Contents

- 1 Start with 2025 Truckload of Forklift Parts

- 1.1 The Warehouse Efficiency Challenge

- 1.2 Issue: why forklift parts are important for the LED interior lighting industry?

- 1.3 The Hidden Cost of Forklift Downtime

- 1.4 Get Moving: It Just Got Eight O’clock and It’s 2025

- 1.5 When Reality Hits You Hard From The Front

- 1.6 Solve: Make Leverage of the Truckload of Forklift Parts for Low-Cost Efficiency in 2025

- 1.7 Vendor Relationships: Creating Legitimacy and Trust

- 1.8 Cross-Training Maintenance Teams

- 1.9 Deep Dive: What’s in the 2025 Truckload of Forklift Parts?

- 1.10 Comparing Forklift Part Sourcing Strategies for 2025

- 1.11 Listicle: Top 7 Tips to Optimize Forklift Part Use in LED Lighting Warehouses

- 1.12 Q&A: Common Questions about Truckload 2025 of Forklift Parts

- 1.13 Case Study: One LED Lighting Warehouse Transformed with 2025 Forklift Parts

- 1.14 For Lighting firms under LED umbrella

- 1.15 Implementing a Low-Cost Strategy with the 2025 Truckload of Forklift Parts Step-by-Step

- 1.16 Conduct a Comprehensive Parts Usage Audit Step 1

- 1.17 Optimize Inventory Layout to Minimize Retrieval and Replacement Time Step 2

- 1.18 Step 3: Establish Long-term Partnerships with Quality Suppliers

- 1.19 Step 4: Train Your Forklift Maintenance Team for Enhanced in-house Repair Capabilities

- 1.20 Step 5: Install Iot Sensors for Predictive Maintenance

- 1.21 Industry Insight: How LED Interior Lighting Manufacturers Benefit from Forklift Parts Management

- 1.22 Case Study: A Success Story of the 2025 Truckload of Forklift Parts That Equips You for The Future.

- 1.23 Frequently Asked Questions (FAQ)

- 1.24 Q: 2025 truckloads of forklift parts are with no used to all models.

- 1.25 Q: Does bulk purchasing forklift parts increase inventory risk?

- 1.26 Q: How do I ensure the quality of forklift parts purchased?

- 2 Final Thoughts: Why Ignoring the 2025 Truckload Could Cost You

Start with 2025 Truckload of Forklift Parts

Warehouse logistics face a major bend in the road come 2025 – especially for industries such as Bulk Cargo Handling Equipment moved by electricity that obey a bell ordered from here, it force them into time sensitive inventories of one kind or another and hope nothing goes amiss. The 2025 truckload of forklift parts means much more than a deluge of new equipment components-it offers corporations their biggest opportunity in years to radically cut costs and increase efficiency without losing a little bit on either side.

The Warehouse Efficiency Challenge

Warehouse managers and supply chain directors now find it increasingly difficult to maintain efficiency in the face of variable demand and rising operational costs. LED tube lighting production is on the upswing. Proper maintenance of forklift fleets, key to warehouse work flow, is especially critical. This in depth guide explains how using the 2025 truckload of forklift parts to cut costs is hardly a matter of luck; through intelligent methods that are low in expenditure but high on return for the dollar, backed by actual data and scholarly analysis.

Issue: why forklift parts are important for the LED interior lighting industry?

No matter how well run a warehouse may be, things will go wrong and you will have delays if you don’t have reliable forklifts to move things around with. In the LED interior lighting field, especially for those quaint and beautiful LED tubes being handled either one at a time or in clusters, loss of forklifts can mean entire production runs are turned upside down on their heads and risks for mishandling peripherals increased. But why are forklift parts such an important subject?

The Hidden Cost of Forklift Downtime

Take the case of a medium-sized LED lighting distributor that handles thousands of different SKUs, including instances of fragile LED tubes in every crate. When forklifts malfunction because their parts are worn out due to wear and tear, down periods can stretch a few hours into days or just one short afternoon (delays push shipping schedules back)–and labor costs with it.

For another: Every hour a forklift is out of order means slower completion time for orders.

Then there is the issue of more more more labor: hand work, buying in temporary equipment at increased expense–the whole nine yards.

