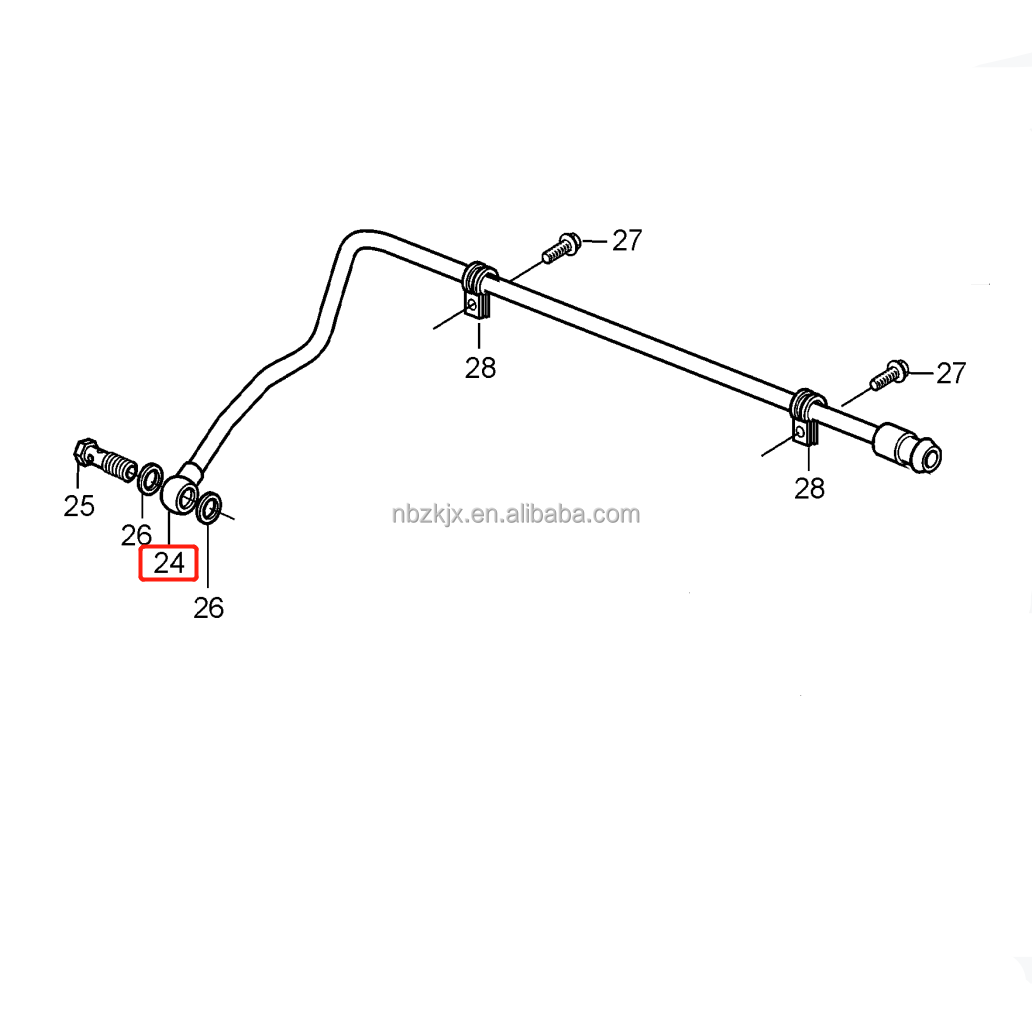

720 Fuel Return Pipe 20539676 923976.0718 Stacker Crane Reach Stacker Parts Accessories For KALMAR DCD 200-300

The Fuel Return Pipe is an essential component in modern fuel systems, playing a critical role in maintaining fuel pressure, efficiency

720 Fuel Return Pipe 20539676 923976.0718 Stacker Crane Reach Stacker Parts Accessories For KALMAR DCD 200-300 - Advanced Analysis

The Fuel Return Pipe is a vital component in the fuel system of both automotive and industrial engines. It is primarily designed to return excess fuel from the fuel injectors or fuel rail back to the fuel tank after it has been used or pressurized within the engine. This pipe helps maintain proper fuel flow and pressure, preventing the fuel system from becoming over-pressurized or contaminated with excess fuel. The Fuel Return Pipe ensures that the engine receives only the required amount of fuel, which is critical for optimal performance, fuel efficiency, and emissions control.

In internal combustion engines, the Fuel Return Pipe is an integral part of the fuel delivery system. After the fuel is injected into the combustion chamber, some fuel remains unused and must be returned to the fuel tank. The return pipe ensures that this fuel flows back without disrupting the balance of the fuel system, which is essential for maintaining the correct fuel pressure and efficient engine operation. By routing excess fuel back to the tank, the Fuel Return Pipe helps to prevent engine stalls, poor performance, or system damage caused by excess fuel pressure.

