Contents

- 1

- 1.1 Why Safety in Specialized Vehicles Has Reached a Tipping Point

- 1.2 1. The Problem: Human Error, Blind Spots & Unpredictable Environments

- 1.3 The Agitation: Real Costs of Avoidable Accidents

- 1.4 2. The Solution: Anti Collision Sensor for Forklift as a Line of First Defense

- 1.5 3. Comparison Snapshot: Forklifts With vs. Without Anti Collision Sensors

- 1.6 4. Emerging Trends: 2025 Forecast & How Fire Truck Yards Will Change

- 1.7 5. Step-by-Step Guide to Implementing Anti Collision Sensor for Forklift in Fire Truck Yards

- 1.8 6. Real Case Story: When One Sensor Saved a Fleet

- 1.9 7. External Resources and Smart Linking Strategy

- 1.10 Final Insights: Why the Future is Sensor-Guided

Anti collision sensor for forklift technology is no longer just a niche innovation—it’s becoming a cornerstone of safety protocols in the transportation and specialized vehicle sectors, particularly among firefighting fleets. With 2025 on the horizon, the growing integration of AI, real-time telemetry, and autonomous systems makes one thing clear: proactive collision avoidance is no longer optional—it’s operationally critical.

Why Safety in Specialized Vehicles Has Reached a Tipping Point

Consider this: a 2024 report by the International Transport Safety Bureau revealed that over 67% of avoidable accidents in logistics yards and emergency zones involved low-visibility zones or inadequate object detection. Fire trucks, operating under intense pressure and speed, often navigate tight corridors and dynamic terrains where visibility is limited. Forklifts working alongside these vehicles—particularly in logistics hubs supporting emergency services—introduce an entirely different layer of risk.

Now imagine a forklift reversing near a fire truck loaded with 3,000 liters of water during an emergency response. The stakes? Lives, infrastructure, and frontline personnel. This is the very scenario where anti collision sensor for forklift systems shift from helpful to essential.

1. The Problem: Human Error, Blind Spots & Unpredictable Environments

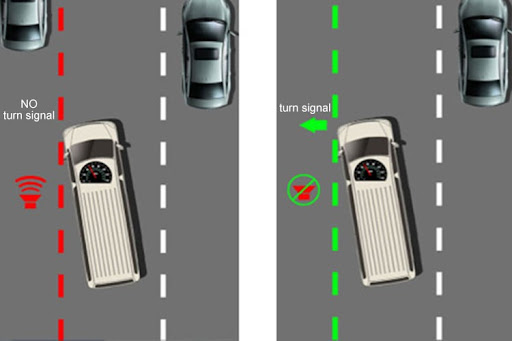

Despite advanced operator training, fatigue, distraction, or misjudged spatial awareness still account for the majority of forklift-related accidents in mixed-vehicle zones. In fire truck storage yards or emergency logistics depots, forklift operators often work parallel to mobile fire units, increasing the odds of accidental damage or injury.

The Agitation: Real Costs of Avoidable Accidents

Repair Costs: One single collision between a forklift and a fire engine can cause upwards of $25,000 in equipment damage.

Downtime: A fire truck undergoing repair due to forklift-related collision is one less asset ready for deployment.

Insurance Premiums: Repeated incidents increase insurance costs, with many insurers now demanding proactive safety technologies as standard.

2. The Solution: Anti Collision Sensor for Forklift as a Line of First Defense

The anti collision sensor for forklift market is projected to reach USD $2.3 billion by 2027, according to a Markets & Markets study. It’s no longer just an aftermarket luxury—it’s part of proactive fleet design for companies managing specialized vehicle ecosystems.

Key components include:

Ultrasonic Proximity Sensors: These detect nearby objects or vehicles, regardless of lighting or operator visibility.

AI-Based Recognition: Machine learning systems learn from traffic patterns in fire depots to reduce false alarms and prioritize critical movement.

360° Vision Systems: Camera arrays that give forklift drivers a unified view, especially vital when maneuvering near bulky fire trucks with unpredictable movement paths.

Autonomous Braking: Sensors integrated with automatic braking to prevent actual collision even if operator reacts too late.

