920030.004 for KALMAR DCE 80-100/45E 731 Injector Copper Sleeve 276130 Container Reach Stacker Crane Parts Accessories

The Injector Copper Sleeve is also designed for easy installation and replacement, which is crucial for minimizing downtime in commercial and industrial operations.

920030.004 for KALMAR DCE 80-100/45E 731 Injector Copper Sleeve 276130 Container Reach Stacker Crane Parts Accessories - Advanced Analysis

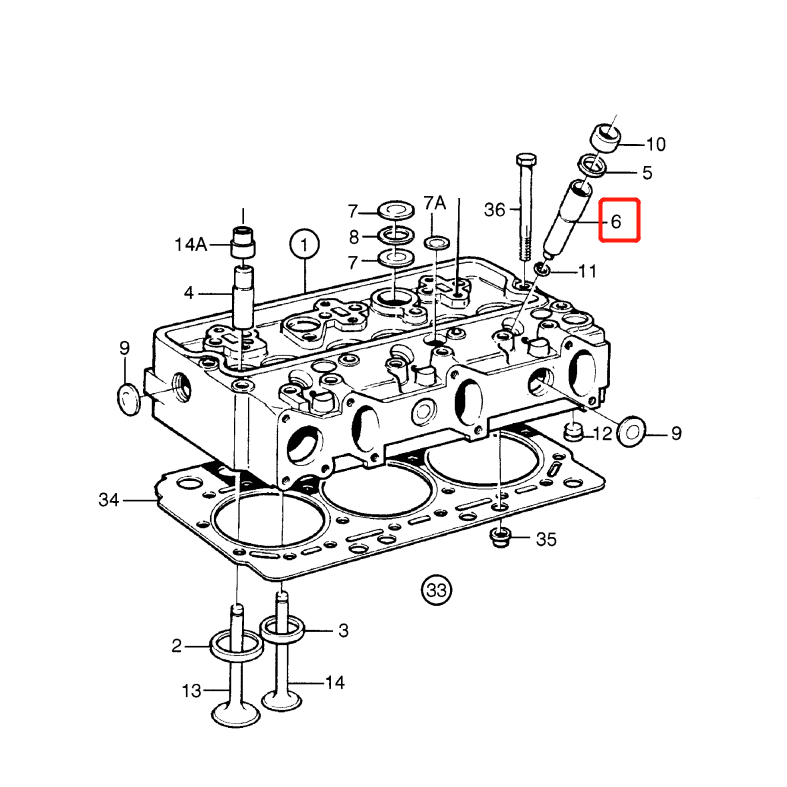

The Injector Copper Sleeve is an essential component in fuel injection systems, designed to provide a secure, durable interface between the fuel injector and the engine block. Typically made of high-quality copper, this sleeve plays a crucial role in ensuring a proper seal for the injector, preventing fuel leakage, and protecting the injector from heat damage and corrosion. By acting as a buffer between the injector and the engine, the Injector Copper Sleeve helps maintain optimal injector function, ensuring efficient fuel delivery and engine performance.

The Injector Copper Sleeve works by providing a stable and secure housing for the fuel injector nozzle, which is responsible for delivering fuel into the combustion chamber. The sleeve ensures that the injector remains firmly seated in place, maintaining a proper seal and preventing any fuel from leaking around the injector. This is especially important in high-pressure environments, such as those found in modern diesel and gasoline engines, where precise fuel injection is critical for maintaining engine efficiency, reducing emissions, and improving fuel economy.

One of the main advantages of the Injector Copper Sleeve is its ability to withstand the extreme conditions within the engine. Copper, known for its excellent thermal conductivity and resistance to corrosion, ensures that the sleeve remains durable even under high temperatures and constant exposure to engine fluids. The material’s natural ability to dissipate heat helps to protect the injector from overheating, which can lead to injector failure, poor fuel atomization, and a drop in engine performance.

In addition to providing a physical barrier, the Injector Copper Sleeve also contributes to the overall efficiency of the fuel injection system. A properly fitted sleeve ensures that the injector operates within optimal parameters, delivering fuel precisely where it is needed for combustion. By preventing fuel leaks and protecting the injector from damage, the sleeve helps to maintain consistent fuel pressure and flow, ensuring that the engine runs smoothly and efficiently.

The Injector Copper Sleeve is particularly important in vehicles and machinery with high-performance or high-compression engines, such as commercial trucks, construction equipment, and agricultural machinery. In these applications, where engine performance and reliability are paramount, the sleeve ensures that the injectors function properly, reducing the risk of injector-related failures and extending the life of the engine. Furthermore, the sleeve’s role in maintaining fuel efficiency makes it essential in industries where operational costs are closely tied to fuel consumption.

As part of routine maintenance, it is crucial to inspect the Injector Copper Sleeve for signs of wear, corrosion, or damage. Over time, exposure to heat, pressure, and engine fluids can cause the sleeve to degrade, potentially leading to fuel leaks, poor injector performance, or engine misfires. In these cases, replacing the copper sleeve promptly is essential to avoid further engine damage and ensure that the fuel system continues to function effectively.

The Injector Copper Sleeve is also designed for easy installation and replacement, which is crucial for minimizing downtime in commercial and industrial operations. Technicians can quickly replace a worn or damaged sleeve during routine engine maintenance, ensuring that the injector remains properly seated and the fuel system continues to operate smoothly. In some cases, the sleeve may need to be replaced alongside other injector components to maintain optimal performance and ensure that the fuel system operates as efficiently as possible.

In conclusion, the Injector Copper Sleeve is a small but essential component that plays a critical role in maintaining the efficiency, durability, and performance of the fuel injection system. By ensuring a secure, leak-free connection between the injector and the engine block, the sleeve helps prevent fuel leaks, protect the injector from heat damage, and maintain optimal fuel delivery. Whether in high-performance vehicles, commercial trucks, or heavy machinery, the Injector Copper Sleeve contributes to the overall reliability and efficiency of the engine. Regular inspection and timely replacement of the sleeve are key to ensuring that the injector system continues to operate at its best, keeping engines running smoothly and efficiently.

For further information on regulations and standards related to components like the Injector Copper Sleeve, you can visit the official website of the National Highway Traffic Safety Administration (NHTSA) at https://www.nhtsa.gov/.

1. Durable injector copper sleeve for fuel system performance

2. High-quality injector copper sleeve for engine protection

3. Efficient injector copper sleeve for preventing fuel leakage

4. Long-lasting injector copper sleeve for improved injector lifespan

5. Reliable injector copper sleeve for maintaining engine efficiency

Bulk Source 920030.004 for KALMAR DCE 80-100/45E 731 Injector Copper Sleeve 276130 Container Reach Stacker Crane Parts Accessories

Direct Factory Pricing | OEM/ODM Customization | GRS Certified Materials