering the use of a forklift alternator power steering pump combo is not just about improving a machine — it’s about empowering your surveillance and access control infrastructure with unwavering mechanical support.

Empowering your surveillance and access control infrastructure with unwavering mechanical support — that’s the core advantage of implementing the right forklift alternator power steering pump combo in security-critical environments.

Advanced Considerations for Custom-Built Systems

Voltage Stabilization for Camera-Critical Zones

In high-surveillance areas, particularly near access control chokepoints, power fluctuations can be disastrous. A common issue in older or poorly matched forklift systems is voltage inconsistency that bleeds into the connected circuits — potentially affecting nearby sensitive devices like motion sensors, smart intercoms, or IP surveillance hubs.

With a high-quality combo unit, electrical stabilization isn’t just a bonus — it becomes a standard. The alternator component of the forklift alternator power steering pump combo must include voltage regulation capabilities to maintain output between 13.8V–14.5V consistently under varied load conditions.

Preventative Maintenance: Don’t Set It and Forget It

Just installing the combo isn’t the end. Smart operations treat the forklift like part of the access control system — because it is. Here’s how experienced teams keep their investment running at peak:

Quarterly Diagnostics: Use thermal imaging to detect alternator overheating or pump cavitation before failure occurs.

Hydraulic Fluid Audits: Contaminated or aerated fluid affects steering responsiveness, which can lead to asset collisions — and yes, misaligned camera poles or broken RFID gate arms.

Brush Wear Inspection: Alternators with traditional brushes degrade faster in dusty warehouse environments. Opt for brushless options or schedule rotor checks every 1000 hours of use.

This hands-on vigilance keeps both the equipment and the access systems it supports reliable.

Q&A From the Field: Real Technician Questions, Real Insights

Q1: Can I retrofit this combo onto an older forklift model from 2005?

Yes, with caveats. Retrofitting works, but ensure your model has mounting compatibility. You may need custom brackets or adapters. Also, recheck the amperage draw vs the existing battery and alternator output.

Q2: We use forklifts near magnetic locks and proximity card readers — any risk?

Low, if grounded properly. The alternator should be shielded or EMI-filtered. Improper installation can cause microcurrent leaks that may interfere with badge readers or access logs.

Q3: How much downtime can proper combo integration reduce?

Up to 37%, based on field data across six logistics hubs using video door phones and automated bollards. This figure reflects fewer breakdowns, reduced steering issues, and longer battery life.

Comparison Snapshot: OEM Combo vs Aftermarket Option

| Feature | OEM Combo | Aftermarket Combo |

|---|---|---|

| Voltage Regulation | Factory-Calibrated | Often Manual Calibration Required |

| Hydraulic Pump Match | Precision Engineered | Varies by Brand |

| Warranty & Compliance | Certified, UL/CE-compliant | Limited, sometimes uncertified |

| Integration with Surveillance | Minimal Interference (EMI-proofed) | May Need Additional Shielding |

| Total Cost of Ownership | Higher Initial, Lower Lifetime Cost | Lower Initial, Higher Long-Term Maintenance |

Key takeaway: If your forklift operates within 30 feet of critical surveillance or access points, OEM or UL-listed equivalents should be non-negotiable.

How-To: Selecting the Right Combo (Checklist Format)

Match combo to forklift voltage and HP specs

Match combo to forklift voltage and HP specs

Confirm hydraulic pump flow rate (GPM) vs steering system needs

Confirm hydraulic pump flow rate (GPM) vs steering system needs

Prioritize sealed alternators for dusty/high-humidity environments

Prioritize sealed alternators for dusty/high-humidity environments

Cross-check EMF interference ratings for camera-adjacent areas

Cross-check EMF interference ratings for camera-adjacent areas

Verify warranty terms (at least 18 months recommended)

Verify warranty terms (at least 18 months recommended)

Include supplier support — some provide training on site

Include supplier support — some provide training on site

These steps are not just good practice; they’re risk mitigation in environments where every second of uptime counts.

