SQM11 Cummins Injectors 4903472, 924015.1008 for KALMAR DRT450 Stacker Reach Stacker Parts and Accessories

SQM11 Cummins Injectors 4903472, 924015.1008 for KALMAR DRT450 Stacker Reach Stacker Parts and Accessories - Advanced Analysis

Cummins Injectors 4903472 / 924015.1008 for KALMAR DRT450 – Engine Precision You Can Trust

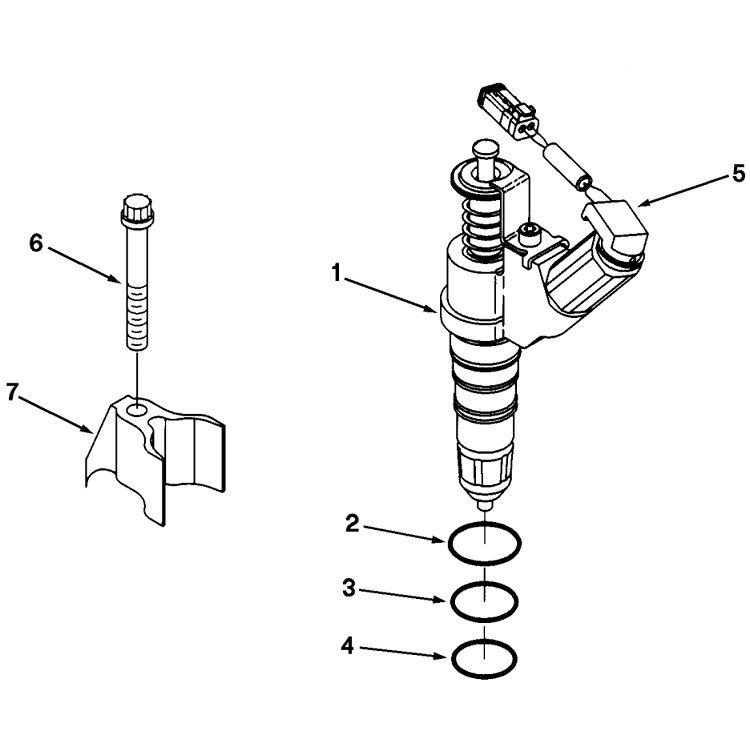

For industrial equipment like the KALMAR DRT450 Reach Stacker, engine performance isn’t a luxury—it’s a necessity. Our high-precision Cummins Injectors, part numbers 4903472 and 924015.1008, are designed specifically for the Cummins QSM11 diesel engine. These fuel injectors play a vital role in delivering precise fuel quantity and spray patterns to optimize combustion, efficiency, and durability in port and logistics environments.

Why Choose Genuine Cummins Injectors for QSM11?

Fuel injection systems are central to diesel engine operation. A small deviation in spray angle or pressure can lead to increased fuel consumption, higher emissions, and reduced engine life. Our Cummins Injectors are OEM-quality replacements, compatible with the factory-installed systems in KALMAR heavy-duty equipment.

Product Details

- Product Name: Fuel Injector Assembly

- Part Numbers: 4903472 / 924015.1008

- Engine Compatibility: Cummins QSM11

- Equipment: Kalmar DRT450 Reach Stacker

- Fuel Type: Diesel

How These Cummins Injectors Improve Engine Performance

By delivering high-pressure, precisely-timed diesel fuel into the combustion chamber, these Cummins Injectors help:

- Enhance fuel efficiency and power output

- Minimize engine knock and vibration

- Reduce harmful emissions and black smoke

- Ensure smoother engine startup and stable idle

Field-Proven and Industry-Approved

Our Cummins Injectors have been tested under real-world conditions in container yards, ports, and freight terminals. They are the industry’s preferred choice for consistent fuel delivery in demanding environments. These injectors align with the U.S. Department of Energy’s standards for fuel efficiency and emissions reduction technologies.

Common Use Cases in Kalmar DRT450 Stackers

The KALMAR DRT450 is a powerful reach stacker used for heavy container handling. Its QSM11 engine depends on stable, reliable injection to operate at peak performance. These Cummins Injectors ensure:

- Reduced operational downtime

- Longer engine service intervals

- Fewer fuel system failures

- Better adaptability to variable fuel quality

Customer Pain Points Solved

Our injectors are engineered to eliminate several common issues faced by industrial equipment operators:

- Inconsistent Fuel Delivery: Advanced nozzles and solenoid actuation ensure precision timing.

- High Fuel Costs: Improved atomization reduces fuel waste and increases mileage per gallon.

- Excessive Emissions: Cleaner combustion helps meet strict environmental standards.

- Component Wear: Uniform combustion reduces stress on pistons and valves.

Installation & Compatibility

These injectors are direct replacements for OEM 4903472 / 924015.1008 and require no special modifications. Installation should be performed by certified technicians to ensure correct torque and calibration settings.

Certifications and Quality Standards

All components meet or exceed ISO and OEM specifications. As diesel emission standards continue to evolve, these Cummins Injectors remain compliant with emission protocols under the U.S. Clean Diesel Initiative, ensuring longevity and environmental compliance.

Maintenance Tips

- Use only high-quality diesel fuel to prevent clogging.

- Replace injectors every 150,000–200,000 km depending on usage environment.

- Use compatible fuel filters to prevent premature wear.

- Run diagnostic tests regularly to check injection

Bulk Source SQM11 Cummins Injectors 4903472, 924015.1008 for KALMAR DRT450 Stacker Reach Stacker Parts and Accessories

Direct Factory Pricing | OEM/ODM Customization | GRS Certified Materials