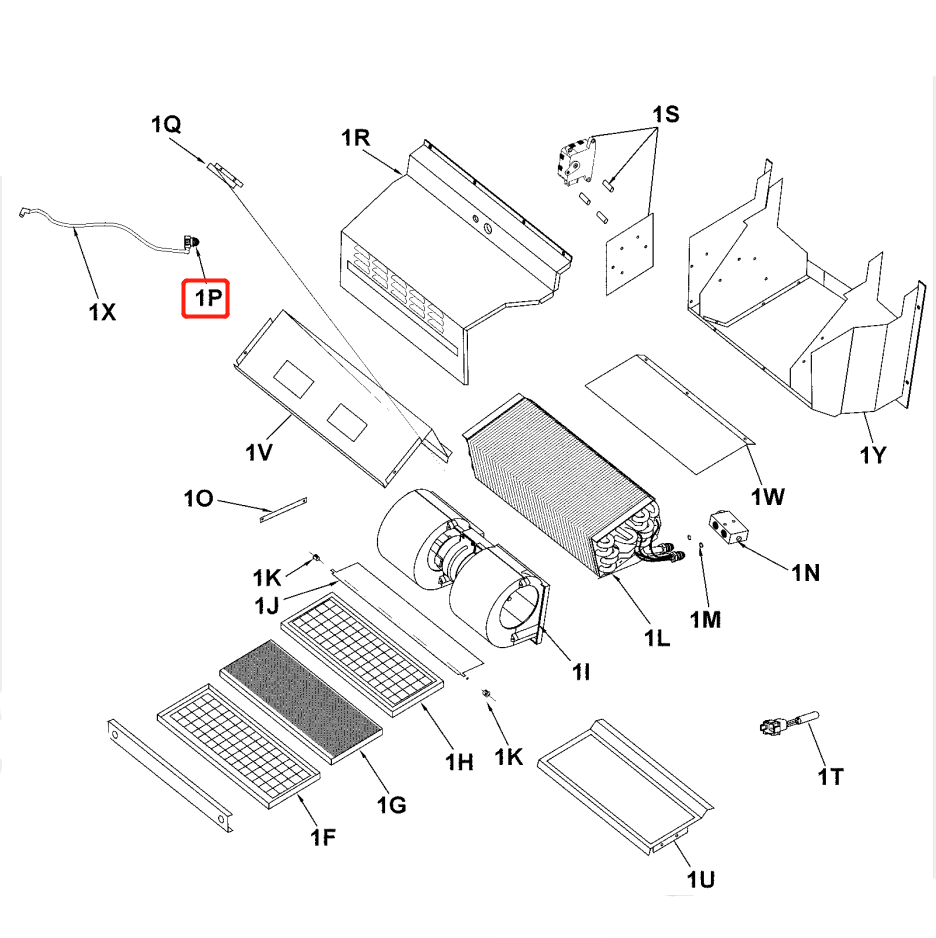

920169.013 for KALMAR DCF 80-100 DCT80-90 Air Conditioning Indoor Sensor Container Reach Stacker Crane Spare Parts

the Air Conditioning Sensor is an indispensable part of the HVAC system in KALMAR’s industrial equipment and heavy-duty machinery.

920169.013 for KALMAR DCF 80-100 DCT80-90 Air Conditioning Indoor Sensor Container Reach Stacker Crane Spare Parts - Advanced Analysis

The Air Conditioning Sensor is a critical component in the air conditioning system of KALMAR’s heavy-duty machinery, including container handlers, reach stackers, and forklifts. This sensor is responsible for monitoring and regulating the air conditioning system’s temperature, humidity, and pressure levels, ensuring that the system operates efficiently and maintains a comfortable environment for operators in harsh industrial environments. Whether used in high-performance vehicles or industrial equipment, the Air Conditioning Sensor plays a key role in optimizing air conditioning performance, enhancing energy efficiency, and protecting sensitive components from potential damage caused by irregular temperature fluctuations.