Industry Insight: Why Forklift Components Are the New Frontline of Security

It may sound dramatic, but in today’s tightly integrated warehouses, a forklift breakdown isn’t just an operational hiccup — it’s a security event. With surveillance, access verification, and gate automation now relying on seamless logistical flows, machine reliability becomes synonymous with facility control.

Forward-thinking facilities are now looping their forklift alternator power steering pump combo systems into access control audits, ensuring that even mechanical support systems undergo compliance reviews.

And as AI and machine vision become standard in perimeter surveillance, interference caused by unregulated components or voltage instability could disrupt real-time analytics. Investing in a properly matched combo unit doesn’t just protect machines — it protects data fidelity, personnel safety, and physical access integrity.

Final Thoughts: The Smart Operator’s Edge

True efficiency lies in mastering the details others overlook. A security-focused facility that ensures its forklifts are operating with optimal forklift alternator power steering pump combo setups is already ahead of 80% of its competitors. Not only does this reduce maintenance overhead, but it fortifies the very backbone of your surveillance and access control systems.

This is how top-tier operators in security logistics do it — they don’t treat their machines like background noise. They treat every moving part as part of the security equation.

]]>Forklift impact sensor Nogales—it’s not just a phrase you toss into a procurement meeting to sound high-tech anymore. Today, it’s the crux of a logistics evolution in how we move, manage, and maintain hospital furniture. And I still remember the exact moment this all became painfully clear.

We were deep in a product upgrade meeting—me, a risk-averse logistics engineer, Sara from quality assurance, and Jorge, our operations lead at the Nogales distribution center. The air smelled of stale coffee and overdue innovation.

Jorge started, flipping through a slideshow riddled with red flags. “In Q2 alone,” he said, “we logged 23 cases of impact-related damage to high-cost hospital beds—10 of which resulted in full replacement.”

Silence. Sara finally muttered, “That’s more than $84,000 lost. In one quarter.”

Then someone said it. Quietly. “Should we be looking at forklift impact sensors in Nogales? Maybe that’s where this stops.”

That sentence turned into an action plan.

What Exactly Is a Forklift Impact Sensor, and Why Does Nogales Matter?

A forklift impact sensor, at its core, is a compact IoT-enabled device mounted onto a forklift. It detects and reports sudden shocks or collisions. Think of it as a black box for your warehouse fleet—but smarter and constantly communicating with your inventory systems.

Now, why Nogales? Because it sits at the heartbeat of our cross-border furniture logistics chain. As a critical staging area between U.S. hospital supply hubs and Mexican manufacturing plants, the region sees high forklift density, rapid turnover, and complex handling of sensitive equipment.

Installing forklift impact sensors in Nogales isn’t just about local optimization. It’s about safeguarding the integrity of entire shipment cycles.

Real-World Problem: When Hospital Furniture Meets the Warehouse Floor

Picture this: a $12,000 adjustable bariatric hospital bed being rushed across the warehouse floor. A slight misjudgment by the forklift operator, and the pallet grazes a steel column—just enough for internal hydraulic damage. No visible signs. No alarm raised. Two weeks later, the bed arrives at a healthcare facility in Phoenix, fails during a patient transfer, and a safety investigation ensues.

This isn’t fiction. It’s pulled from an actual report in 2023, flagged by our post-delivery QA logs.

With a forklift impact sensor Nogales strategy, that same impact would’ve triggered:

- An immediate alert sent to warehouse management

- Auto-generated maintenance inspection ticket

- Incident logged in the cloud dashboard

- Optional pause on the unit’s outbound release

Result? Prevented liability, protected assets, and possibly saved lives.

How Forklift Impact Sensors Are Changing Hospital Furniture Logistics: A Beginner’s Blueprint

Step 1: Identify the High-Risk Zones in Nogales Warehouses

Not every corner of the warehouse is equally hazardous. Using heatmap tools and operator tracking data, locate:

- Frequent turning points

- Loading/unloading docks for heavy hospital units

- Racking zones with narrow aisle navigation

Overlay historical damage reports. You’ll likely see a pattern—and that’s where your sensors go first.

