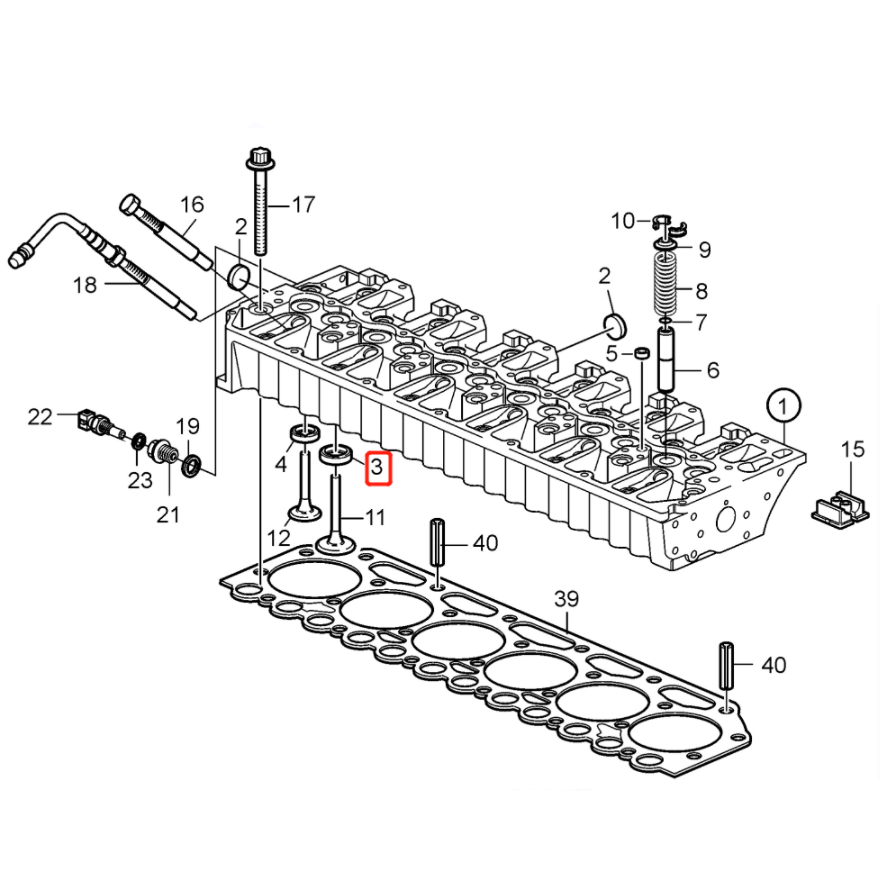

720 Intake Valve Seat Ring 20459962, 923976.0378, 0425 2442 For KALMAR DCE 80-100/45E

The Intake Valve Seat Ring is an essential component in ensuring the proper functioning of an engine’s intake system.

720 Intake Valve Seat Ring 20459962, 923976.0378, 0425 2442 For KALMAR DCE 80-100/45E - Advanced Analysis

The Intake Valve Seat Ring is a critical component in internal combustion engines, playing an essential role in sealing the contact area between the intake valve and the cylinder head. This part ensures that the engine’s intake valve operates efficiently, providing a tight seal that allows for optimal compression and fuel mixture flow into the combustion chamber. By preventing the leakage of air-fuel mixture during the intake stroke, the Intake Valve Seat Ring contributes to the engine’s overall performance, power output, fuel efficiency, and emission control.

The primary function of the Intake Valve Seat Ring is to provide a durable, high-performance seating surface for the intake valve. The intake valve opens to allow the air-fuel mixture to enter the combustion chamber and then closes to seal the chamber during compression and combustion. The Intake Valve Seat Ring creates a tight seal when the valve is closed, ensuring that no gases escape and that the engine maintains the correct air-fuel ratio for efficient combustion. The ring is designed to withstand the heat, pressure, and mechanical stress placed on it during engine operation, ensuring that the intake valve operates effectively over time.

