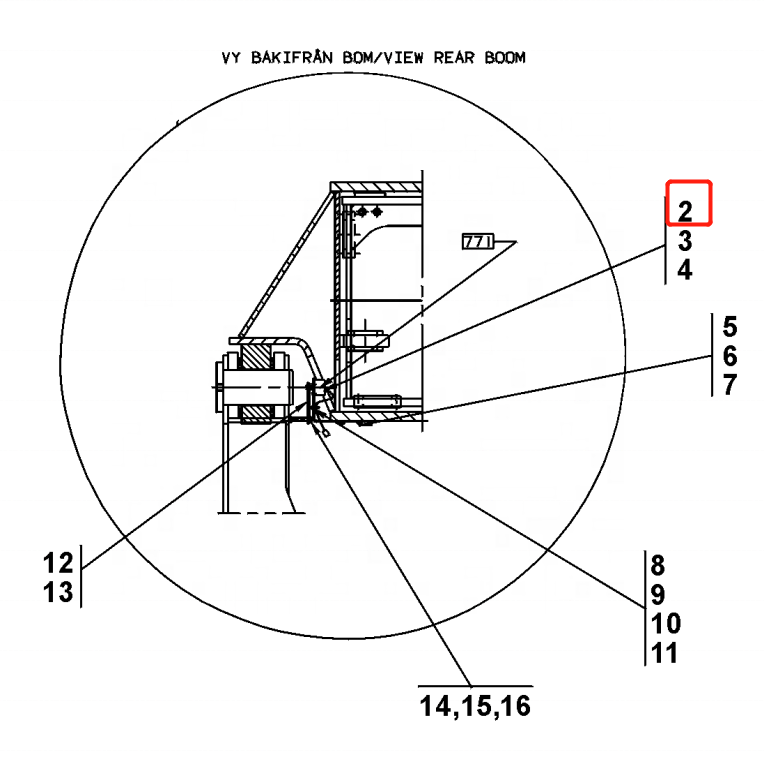

A40607.0100 for KALMAR DRF 400-450 DRF Boom Length Sensor PW613-35d/GS20 Container Reach Stacker Crane Spare Parts

The Boom Length Sensor is a vital component for ensuring the safe, efficient, and accurate operation of construction machinery

A40607.0100 for KALMAR DRF 400-450 DRF Boom Length Sensor PW613-35d/GS20 Container Reach Stacker Crane Spare Parts - Advanced Analysis

The Boom Length Sensor is an essential component used in construction machinery, particularly in cranes, excavators, and material handling equipment. It is designed to accurately measure the length of the boom, ensuring that operators can monitor and control the extension and retraction of the boom with precision. The sensor plays a critical role in ensuring the safe and efficient operation of the machinery by providing real-time feedback on the boom’s position, which is crucial for load handling and preventing potential accidents or mechanical failures.

The Boom Length Sensor works by detecting the displacement or position of the boom and converting this information into an electrical signal that can be processed by the machine’s control system. This data is then used to adjust the machine’s operations accordingly. Whether extending the boom to lift heavy loads or retracting it for storage or transport, the sensor ensures that the correct boom length is maintained, allowing for safer and more accurate movements.

In crane operations, for example, knowing the exact boom length is critical when lifting and positioning heavy loads. The Boom Length Sensor provides operators with immediate and accurate data, helping to prevent overextension or miscalculation of the machine’s reach. This not only improves safety but also enhances the efficiency of the operation, allowing the crane to perform tasks faster and with greater control.

The Boom Length Sensor also plays an important role in protecting the equipment. Overextending the boom can put undue stress on the machine’s hydraulic system and other structural components, leading to potential damage or wear. By providing constant feedback on the boom’s position, the sensor helps ensure that the boom operates within safe limits, thus extending the lifespan of the equipment and minimizing the risk of costly repairs or downtime.

The design of the Boom Length Sensor is engineered to withstand the demanding conditions of construction sites and industrial environments. These sensors are built to operate effectively in harsh conditions, such as extreme temperatures, high vibrations, dust, and exposure to moisture. The materials used in the construction of the sensor are highly durable, ensuring reliable operation over extended periods, even under heavy use and challenging environmental conditions.

Another key feature of the Boom Length Sensor is its integration with the machine’s overall control system. The sensor communicates with the machine’s onboard electronics, providing real-time data that allows for precise control of the boom. In modern machines, this sensor works in conjunction with other sensors, such as load moment sensors or angle sensors, to provide a comprehensive understanding of the machine’s status and performance. This integrated system ensures that the machine’s operations are optimized, improving both safety and efficiency.

In addition to providing crucial data to the operator, the Boom Length Sensor is also used in automated systems to increase productivity and reduce human error. In many machines, the sensor is integrated into the automation system, allowing for automatic boom adjustments based on the load or task at hand. This helps streamline operations, reduce operator fatigue, and increase the overall effectiveness of the equipment.

Regular maintenance and calibration of the Boom Length Sensor are essential to ensuring its continued accuracy and performance. Over time, environmental factors or mechanical wear can cause the sensor to drift, leading to inaccurate measurements. Routine checks and recalibration help maintain the sensor’s precision, ensuring that the machine continues to operate safely and efficiently. Additionally, any signs of damage or malfunction should be addressed immediately to prevent any adverse effects on the machine’s operation.

In conclusion, the Boom Length Sensor is a vital component for ensuring the safe, efficient, and accurate operation of construction machinery, cranes, and material handling equipment. By providing real-time data on the boom’s position, it helps operators manage the machine’s reach, ensuring that it operates within safe limits and that the load is handled efficiently. Its durability, precision, and ability to integrate with the machine’s control system make the Boom Length Sensor indispensable in modern industrial applications. Regular maintenance and timely replacement of the sensor are essential for maintaining the equipment’s longevity and performance.

For more information on the regulations and standards related to Boom Length Sensors and other industrial components, you can visit the official website of the Occupational Safety and Health Administration (OSHA) at https://www.osha.gov/.

1. Durable boom length sensor for construction machinery

2. High-performance boom length sensor for crane operations

3. Accurate boom length sensor for safe load handling

4. Reliable boom length sensor for automated machine control

5. Long-lasting boom length sensor for industrial equipment

Bulk Source A40607.0100 for KALMAR DRF 400-450 DRF Boom Length Sensor PW613-35d/GS20 Container Reach Stacker Crane Spare Parts

Direct Factory Pricing | OEM/ODM Customization | GRS Certified Materials