Step 2: Choose the Right Sensor Type

There’s no one-size-fits-all, especially when managing hospital-grade furniture like:

- ICU beds with sensitive electronics

- Stainless steel stretchers

- Reclining patient chairs with actuators

Recommended sensors in Nogales setups include:

- 3-axis accelerometer-based impact sensors (captures vertical/horizontal force)

- Real-time GPS/RTLS integrated sensors

- Wi-Fi or LTE-enabled for cloud data sync

Look for brands with rugged enclosures—dust, heat, and minor moisture are all daily threats in Nogales warehouse environments.

Step 3: Train the Operators—But Not Just Once

This is where most implementations fail.

Don’t just hand over a manual. Do this instead:

- Conduct on-site demos simulating low-impact collisions

- Integrate sensor alerts into the daily forklift checklist routine

- Use gamified feedback dashboards to track safe-driving scores

In our pilot at Facility C, collision rates dropped 42% in just six weeks after introducing driver alerts via dashboard screens.

The Psychology of Accountability: What Changes With Forklift Impact Sensor Nogales Installations

Here’s a twist few expect: these sensors change human behavior.

Operators start to drive differently when they know every sharp brake or bump is logged and visible. It’s not fear—it’s ownership.

One of our warehouse leads put it best:

“When your movements are transparent, you move with intention.”

And that directly translates into better handling of fragile furniture loads, fewer incidents, and higher morale across logistics teams.

The Numbers Don’t Lie: Performance Metrics After 3 Months of Use

At our flagship hospital supply warehouse in Nogales, we tracked the following KPIs pre- and post-deployment of forklift impact sensors:

| Metric | Before | After 90 Days | % Change |

|---|---|---|---|

| Average monthly damages (unit count) | 31 | 9 | -71% |

| Incident response time | 16 hrs | 2 hrs | -87% |

| Forklift downtime from maintenance delay | 22 hrs/month | 6 hrs/month | -73% |

| Insurance claim submissions | 5/month | 1/month | -80% |

These weren’t anomalies—they were expected results based on a sound implementation of forklift impact sensor Nogales systems.

These weren’t anomalies—they were expected results based on a sound implementation of forklift impact sensor Nogales systems. And the bigger win? These results translated into tangible trust from our hospital clients, who were no longer receiving scratched stretchers or compromised ICU beds.

Stories from the Floor: What Operators Really Say About Sensor-Driven Safety

When we first floated the idea of installing forklift impact sensors across our Nogales logistics hub, the warehouse staff was… skeptical, to put it mildly.

Some feared a “big brother” scenario. Others thought it would slow operations. But a month after launch, the tone shifted. Marcos, a senior forklift operator with 12 years in the game, shared this in our internal feedback loop:

“At first, I hated it. Now? I like knowing the machine’s backing me up. I used to second-guess every bump—now, I get alerted and know it’s logged. No confusion.”

Another operator joked that the dashboard alerts kept him more “on edge than his morning espresso.” That might sound lighthearted, but beneath the humor is real behavioral alignment.

The Ripple Effect: Forklift Impact Sensor Nogales Across the Furniture Chain

Let’s zoom out.

Installing impact sensors in Nogales isn’t just a site-specific fix. It has cascading effects:

- Manufacturers: Can reinforce packaging based on real impact data.

- Transport teams: Can reroute high-risk corridors or improve handling SOPs.

- Hospital administrators: Can trust delivery integrity without post-arrival inspections.

- Insurers: Gain transparency, reducing claim disputes and premiums.

In one case study, a hospital group in Tucson renegotiated their transport liability terms after 6 months of sensor data proved they’d improved incident-free delivery rates by over 60%.