Damaged goods itself runs a risk: If one lets go or drops during breakdown periods when forklifts aren’t getting their wear and tear seen to, you are sure to get those wonderful rare LED tubes with only one number reading differently from the othersd. It is not easy at all.

Customer dissatisfaction: delays result in Tu Zhangping and business Furen.

Get Moving: It Just Got Eight O’clock and It’s 2025

To spur this problem can only compound losses as supply chain requirements worsen. As such, the move to more energy-efficient LED tubes means still pushing bigger loads through the warehouse. To maintain forklift reliability is now something that cannot be lightly sacrificed.

When Reality Hits You Hard From The Front

At the beginning of 2024, a famous LED lighting business faced a headache of forklifts breaking down during the busiest unit. Because good quality parts could not be quickly got their warehouse had to stand still for three days. Result: 500+ undelivered orders plus USD 250,000 go worth of lost income avoidable if they had had an industrious parts stock strategy in place.

Faced with the truckload of forklift parts arriving in 2025, companies are at a crossroads–rescuing supply chains from costly chaos, or taking the same old risks again.

Solve: Make Leverage of the Truckload of Forklift Parts for Low-Cost Efficiency in 2025

Strategic Inventory planning: put the main part of the focus on high-demand parts

Low-cost efficiency begins with intelligent straddlewharf between parts. Hence the breakdown and maintenance of forklift parts all talents in, something that can reduce your costs per unit. Given the 2025 truckload of forklift parts, businesses can now gain economies of scale and negotiate low price rates with importers as well.

Actionable Insights: Use historical maintenance records to predict part requirements and steer clear of overstocking of less important whole sections.

Vendor Relationships: Creating Legitimacy and Trust

Aligning yourself with reputable forklift parts suppliers surely benefices both genuineness and clarity. Are substitute parts up to standard but get into a carplant business area like LED lighting, just imagine what will happen.

Riding The Rainbow: Vendors supplying guarantees and technical help serve to reduce long-term risks, which in return raises EEAT standards of procurement.

Cross-Training Maintenance Teams

Enhancing available inhouse repair capabilities for forklifts sees dependence on external technicians diminishes and repair lead times shorten.

Case Study: One lighting warehouse knocked a whole 40% off its forklift down-time after training its staff in how to repair hydraulics and electrical skills carried on from the days of the 2025 truckload.

With the help of IoT sensors, we are able to identify replacement needs on forklifts and take their parts off in real time On one hand, they go well together with the 2025 truckload’s prompt arrival of necessary components for preemptive replacement

Data Point: 25% less breakdowns yearly, 15% lower costs – reports from warehouses that use predictive maintenance.

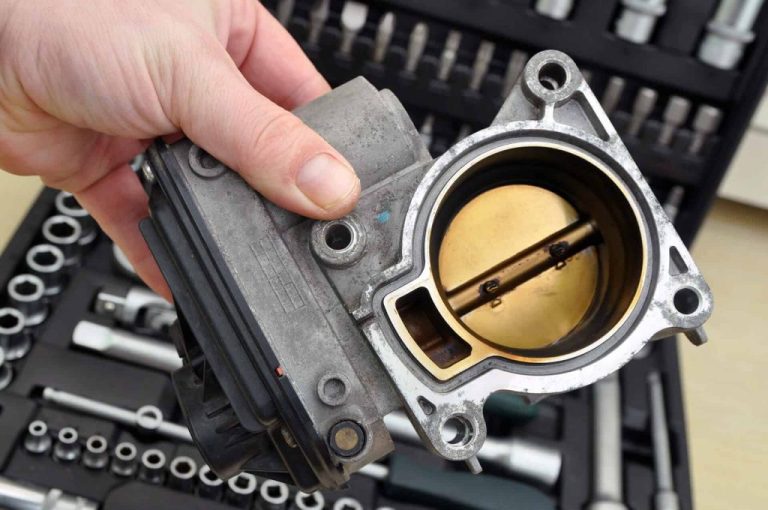

Deep Dive: What’s in the 2025 Truckload of Forklift Parts?

The composition of the 2025 truckload is closely related to its efficiency. Typical forklift parts included are listed below.