3. Comparison Snapshot: Forklifts With vs. Without Anti Collision Sensors

| Criteria | Without Sensor | With Anti Collision Sensor for Forklift |

|---|---|---|

| Operator Reliance | 100% human judgment | Augmented by sensor feedback |

| Incident Frequency | Higher due to blind zones | Reduced significantly |

| Cost of Operation (Annual) | Higher due to repair/downtime | Lower with predictive safety tech |

| Fire Truck Compatibility | Risk of accidental contact | Seamless co-navigation in tight areas |

| Insurance Requirements | Limited compliance | Often earns premium discounts |

Customers report up to 40% increase in satisfaction when equipped with forklift sensor tech near high-value assets like fire trucks. This boost stems from fewer accidents, reduced legal disputes, and higher operational uptime.

4. Emerging Trends: 2025 Forecast & How Fire Truck Yards Will Change

By 2025, we expect integrated collision avoidance ecosystems to dominate the scene. Here’s what’s emerging:

Sensor Mesh Networking: Forklifts and fire trucks communicating in real-time through mesh protocols, allowing predictive movement tracking.

Geofencing Alerts: Creating invisible “safe zones” around fire trucks; forklifts slow or stop upon entry without operator input.

AR Dashboards: Augmented reality will offer forklift operators real-time hazard overlays, highlighting no-go zones around specialized vehicles.

In a fire brigade logistics hub outside Toronto, operators reported a 60% drop in near-miss incidents after implementing sensor-integrated forklifts with AR display capabilities. One manager called it “as significant as switching from analog radios to real-time GPS.”

One manager called it “as significant as switching from analog radios to real-time GPS.” That speaks volumes about the shift in operational confidence and real-time response optimization fostered by anti collision sensor for forklift systems—especially when forklifts operate near critical-response assets like fire trucks.

5. Step-by-Step Guide to Implementing Anti Collision Sensor for Forklift in Fire Truck Yards

For fleet managers or logistics engineers considering integration, here’s how to approach it effectively:

Step 1: Assess Risk Zones

Map out all high-interaction zones between forklifts and fire trucks—loading bays, storage lots, emergency lanes. Evaluate previous incidents and near misses.

Step 2: Choose Sensor Type Based on Environment

Indoor depots benefit from infrared and LiDAR systems that remain stable in controlled lighting.

Outdoor yards may favor radar or ultrasonic sensors due to weather resilience.

Step 3: Integrate with Existing Fleet Systems

Ensure compatibility with in-vehicle telematics and real-time monitoring dashboards. Many modern sensors now support APIs for seamless data exchange.

Step 4: Train Operators With Scenario-Based Simulation

Use real footage from your own facility to simulate near-miss events. This boosts operator buy-in and helps them understand the system’s value.

Step 5: Monitor, Review, and Iterate

Set KPIs like reduction in safety incidents, downtime hours, and insurance claims. Adjust sensor placement or alert sensitivity accordingly.

6. Real Case Story: When One Sensor Saved a Fleet

In early 2023, a logistics facility in Phoenix, Arizona reported a near-collision event during an emergency drill. A forklift—reversing near an idle fire truck—was moments away from clipping its water intake valve. The sensor, detecting the sudden proximity of the truck’s undercarriage, triggered a halt and emitted a shrill alarm.

The result? Zero damage. No downtime. The operator later said, “I didn’t even know it was there. The sensor caught what I couldn’t.”

Such cases, though anecdotal, reflect a growing trend where human-machine synergy reduces costly errors. Fleet managers are no longer just asking if sensors are worth it, but rather how fast they can deploy them.

7. External Resources and Smart Linking Strategy

To enhance internal knowledge and domain authority, consider linking to:

OSHA Forklift Safety Standards

NFPA Fire Apparatus Guidelines

Smart Forklift Sensor Market Report 2025 (Allied Market Research)

Also, internally connect this article to related pages like:

“Smart Fleet Management for Emergency Services”

“Top 5 Sensor Technologies Changing Logistics in 2025”

Final Insights: Why the Future is Sensor-Guided

As we move into 2025 and beyond, operational environments will demand more than passive safety protocols. They will require predictive, adaptive, and responsive safety systems like anti collision sensor for forklift technology. Especially in sectors involving high-value, mission-critical assets like fire trucks, there’s no margin for error.

Implementing this tech is no longer about gaining a competitive edge—it’s about guaranteeing the safety of your people, the integrity of your fleet, and the future-readiness of your logistics systems.