One of the key advantages of the Fuel Return Pipe is its role in enhancing fuel efficiency. By recirculating unused fuel back to the tank, the fuel system can maintain optimal pressure levels and ensure that fuel injectors receive the correct amount of fuel. This ensures that the engine operates at peak efficiency, with minimal waste and lower fuel consumption. In modern engines, which are designed for greater fuel efficiency and lower emissions, the Fuel Return Pipe plays a crucial role in maintaining these goals.

The Fuel Return Pipe is also important in controlling the temperature of the fuel system. Excessive fuel pressure or flow can lead to increased temperatures, which can cause fuel to vaporize or degrade, negatively impacting engine performance. By effectively returning unused fuel, the Fuel Return Pipe helps maintain a stable temperature within the fuel system, which improves overall performance and prevents issues such as vapor lock or fuel degradation. This function is particularly important in high-performance or heavy-duty engines, where consistent fuel pressure and temperature are crucial for optimal operation.

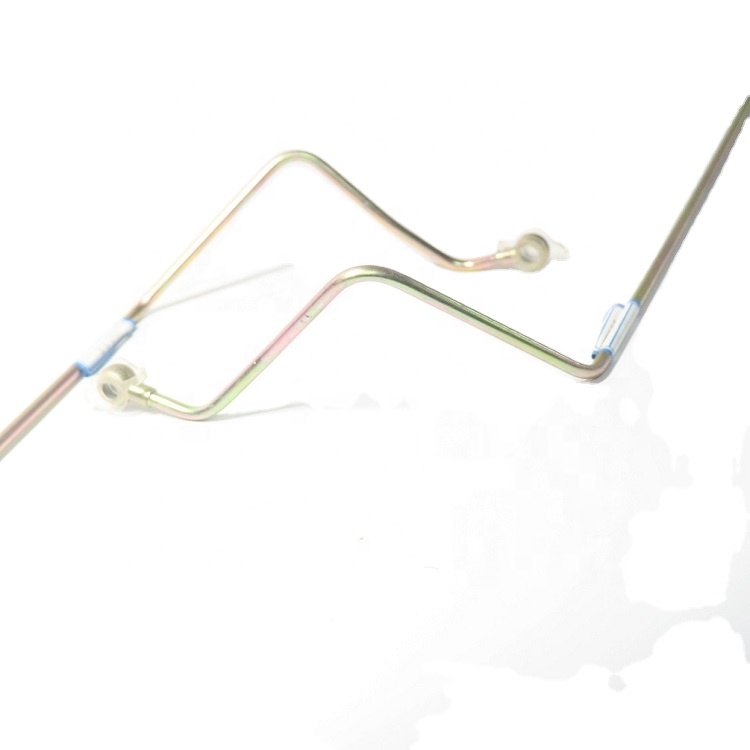

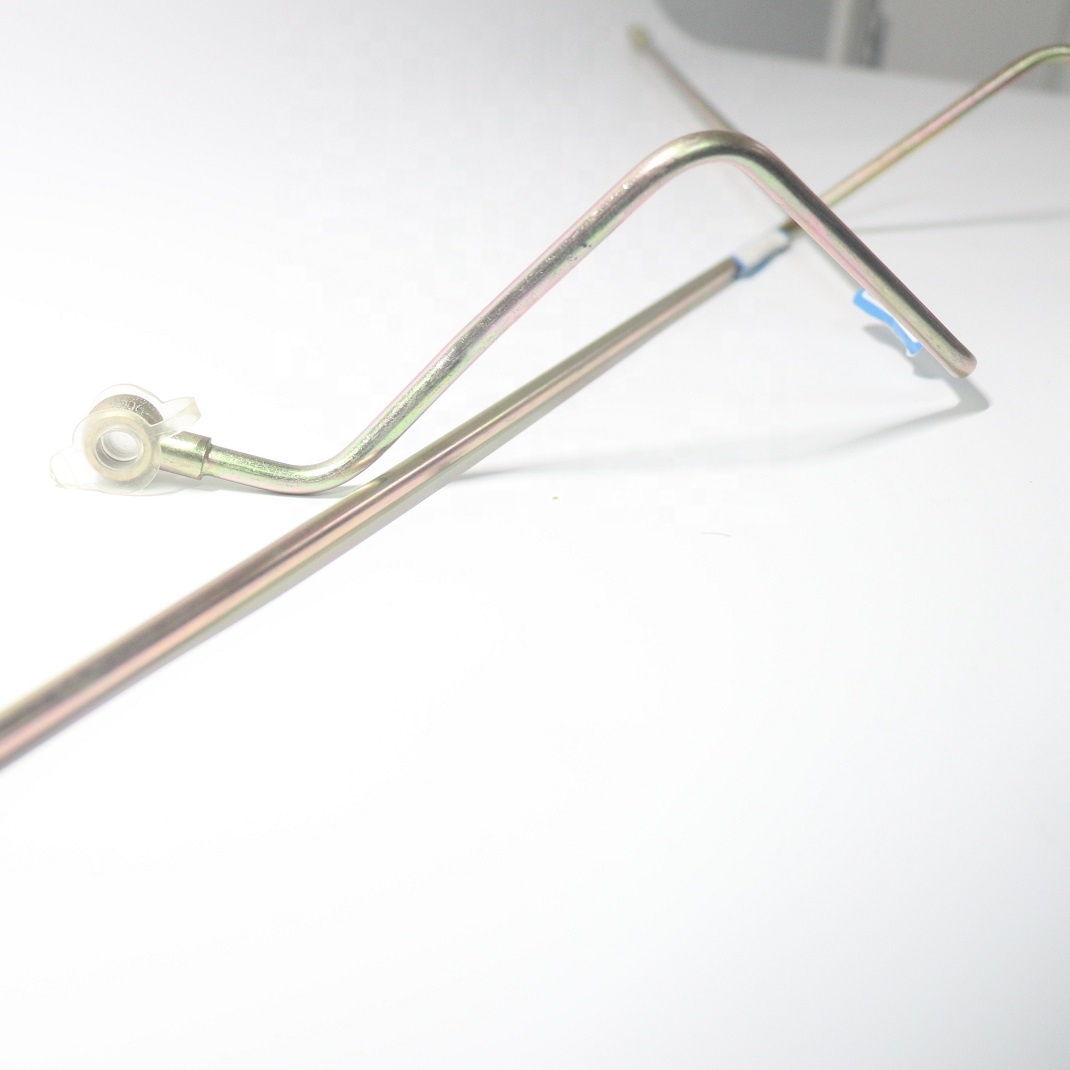

Made from durable materials such as steel, aluminum, or high-quality plastic, the Fuel Return Pipe is designed to withstand high-pressure and high-temperature conditions within the fuel system. The materials used in its construction ensure that the pipe remains resistant to corrosion, wear, and damage caused by exposure to chemicals, heat, or fuel additives. The longevity and durability of the Fuel Return Pipe are essential to the overall reliability of the fuel system, as failure of this component can lead to fuel leaks, pressure imbalances, or engine malfunctions.