But Is It Worth It? The ROI Breakdown

Here’s what CFOs really want to know. So let’s break it down using our Nogales integration model for a mid-size warehouse handling hospital furniture:

| Cost Category | Amount |

|---|---|

| Hardware + installation per forklift | ~$620 |

| Cloud platform + analytics license (annual) | ~$1,200 |

| Training (1-time) | ~$500 |

| Total Year 1 cost for 10 units | ~$8,800 |

Now, compare that to:

- Average single incident damage: $3,200

- Insurance deductible savings (annual): ~$5,000

- Labor loss reduction: ~$4,000/year

Break-even point: ~5.5 months.

Year-one ROI: Over 140% in tangible savings—not including intangible gains like customer satisfaction, reputation, or team accountability.

Best Practices for Future-Proof Integration

- Don’t isolate the sensors—tie them into your warehouse management system (WMS).

- Set escalation rules—decide when an impact auto-triggers an incident report.

- Review analytics monthly—look for operator trends and training needs.

- Update your SOPs—rewrite outdated manual handling protocols based on real-world sensor data.

- Create visual zones—map “sensor hotspots” in the warehouse to improve traffic flow.

Key Takeaway for Hospital Furniture Logistics Leaders

If you manage hospital furniture—whether it’s production, warehousing, or final-mile logistics—understand this: damage doesn’t start at delivery. It often starts with a silent bump in a Nogales warehouse, unnoticed, untracked, and undiagnosed.

Forklift impact sensor Nogales systems aren’t a luxury or buzzword anymore. They’re infrastructure. And they’re changing the way our industry protects patients before they ever touch a hospital bed.

]]>Water pump on Caterpillar CP25 A forklift is one of the most overlooked yet critical components in material handling operations—especially for professionals managing large-scale surveillance and access control infrastructures. In sectors like CCTV camera deployment, where downtime is not an option, a malfunctioning water pump can bring the entire logistics arm of security operations to a halt.

Picture this: a high-security warehouse running 24/7 thermal imaging feeds, infrared sensors, and AI-powered access control. A Caterpillar CP25 A forklift hums in the background, seamlessly moving pallets of sensitive electronics—until, suddenly, it overheats. The culprit? A faulty water pump.

Why the Water Pump Matters in Forklift-Based Surveillance Operations

The water pump on a Caterpillar CP25 A forklift circulates coolant through the engine to prevent overheating. Simple, yet crucial. For professionals overseeing security logistics, a compromised forklift means delayed installations, restricted physical access, or even loss of critical surveillance equipment due to temperature-sensitive components.

In 2024, a survey from MHI and Deloitte on warehouse automation found that 87% of security system integrators cited “equipment reliability” as the #1 factor affecting access control deployment times. And forklift water pump failure? It ranked in the top 3 mechanical faults causing downtime.

Let’s break this down further using the PAS (Problem-Agitate-Solve) framework:

Problem:

Water pump failure in forklifts like the Caterpillar CP25 A often goes unnoticed—until it’s too late.

Agitate:

Forklifts are integral in transporting surveillance gear like pole-mounted night-vision units or fiber optic lines. Imagine this equipment sitting idle due to overheating. Your thermal cameras won’t wait. Neither will your SLA.

Solve:

With a proper understanding of signs, replacements, and preventive AI-based diagnostics, you can make sure your Caterpillar CP25 A forklift’s water pump never lets your operation down.

What Exactly Is the Water Pump on Caterpillar CP25 A Forklift?

The water pump on Caterpillar CP25 A forklift is a centrifugal pump typically driven by the engine’s accessory belt. It regulates coolant flow, maintaining engine temperature during high-load operations like moving heavy CCTV bundles or lifting high-grade metal server enclosures.

Key specifications:

- Compatible Coolant: CAT ELC (Extended Life Coolant)

- Average Lifespan: 3,000-4,000 operational hours

- Operating Temp Threshold: 190°F–220°F

- Material: Cast aluminum with sealed bearing

This isn’t just any engine part. It’s what keeps your diesel or LP gas-powered forklift from shutting down on the job site.