The Air Conditioning Sensor provides real-time data to the vehicle’s electronic control unit (ECU) or HVAC system, allowing it to adjust the cooling or heating output as needed. By measuring parameters such as temperature and pressure, the sensor ensures that the air conditioning system operates within optimal ranges, preventing overheating or undercooling that could lead to system malfunctions or inefficiencies. This proactive monitoring not only helps maintain operator comfort but also reduces the risk of costly repairs and downtime due to HVAC system failures.

In industrial environments, where equipment often operates in extreme conditions such as high heat, humidity, or dust, the Air Conditioning Sensor ensures that the air conditioning system adapts to these challenges. By keeping the internal cabin temperature at a consistent and comfortable level, the sensor helps reduce operator fatigue and improve performance, which is crucial for maintaining productivity in demanding environments such as container terminals, warehouses, and construction sites.

The Air Conditioning Sensor is designed to be highly durable, capable of withstanding exposure to harsh environmental conditions, including high temperatures, vibrations, and moisture. Given the intense demands placed on industrial machinery, it is essential for this sensor to function reliably over long periods, providing continuous and accurate readings. Constructed from rugged materials, it ensures that the sensor can perform effectively without failure, even in high-stress conditions. This durability minimizes maintenance requirements and contributes to the overall longevity of the air conditioning system, enhancing the performance and reliability of KALMAR equipment.

This sensor also plays an important role in improving the overall energy efficiency of the HVAC system. By ensuring that the system operates within the correct parameters, the Air Conditioning Sensor helps reduce unnecessary energy consumption, which can have a significant impact on operational costs. Whether in vehicles or heavy-duty machinery, the efficient operation of the air conditioning system, supported by accurate sensor data, helps minimize fuel consumption and reduces the carbon footprint of the equipment, aligning with sustainable business practices.

Additionally, the Air Conditioning Sensor can contribute to the safety of the machinery. In extreme operating conditions, if the sensor detects that the system is not functioning within optimal parameters (such as dangerously low or high temperatures), it triggers the appropriate response from the system, ensuring that the air conditioning operates at the correct levels and prevents further damage to the vehicle’s cabin environment or mechanical components. This safety feature helps protect both the operator and the equipment, ensuring smooth and uninterrupted operation.

Regular maintenance and inspection of the Air Conditioning Sensor are essential to ensure that it continues to function at peak performance. Over time, the sensor may wear out due to exposure to contaminants, wear, or aging components. Signs of a malfunctioning sensor may include inconsistent cabin temperature, reduced cooling or heating efficiency, or irregular pressure levels in the HVAC system. Regular inspection, cleaning, and timely replacement of the sensor can help maintain the system’s efficiency and prevent costly repairs or disruptions in service.

In conclusion, the Air Conditioning Sensor is an indispensable part of the HVAC system in KALMAR’s industrial equipment and heavy-duty machinery. By ensuring that the air conditioning system operates efficiently and reliably, the sensor enhances both operator comfort and machine performance. Its durability, precision, and contribution to energy efficiency make it a vital component in maintaining the overall reliability and safety of KALMAR equipment. Routine maintenance and replacement of the sensor ensure optimal system performance, protecting both the machinery and the operators.

For more information regarding the regulations and standards related to air conditioning systems in vehicles and machinery, including the Air Conditioning Sensor, you can visit the official website of the National Highway Traffic Safety Administration (NHTSA) at https://www.nhtsa.gov/.

1. Durable air conditioning sensor for industrial machinery

2. High-performance air conditioning sensor for heavy-duty equipment

3. Reliable air conditioning sensor for maintaining optimal cabin temperature

4. Efficient air conditioning sensor for energy-saving operation

5. Long-lasting air conditioning sensor for improved operator comfort

Bulk Source 920169.013 for KALMAR DCF 80-100 DCT80-90 Air Conditioning Indoor Sensor Container Reach Stacker Crane Spare Parts

Direct Factory Pricing | OEM/ODM Customization | GRS Certified Materials