In addition to preventing fuel pressure imbalances and improving fuel efficiency, the Fuel Return Pipe also plays a crucial role in ensuring emissions compliance. In modern engines, the fuel system is designed to minimize harmful emissions by controlling fuel injection timing and quantity. The proper functioning of the Fuel Return Pipe helps prevent excess fuel from entering the engine, ensuring that the combustion process remains efficient and emissions remain within regulatory limits. This is particularly important in vehicles and machinery operating in regions with strict emissions standards, where maintaining proper fuel system operation is essential for compliance.

The Fuel Return Pipe is also critical for the smooth operation of diesel engines, where fuel return systems are more complex due to the high pressures and fuel volumes involved. In diesel engines, the Fuel Return Pipe ensures that excess fuel from the injectors is efficiently returned to the tank, preventing the fuel system from becoming over-pressurized or clogged with unused fuel. This helps maintain the performance and longevity of the engine, preventing costly repairs caused by fuel system malfunctions.

In conclusion, the Fuel Return Pipe is an essential component in modern fuel systems, playing a critical role in maintaining fuel pressure, efficiency, and temperature regulation. By returning excess fuel to the tank, it ensures that the fuel system operates smoothly and efficiently, optimizing engine performance and reducing waste. Its durability, precision, and functionality make it an indispensable part of both automotive and industrial engines. Regular maintenance and proper functioning of the Fuel Return Pipe are essential to ensuring the longevity and efficiency of the engine, preventing costly repairs, and maintaining fuel system performance.

For more information regarding the regulations and standards governing the use of fuel components like the Fuel Return Pipe, you can visit the official website of the Environmental Protection Agency (EPA) at https://www.epa.gov/.

Bulk Source 720 Fuel Return Pipe 20539676 923976.0718 Stacker Crane Reach Stacker Parts Accessories For KALMAR DCD 200-300

Direct Factory Pricing | OEM/ODM Customization | GRS Certified Materials