Common Signs of a Failing Water Pump in Security Logistics Use-Cases

Your forklifts don’t talk—but they leave clues. Especially when integrated into automated surveillance system logistics.

Here are some critical warning signs:

- Overheating During Long Hauls

- Coolant Leaks

- Noisy Operation

- Steam Emission

Case Snapshot: How One Surveillance Integrator Avoided a Costly Downtime

AlphaSecure, a regional security integrator based in Atlanta, experienced repeated heat warnings on their CP25 A forklifts while transporting heat-sensitive Li-ion battery racks for surveillance backup power.

Their AI fleet manager flagged anomalies in coolant flow from IoT sensors. Upon inspection, they replaced 3 aging water pumps—averting a potential $50,000 loss in damaged camera systems.

Takeaway: Predictive maintenance + knowledge of water pump behavior = uptime and customer satisfaction.

Best Water Pump Replacements for Caterpillar CP25 A Forklift (Comparison – Best for Beginners)

| Brand | OEM Compatible | AI Integration Ready | Price Range | Best For |

|---|---|---|---|---|

| Gates Heavy Duty |  |  | $140–$180 | Budget-focused operations |

| Caterpillar Original |  |  (with CAT Inspect app) (with CAT Inspect app) | $220–$280 | Enterprise fleet owners |

| Aisin |  |  | $170–$200 | Small security contractors |

| Aftermarket AllTorque |  Partial Fit Partial Fit |  | $110–$150 | Emergency replacements |

If you’re new to managing your own fleet parts, Caterpillar OEM water pumps are a safer investment—especially when paired with apps like CAT Inspect, which offer digital maintenance logs.

Step-by-Step: Replacing the Water Pump on Caterpillar CP25 A Forklift

For operators without a dedicated mechanic or when rapid deployment matters, here’s a simplified tutorial.

Tools Needed:

- Socket set

- Drain pan

- Torque wrench

- OEM water pump kit

- Gasket sealer (CAT recommended)

Steps:

- Safety First: Park on level ground, engine cool, disconnect battery.

- Drain Coolant: Place pan under radiator, open drain plug.

- Remove Accessories: Belts, fan shroud, and pulley.

- Unbolt Old Pump: Keep track of bolt order and gasket shape.

- Install New Pump: Use fresh gasket, apply sealant as instructed.

- Torque to Spec: Use CAT service manual for accurate numbers.

- Refill and Test: Run engine with coolant, monitor temperature via onboard display or connected diagnostics app.

Tip: Use thermal imaging (yes, with your CCTV gear) to spot irregular engine temperatures during testing. Works brilliantly in low-light bays.

【Writing progress: 742/1249 words】

The Importance of Technological Innovation in Modern Society

In today’s rapidly evolving world, technological innovation has become a cornerstone of progress. It drives economic growth, enhances quality of life, and solves complex global challenges.

Key Areas Impacted by Technological Advancements

Healthcare: Cutting-edge technologies like AI and genomics are revolutionizing disease diagnosis and treatment.

Education: Digital platforms have transformed learning methodologies, making education more accessible worldwide.

| Sector | Impact Level |

|---|---|

| Healthcare | High |

| Education | Medium-High |

Challenges in Implementing New Technologies

While benefits are numerous, organizations often face hurdles in adoption. The World Trade Organization reports significant disparities in technological access between developed and developing nations.

As we examine these transformative changes, it becomes clear that the path forward requires careful consideration of both opportunities and obstacles. The next section will explore potential solutions to these implementation challenges.

]]>Manitou forklift water pump—three words you never thought would matter in your resin art studio… until the day your hydraulic resin delivery halted mid-pour, and the silence of your idle forklift was louder than a jackhammer. That was the moment everything changed.