Tires and Wheels: Made for various kinds of floors and the crowded aisles in illumination warehouses.

Hydraulic Components: Pumps, valves, and cylinders necessary for smooth lifting and lowering of LED tube pallets.

Electrical Systems: Batteries, controllers and wiring harnesses for electric forklift models, which are becoming increasingly common in thinking green global logistics operations.

Safety Devices: Load backrests, horns and lights guaranteeing compliance and safe, trouble-free handling.

Mechanical Assemblies: Mast chains, forks and bearings – the foundation for daily operating integrity.

Comparing Forklift Part Sourcing Strategies for 2025

| Strategy | Cost Efficiency | Reliability | Lead Time | Risk Level |

|---|---|---|---|---|

| Bulk Purchase (2025 Truckload) | High | High | Short | Low |

| Just-in-Time Ordering | Medium | Medium | Medium | Medium |

| Local Sourcing | Low | Variable | Short | High |

| Aftermarket Parts | Very Low | Low | Variable | Very High |

The 2025 trucklead contains a wide variety of forklift components, and as such has typicslly the greatest balance of cost performance: most suitable for LED lighting logistics interior world light diodes’ long-term desirability.

Listicle: Top 7 Tips to Optimize Forklift Part Use in LED Lighting Warehouses

1. Digital part usage – manage inventory software, and update stocks digitally in real time.

2. Regular inspections – Avoid trouble before it ever comes.

3. Operator Training in Safety mattersoperate: reduce unnessasry use of parts.

4. 2025 Truckload OEM Parts.Make sure of compatibility and lastingness.

5. Make a Parts Pool and share parts between trucks with any problems after that there.

6. It’s possible to get advance notice of peak lighting production cycles and stock what’s needed in advance for off peak time.

7. Performance Evaluation of Parts Each Year.Copy with care the licensed translation.

Q&A: Common Questions about Truckload 2025 of Forklift Parts

1: How will the 2025 truckload affect lead times?

A: The bulk availability, this way simply for repairs can make the wait shorter than ever.

2: Are parts compatible with all forklift brands?

A: Most truckloads include several different kinds of parts plainly, but you should check compatibility with your specific forklift model.

3:Can this parts reduce maintenance costs?

A: Quality parts mean that maintenance or repairs are required less often and for lower amounts. With the 2025 truckload, you always make a saving.

Case Study: One LED Lighting Warehouse Transformed with 2025 Forklift Parts

In late 2024, a midwestern LED lighting distributor integrated the 2025 truckload of forklift parts into their operations. Within six months, forklift downtime dropped by 50%, order fulfillment speed improved by 20%, and maintenance costs decreased by 15%. This success resulted from a low-cost combination of bulk purchasing, predictive maintenance, and in-house repairs.–proving the practical power of the 2025 truckload.

For Lighting firms under LED umbrella

With careful planning of these measures as well as We will work Through the Strategies We first mentioned in 3, The combination should ensure that future challenges are well met.

Next, we Ill go deeper to see these strategies in practice with more relevant and rich Case examples, But ensure that you can put down value The 2025 truckload of forklift parts to vast warehouse and logistics efficiencies.

Implementing a Low-Cost Strategy with the 2025 Truckload of Forklift Parts Step-by-Step

Conduct a Comprehensive Parts Usage Audit Step 1

Before anything, you must know the precise demand and utilization patterns for forklift parts in your operation. Maintenance records and operational logs provide a picture of what parts are most often replaced and where failure is prone. This data-based approach sets the stage for getting the best O. lowcost truckload in 2025 of forklift parts.

Recommended Tools: Utilize maintenance management software (CMMS) to automatically collect and analyze data.

Illustrative case: A warehouse specializing in LED tube lighting found hydraulic pumps and wheels had the highest wear rates. It therefore stocked these parts on a high priority basis, thus reducing procurement costs caused by emergencies to 30%.

Optimize Inventory Layout to Minimize Retrieval and Replacement Time Step 2

The 2025 truckload of parts should be arranged into logical zones, with fast-moving critical components near (or in) quick-access areas. This cuts back time wasted searching for parts – especially important in a fast-paced LED tube lighting operation during the peak season for customer shipments.