In automotive applications, the Intake Valve Seat Ring is typically made from high-quality materials such as hardened steel, stainless steel, or heat-resistant alloys. These materials are selected for their ability to endure high temperatures and pressures, as well as their resistance to wear and corrosion. The intake valve and valve seat ring are subjected to extreme conditions within the engine, where temperatures can reach several hundred degrees Celsius and pressures can be immense. As such, the Intake Valve Seat Ring must maintain its integrity under these demanding conditions to ensure the long-term reliability and efficiency of the engine.

The Intake Valve Seat Ring plays a significant role in enhancing the performance of the engine by ensuring proper sealing. A poor seal between the intake valve and the seat can lead to loss of compression, reduced engine efficiency, and increased emissions. In contrast, a well-functioning intake valve seat ring helps optimize engine power by ensuring that the intake valve operates smoothly, allowing for precise control over the intake of the air-fuel mixture. This, in turn, improves the combustion process, enhancing overall engine performance and efficiency.

In addition to improving engine performance, the Intake Valve Seat Ring also plays a role in fuel economy. When the intake valve and seat ring are functioning properly, the engine operates more efficiently, requiring less fuel to produce the same amount of power. A tight seal ensures that the fuel mixture entering the combustion chamber is precisely metered, preventing wasteful overfuelling or underfuelling. This results in better combustion, which leads to improved fuel efficiency and reduced emissions, contributing to a greener, more cost-effective operation.

The Intake Valve Seat Ring is also vital in maintaining the longevity of engine components. Over time, engine components such as valves, valve seats, and other related parts can suffer from wear and tear due to the constant heat cycles and mechanical stress. A well-maintained Intake Valve Seat Ring helps protect the intake valve and cylinder head from excessive wear, reducing the need for costly repairs and extending the life of the engine. By ensuring that the valve maintains a proper seal, the ring prevents damage to the valve, cylinder, and other internal engine components.

The Intake Valve Seat Ring is commonly used in various engine types, including gasoline, diesel, and hybrid engines. It is particularly important in performance engines, where precise control over the intake process is critical for achieving high power output and fuel efficiency. In diesel engines, the intake valve and seat ring work together to ensure that the engine receives the correct amount of air to support the combustion of diesel fuel, which is essential for maintaining fuel economy and performance.

Routine maintenance and inspection of the Intake Valve Seat Ring are necessary to ensure its continued effectiveness. Over time, the valve seat may wear down due to constant use, leading to reduced sealing efficiency and potential engine problems. Signs of wear may include rough idle, poor fuel efficiency, or a loss of power. Replacing the Intake Valve Seat Ring before it becomes severely worn can prevent these issues and help maintain the engine’s performance. Regular servicing of the engine’s valve components helps avoid costly repairs and ensures the engine continues to run smoothly.

In conclusion, the Intake Valve Seat Ring is an essential component in ensuring the proper functioning of an engine’s intake system. It plays a key role in providing a tight seal between the intake valve and the cylinder head, contributing to optimal engine performance, fuel efficiency, and longevity. By maintaining the integrity of the engine’s intake system, the Intake Valve Seat Ring ensures that the engine runs efficiently, with reduced emissions and increased power output. Regular inspection and timely replacement of worn valve seat rings are essential for keeping the engine in top condition, preventing damage, and maximizing operational efficiency.

For more information on the regulations and standards governing the use of components like the Intake Valve Seat Ring, you can visit the official website of the Environmental Protection Agency (EPA) at https://www.epa.gov/.

1. Reliable intake valve seat ring for optimal engine performance

2. Durable intake valve seat ring for extended engine longevity

3. High-performance intake valve seat ring for reducing emissions

4. Long-lasting intake valve seat ring for improved fuel efficiency

5. Efficient intake valve seat ring for better engine sealing and power

Bulk Source 720 Intake Valve Seat Ring 20459962, 923976.0378, 0425 2442 For KALMAR DCE 80-100/45E

Direct Factory Pricing | OEM/ODM Customization | GRS Certified Materials