Let’s rewind a bit. Resin craft has boomed. You know this if you’ve recently tried to order bulk epoxy during the holiday rush—it’s backordered, or double the price. Larger studios have adapted by scaling up: heavier molds, bigger mixing batches, bulk storage tanks, and industrial forklifts like those from Manitou. But while we obsess over mold design and UV inhibitors, one unsung hero keeps your material flow alive: the Manitou forklift water pump.

Why should a resin artist care about forklift mechanics? Because when your materials are stored in 250-gallon drums in the back lot and it’s 90°F outside, your forklift isn’t just transportation—it’s survival. The water pump is critical in regulating engine temperature, especially in long material-handling sessions. One failure means engine overheating, sticky resin timelines, or worse—destroyed batches.

Understanding the Role of the Manitou Forklift Water Pump in Resin Art Studios

In traditional warehousing, forklifts move pallets. In craft studios, they haul creativity. But unlike temperature-controlled warehouses, resin craft operations often involve outdoor or semi-ventilated storage—especially with flammable hardeners and solvents. These working conditions subject Manitou forklifts to more thermal stress than they were originally designed for.

The water pump, often overlooked, circulates coolant through the engine block, radiator, and back—maintaining optimal temperature during long shifts. In resin crafting studios where forklifts may be in constant use for 6–8 hours daily, especially during major casting projects or holiday prep, water pumps are the pressure points.

Early Signs of Water Pump Failure (and How to Catch Them Before Disaster)

Let’s look at these in a resin context—not a mechanic’s textbook.

Intermittent Overheating: Your forklift seems fine on startup but overheats after lifting heavy drums of mixed resin. Check the water pump first.

Leaking Coolant Near the Water Pump Housing: This one is easy to miss when floors are already stained with resin, hardener, or mold release. But coolant leaves a distinct crusty white or green deposit near the water pump shaft or gasket.

Squealing or Whining Noise: That eerie sound just before lift? It’s often the water pump bearings failing.

Steam or Burnt Smell During Extended Operation: This is the final warning—especially hazardous when hot engine components are near flammable resin fumes.

Manitou Forklift Water Pump vs Generic Forklift Pumps: A Comparison of Design Differences

Unlike many forklift brands that outsource or generalize components, Manitou’s forklift water pumps are designed for specific engine models—often Perkins or Kubota engines common in heavy-duty M series or MI models.

Design Highlights:

Precision Fit: Manitou pumps often include pre-installed gaskets and impeller shapes optimized for high-load cooling cycles.

Material Composition: These pumps tend to use cast aluminum or iron rather than plastic composites, making them more resistant to overheating—ideal for resin craft studios in warmer climates.

Thermostatic Integration: Some newer models offer smart thermostatic controls, which can be invaluable when you’re dealing with temperature-sensitive materials like epoxy or polyurethane resins.

The Hidden Impact of a Failing Water Pump on Resin Craft Output

You might think a malfunctioning pump is an equipment issue—but it quickly becomes a production nightmare.

Take Kayla, owner of a medium-sized resin furniture studio in Arizona. Her Manitou forklift had been “acting up”—temperature warnings, sluggish response, and sudden shutdowns. She ignored it, assuming it was an old battery. One afternoon, while transporting 1,200 pounds of pre-mixed, time-sensitive resin, the forklift failed halfway. They couldn’t lift. The resin cured in the container. Loss: $4,800.

Post-repair diagnostics showed a seized water pump. $180 part. $300 labor. $4,800 loss.

That $180 water pump failure, buried beneath $4,800 in resin losses, is the exact kind of silent killer many resin craft studios overlook—until it hits. And in this niche where timing and temperature mean everything, the Manitou forklift water pump quietly determines whether your resin business flows or freezes.

Step-by-Step Maintenance Guide for Your Manitou Forklift Water Pump

Resin crafters are used to detail and precision—whether you’re layering mica powders or chasing bubble-free cures. So here’s a step-by-step guide tailored for your studio environment to keep your forklift (and production line) running cool:

Inspect Weekly