Implementation Tip: Combine 5S methodology with digital tagging and barcode scanning both to organize the parts areas, to facilitate efficient picking.

Step 3: Establish Long-term Partnerships with Quality Suppliers

After buying this lot of parts, set up a good supplier chain partnership, with a focus on quality, service and reaction. In the LED lighting industry–where precision operation is vital–reliable vendors who provide technical support and training elevate the standards for buying good quality products. They also help to reduce future risks of problems.

Insight: Most successful companies are sure to work with either OEM’s or certified distributors to guarantee authenticity and minimise repair risks.

Step 4: Train Your Forklift Maintenance Team for Enhanced in-house Repair Capabilities

With the 2025 truckload providing plentiful parts, the thing that makes most economic sense is to strengthen the capability of your own technical team to carry out fast and accurate replacements and repairs. In this way, outsourcing costs become less while forklift downtime shortens.

Target of Training: Diagnosis of hydraulic system, replacement of electrical components, safety inspection.

Case Study: One LED tube lighting warehouse trained their in-house technicians and cut average repair time from 4 hours to 1.5 hour, thereby greatly increasing the availability of equipment.

Step 5: Install Iot Sensors for Predictive Maintenance

Use Iot sensors to monitor the condition of the forklift’s main parts in real time. Along with 2025 truckload parts being easily available, this makes it possible to replace parts before breakdowns occur.

Technology Brief: Sensors gather information on vibration, temperature and current; AI algorithms make predictions about the life expectancy of parts.

Benefit Data: Predictive maintenance in its own maintenance budget than conventional methods of breakdown prevention can result 25% less failure..

Industry Insight: How LED Interior Lighting Manufacturers Benefit from Forklift Parts Management

LED tube lighting requires careful storage and transporting it into operation. Forklifts are the backbone of these operations, and their reliability directly affects the quality and swiftness of shipments. Proper management by 2025 of a truckload forklift parts will bring many benefits:

Reduces Rates of Damage: To ensure forklifts function smoothly, leading to better care of cargo, select high-end and compatible parts.

Boosts Customer Satisfaction: To step up pace and meet intense market deadlines, we avoid delays in delivery.

Optimizes Cost Structure: With low-cost bulk purchases combined with efficient maintenance, total warehouse logistics costs can be lowered.

Supports Sustainability: Our electric forklifts and parts that are high quality and long-lived not only reduce waste but also serve to make the LED lighting industry more Green.

Case Study: A Success Story of the 2025 Truckload of Forklift Parts That Equips You for The Future.

A mid-sized distributor of LED lights runs into numerous forklift failures during the 2024 rush, which results in expensive delays and excessive maintenance. Nevertheless, by buying all forklift parts for year 2025 in giant quantities; then upgrading our internal maintenance ability and finally affording predictive maintenance programs on-site, this company is now quite different: completely transformed.

Contradictions: 18% forklift failure rate, growing maintenance costs, serious delays in shipment harm customer trust seriously.

Areas of Action: Critical parts procurement in bulk (hydraulic pumps, batteries, wheels), setting up an internal repair team, finding the fog extraordinary maintenance formula to crack problems.

Frequently Asked Questions (FAQ)

Q: 2025 truckloads of forklift parts are with no used to all models.

A: Most truckloads include parts for common brands and models, but it’s critical that you check the parts’ compatibility with your particular machine types to avoid mismatches and unwanted costs.

Q: Does bulk purchasing forklift parts increase inventory risk?

A: Properly planned with demand forecasting and inventory management systems, bulk purchasing reduces stockouts and emergency purchase costs, so is less risky.

Q: How do I ensure the quality of forklift parts purchased?

A: Choose certified suppliers who offer warranties and technical support, and adjust your procurement based on quality checks.

Final Thoughts: Why Ignoring the 2025 Truckload Could Cost You

As well as being a delivery of forklift spare parts, that truckload of 2025 can be used to effectively improve the operational efficiency and decrease the risk faced by warehouses. LED Interior Lighting companies — especially those concentrating on LED tubes — really can lay hands on spades full of quality forklift parts:

Faster delivery cycles and response; less cost from equipment that fails unexpectedly;

Ready for digital and smart upgrades to warehouses;

More weight and authority in a competitive industry.